Mold mechanism driven by up-down movement arm

A mold mechanism and moving arm technology, applied in the field of mold mechanism, can solve the problems of slow running speed of the cylinder, slow running speed of the cylinder and the oil cylinder, and low lifting speed of the bottom mold, so as to improve the speed and precision of mold opening and closing, and optimize the product structure , the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

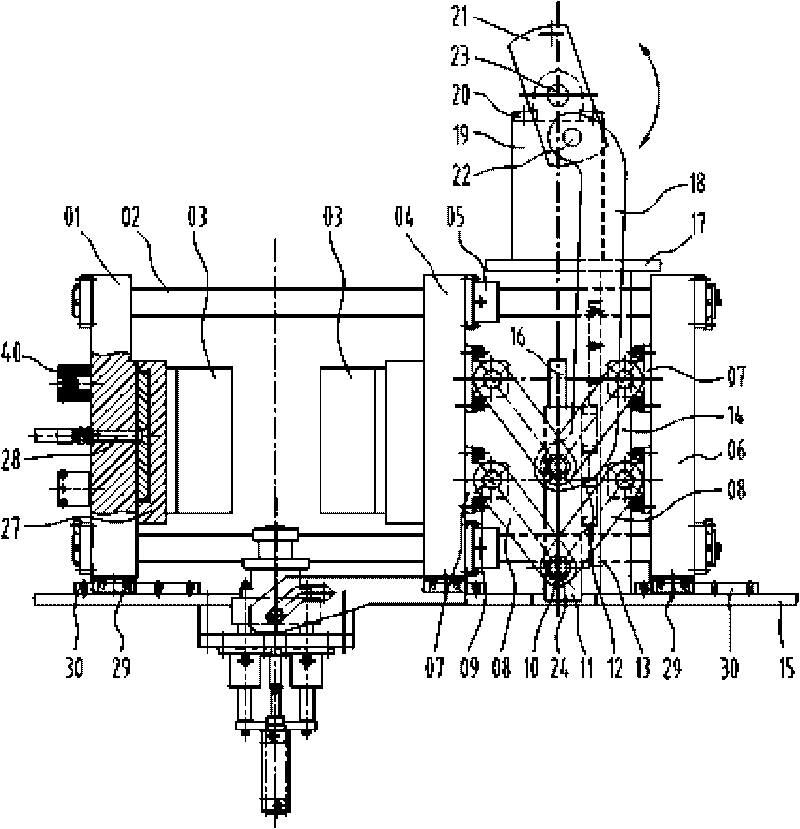

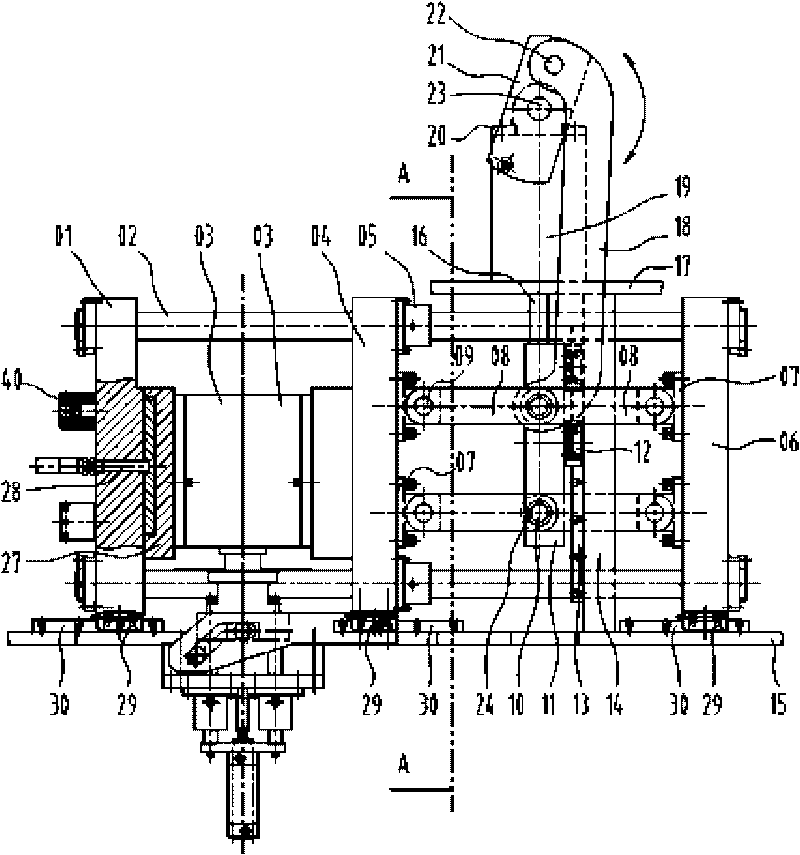

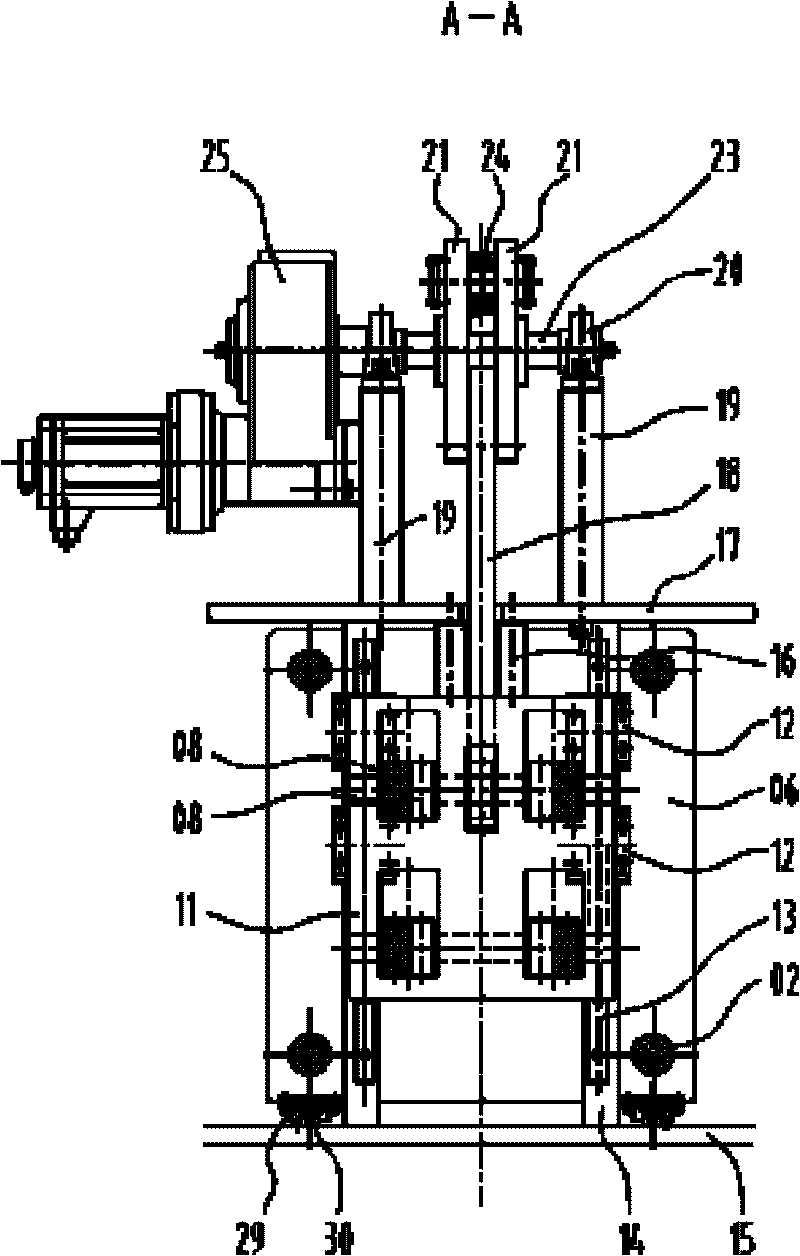

[0027] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a mold mechanism driven by an up and down moving arm described in this embodiment includes a frame 15, a left template 01, a middle template 04, a bottom template 34, a connecting rod 02 and a right template 06, and the left template 01 and the right template 06 is fixed on both ends of the connecting rod 02, and the two can be linked synchronously. The middle template 04 is located between the two and is slidably arranged on the connecting rod 02 through the guide sleeve 05. Between the middle template 04 and the right template 06 A crank arm mechanism is provided, and the crank arm mechanism is two sets of parallel crank arms 08. The middle of the crank arms 08 is hinged on the lifting plate 11 through the long pin shaft 10 and the joint bearing 24, and the two ends are arranged on the crank arm support The short pin shaft 09 and the joint bearing on the 07 are hinged on the middle template 04 and the right...

Embodiment 2

[0038] like Figure 5 As shown, the mold mechanism described in this embodiment is driven by an up and down moving arm. In the case where the mold clamping speed is not high, the pneumatic or hydraulic device 26 can be used as the driving power to make the driving arm 18 move up and down. , the rest of the structure and working process are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com