Multi-rope winding type stage hoisting machine

A winding type, hoisting technology, applied in the direction of lifting equipment, transportation and packaging in mines, can solve the problems affecting the safety and reliability of braking, the production and processing of the main shaft, the impact of transportation, and the large area of the brake. The effect is safe and reliable, avoiding the problem of multi-layer transition, and shortening the installation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

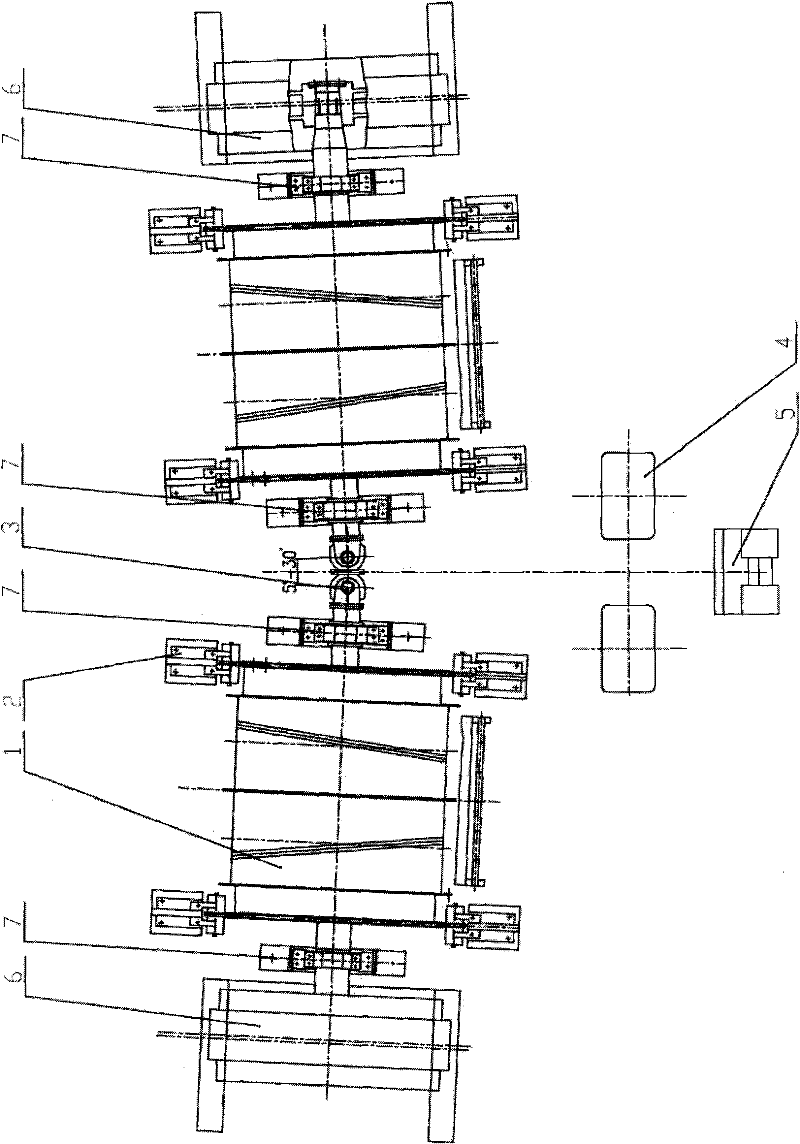

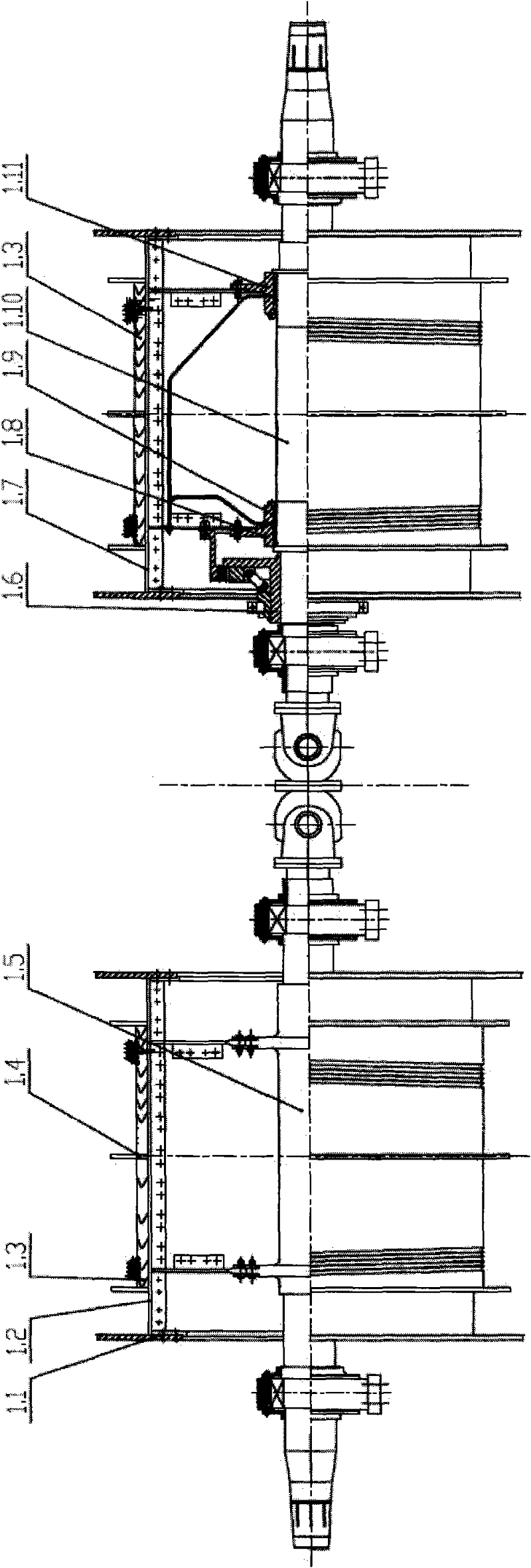

[0039] Such as figure 2As shown: in the multi-rope winding stage hoist of the present invention, two motors 7 are respectively synchronously and directly connected to the floating drum main shaft 1.12 and the fixed drum main shaft 1.6 to drive the entire main shaft system 1, and the main shaft device passes through the universal The coupling is connected so that the main shaft 1.12 of the traveling reel and the main shaft 1.6 of the fixed reel realize synchronous movement, and four disk brake devices 2 are arranged symmetrically on the left and right sides of the traveling reel 1.9 and the fixed reel 1.3 respectively, and the above is controlled by the console 5 For control, the hydraulic station provides brake oil pressure for the multi-rope winding hoist.

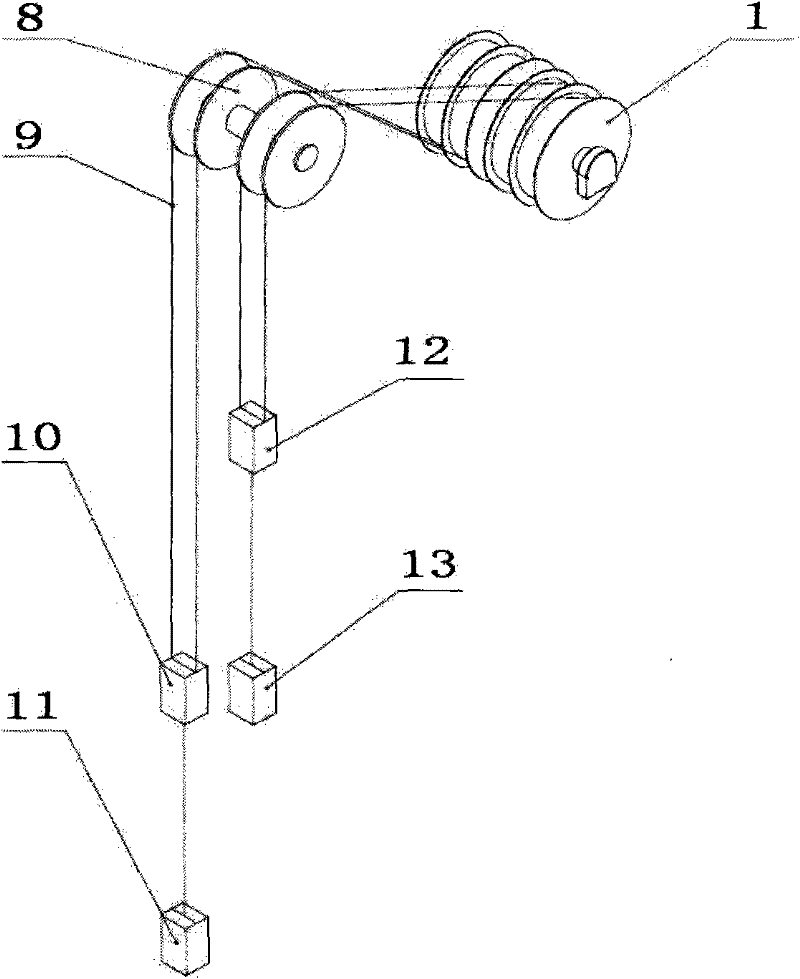

[0040] like figure 1 Shown: the multi-rope winding stage hoist of the present invention, the steel wire rope is fixed on the main shaft device 1, connected with the floating reel top container 10 and the fixed reel top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com