Suction disk loading device and optical pickup unit core of same

A technology of optical pickup and movement, applied in instruments, recording of information on magnetic disks, magnetic recording, etc., can solve the problems of the roller shaft not working normally, occupying the descending space of the roller shaft, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0168] (Embodiment 1, optical pickup core)

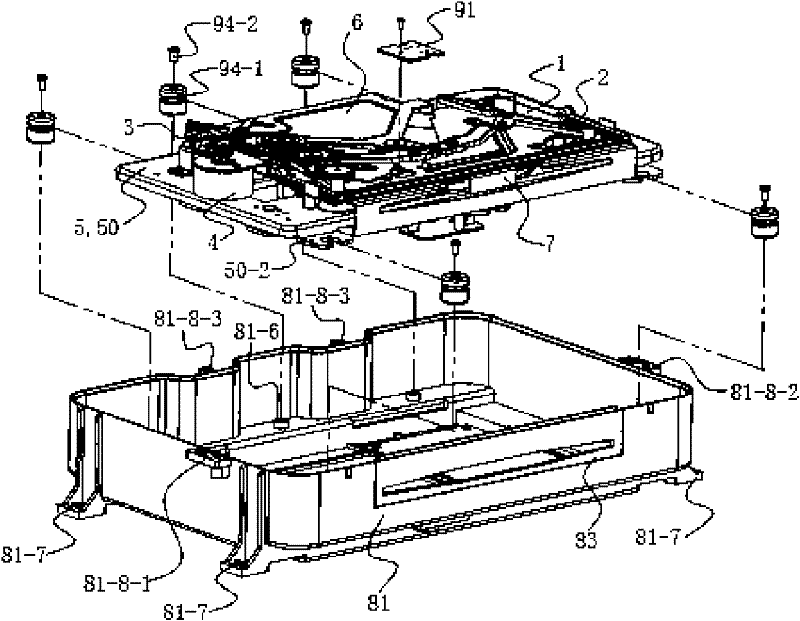

[0169] See Figure 21 to Figure 26 , The optical pickup core 5 of the present embodiment includes a base 50, a spindle motor assembly 51, a turntable assembly 52, six slide bar seats 53, a first optical pickup driving component and a second optical pickup driving component.

[0170] See Figure 17 , The base 50 is an integral stamping made of steel, including a bottom plate 50-1 and six shock absorber connection seats 50-2.

[0171] The overall shape of the bottom plate 50-1 is rectangular, with downward folded edges around it, and a long strip-shaped central hole 50-6 as an optical disc reading hole is opened in the center.

[0172] The 6 shock absorber connecting seats 50-2 are divided into two groups, each with 3 shock absorber connecting seats. The left part of the front side, the middle part of the front side and the right part of the front side; the second group of shock absorber connecting seats are equally spaced and conn...

Embodiment 2

[0197] (Embodiment 2, optical pickup core)

[0198] The rest of the optical pick-up movement of the present embodiment is the same as Embodiment 1, the difference is: the middle part of the base plate 50-1 is connected front and back, and the strip central hole 50-6 on the base plate 50-1 is divided into 2 are located on the left and right sides of the bottom plate 50-1, respectively. The spindle motor 51-1 of the spindle motor assembly 51 is fixed on the center of the bottom plate 50-1 by its motor housing.

Embodiment 3

[0199] (Embodiment 3, Suction Disk Loading Device)

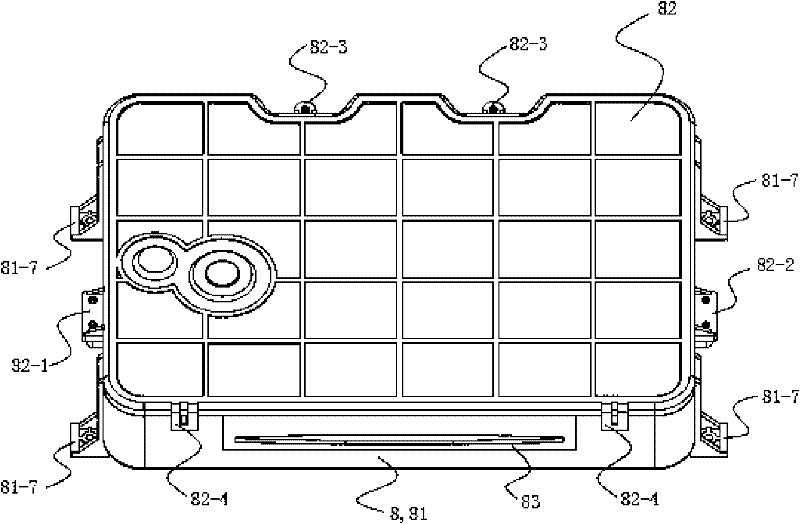

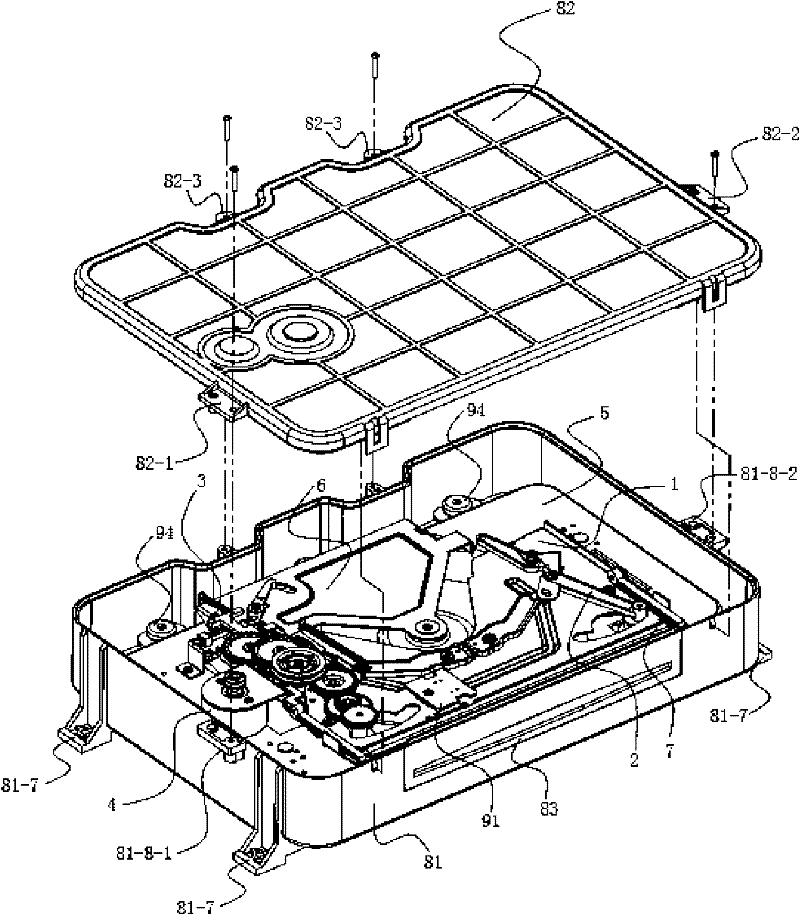

[0200] See figure 2 , Image 6 and Figure 17 , the suction-type disk loading device of the present embodiment includes an upper cover assembly 1, an in-and-out disk mechanism 2, a control assembly 3, a transmission mechanism 4, an optical pickup core 5, a pressure plate assembly 6, a baffle assembly 7, a housing 8, a receiving A circuit board 91 , a transmitting circuit board 92 , two wiring boards 93 and five shockproof connectors 94 .

[0201] The optical pickup core 5 in this embodiment is obtained from Embodiment 1. The optical pick-up core 5 also includes 2 blocking posts 50-5 for blocking; the base 50 of the optical pick-up core 5 also includes the left shaft seat plate 50-3 and the right shaft seat plate 50 connected on the base plate 50-1 -4. The left shaft seat plate 50-3 is connected to the base plate 50-1 from top to bottom, and is located on the left of the rear portion of the bottom plate 50-1, and the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com