Process for manufacturing decorative veneer plywood

A production process and decorative sticker technology, applied in the direction of manufacturing tools, wood veneer bonding, wood processing appliances, etc., can solve problems such as poor flatness, affecting the strength and sensory quality of decorative panels, and paper bubble peeling, etc. Achieve high peel strength, ensure its own strength and sensory quality, and good flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

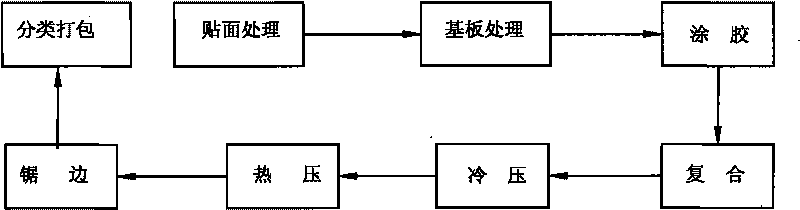

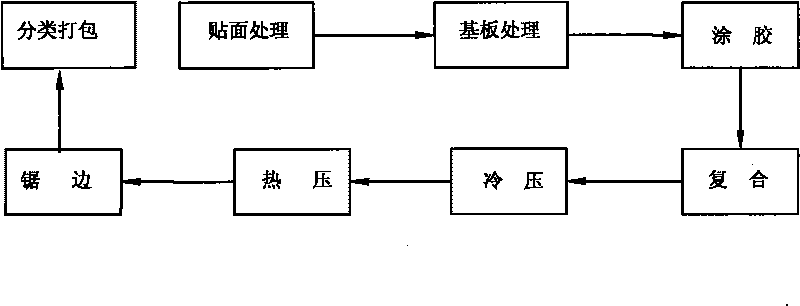

[0008] Embodiment 1: with reference to attached figure 1 . The invention relates to a manufacturing process of a decorative veneer, which includes a base plate, and the base plate is a wood board or a multi-layer board. (1) Facing treatment: First, the paper or skin to be pasted is rolled by a flat press machine for 25 to 30 seconds at a temperature of 150°C to 170°C, then the paper or skin is taken out and placed flat, and the paper or skin Spray mist on the surface and cool it to prevent it from rolling up; (2) Substrate treatment: After greasing and drying the substrate surface, set a sander for polishing, so that the flatness of the substrate surface reaches that of MDF. Flatness; (3) Composite: apply glue on the treated substrate surface, paste the treated paper or skin on the substrate surface, put it into a cold press for pressing, and take it out for 30 to 40 minutes, then take it out and place it Put it into a hot press machine for pressing, the time is 8-10 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com