Plant source green and environment-friendly solvent and preparation thereof

A green, environmentally friendly, plant-sourced technology, applied in botany equipment and methods, plant growth regulators, animal repellents, etc., can solve the problems of high price, limitation, and unsatisfactory solubility, and achieve low price and low energy consumption. The effect of less and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

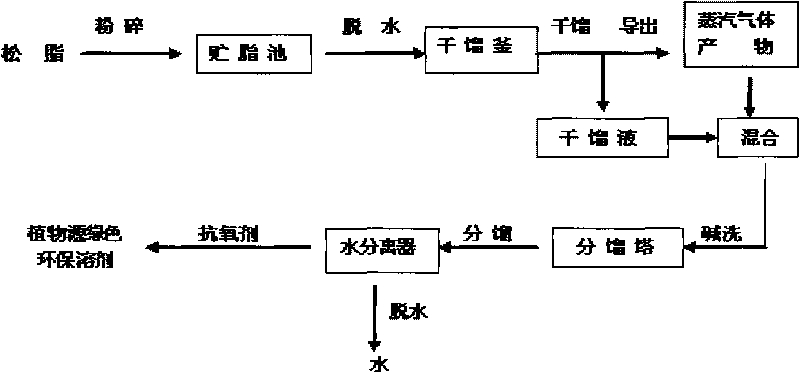

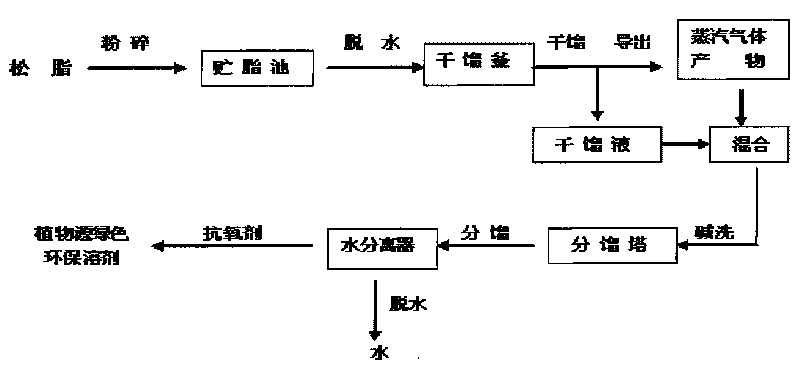

Method used

Image

Examples

Embodiment 1

[0040] Weigh 100 kilograms of rosin, put it into the fat storage pool after crushing, and remove the water; under the condition of being isolated from the air and at a temperature of 300 ° C, dry distillation and cracking of the turpentine for 15 hours, and simultaneously condense the gaseous product produced by the cracking, and mix with The liquid products produced by cracking are collected together to obtain the cracking solution; the cracking solution is washed with 10 kilograms of 5% lye in mass concentration, and the oil and water are separated by standing, and the separated oil phase is fractionated by a fractionating tower, and the fraction between 80 and 260 ° C is collected ; Water separator dehydration (0.38% by mass of water in the cut), obtains 63 kilograms of cuts; Adds 0.64 kilograms of antioxidant 2 in the cut, and 6-di-tert-butyl-p-cresol dissolves evenly, prepares and obtains plant source green Environmentally friendly solvents.

[0041] The composition of th...

Embodiment 2

[0043] Weigh 100 kg of turpentine, crush it, add it to the fat storage tank, and remove the water; mix the dehydrated rosin with 1 kg of MGG catalytic cracking catalyst, and dry distillation and cracking for 10 hours under the conditions of air isolation and temperature of 260°C At the same time, the gaseous product produced by cracking is condensed and collected together with the liquid product produced by cracking to obtain a lysate; the lysate is washed with 8 kilograms of mass concentration of 6% lye, left to stand for oil-water separation, and the separated oil phase passes through Fractionation tower fractionation, collecting fractions between 80~260°C; water separator dehydration (0.37% of water in the fractions by mass), to obtain fractions of 72 kg; add 1.10 kg of antioxidant 2,6-di-tert-butyl to the fractions The base p-cresol is uniformly dissolved, and the plant source green solvent is prepared.

[0044] The composition of the detected plant source green solvent is...

Embodiment 3

[0046] Take by weighing the rosin of 100 kilograms of quality, add in the fat storage tank after pulverizing, slough off moisture; 4 [SiW 12 o 40 ]·xH 2 Mixed with O silicotungstic acid (1≤x≤12) catalyst, under the conditions of air isolation and temperature of 260 ° C, dry distillation and cracking for 10 hours, and at the same time, the gas product is condensed from the top of the dry distillation tank, and the liquid produced by the cracking is the same And collect, obtain lysate; With 15 kilograms of mass concentration be 3% lye washing lysate, leave standstill oil-water separation, the oil phase that separates is fractionated by fractionating tower, collects the cut between 80~260 ℃; Water separator dehydration ( The mass percent of water in the cut is 0.37%), obtains 73 kilograms of cuts; Add 1.11 kilograms of antioxidant butyl hydroxyanisole to the cuts and dissolve evenly, prepare the plant source green solvent.

[0047] The composition of the detected plant source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com