Process for manufacturing 12OZ thick copper multilayer circuit board

A manufacturing process and circuit board technology, which is applied in the field of multilayer circuit board manufacturing process, can solve the problems of obvious barrier effect, uneven heat transfer, and affecting hole quality, so as to reduce side erosion effect, uniform pressure distribution, and improve etching factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A manufacturing process of a 12OZ thick copper multilayer circuit board, including inner layer etching, pressing and drilling processes,

[0023] Among them, in the inner layer etching process, the CU in the acidic copper chloride etching solution is controlled 2+ The concentration is 150±20g / l, the temperature is 50±3℃, the total acidity is 2.8±.6N, the specific gravity is 1.30±0.10, the etching speed is 1.2±0.3m / min, the number of etching is 4 times, and the plate is turned over after each etching face once;

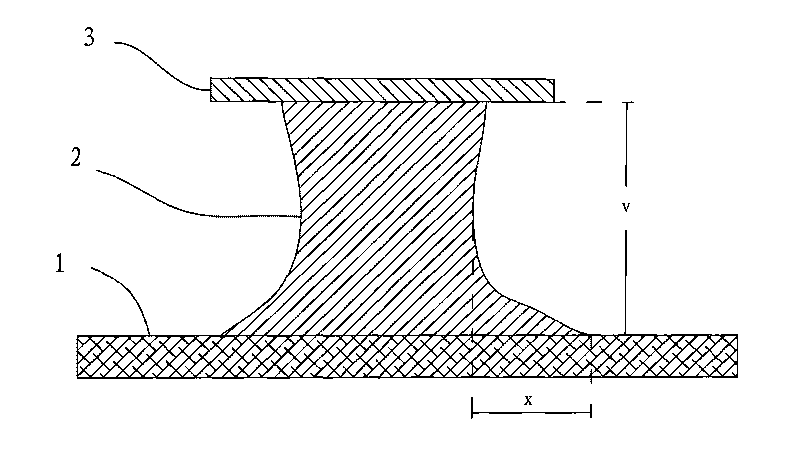

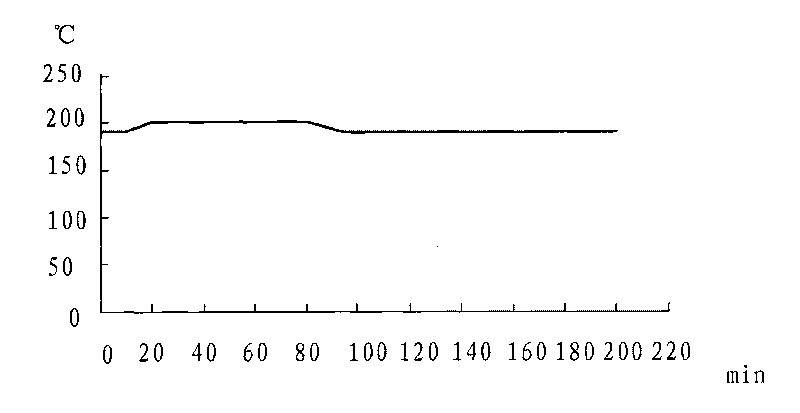

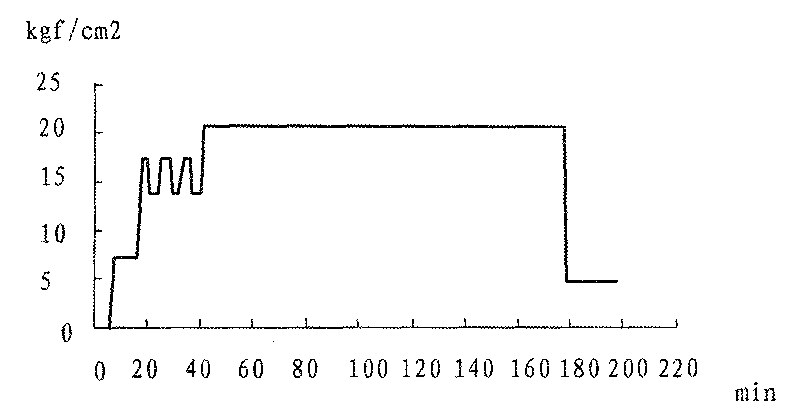

[0024] In the pressing process, it includes a hot pressing step and a cold pressing step, wherein the hot pressing time is 200min, the system is vacuumed and the absolute pressure is 10mbar between 5-95min, and the maximum pressure of the pressing plate is 21.42Kgf / cm 2 , the temperature is 190°C; the cold pressing time is 110min, and the maximum platen pressure is controlled at 18.36Kgf / cm 2 ;

[0025] In the drilling process, when the diameter of the pre-dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com