Manufacturing method of motor stator coils

A manufacturing method and motor stator technology, which are applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as temperature rise, coil burnout, cracking, etc., achieve good heat dissipation, prevent coils from being damaged, Effect of Enhanced Motor Overload Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

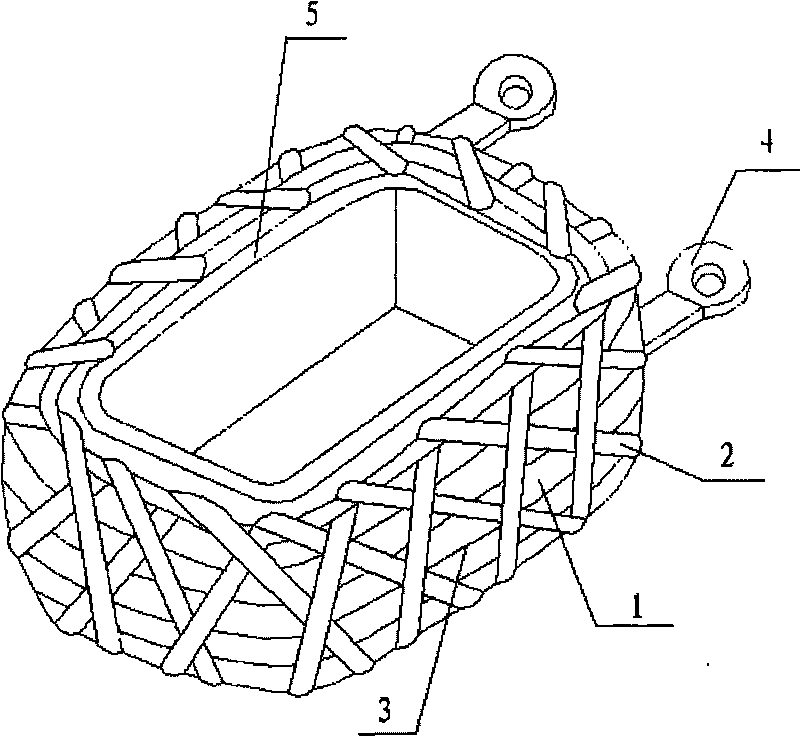

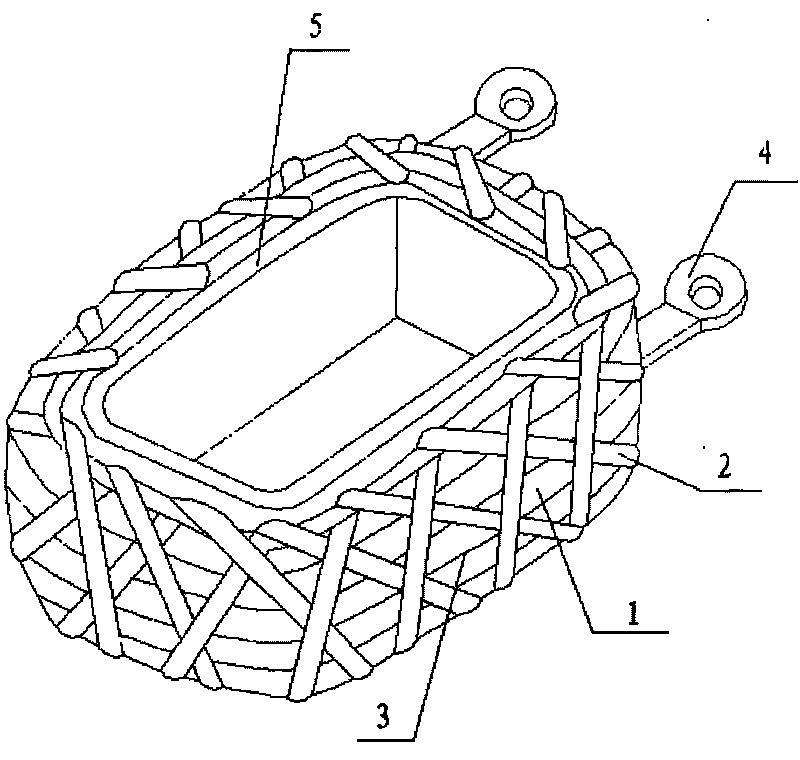

[0008] A motor stator coil manufacturing method of the present invention is composed of coil 1, mesh insulation 2, insulating varnish layer 3, wiring nose 4 and coil lining frame 5; coil 1 is wound outside coil lining frame 5, and coil 1 is wound type, wind the winding direction of the coil 1 and the axial direction of the coil 1 with a binding insulating tape at a certain angle to form a mesh insulation 2; soak and dry the coil 1 in turn with insulating paint for two to three times; the terminal lug 4 is fixedly connected to both ends of the coil 1 head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com