Pole replacing operation method for fixed double aluminum alloy holding poles

An aluminum alloy and pole-holding technology, which is applied in the installation of electrical components, overhead lines/cable equipment, cables, etc., to achieve the effects of improving power supply reliability, facilitating safety control, and saving construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

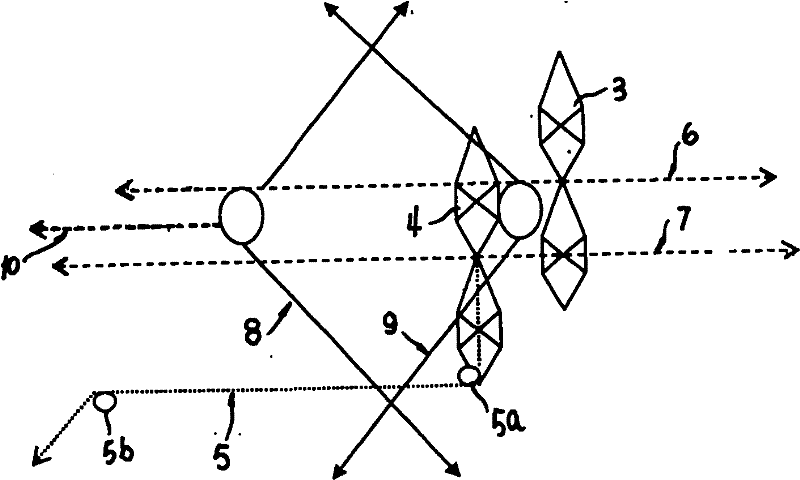

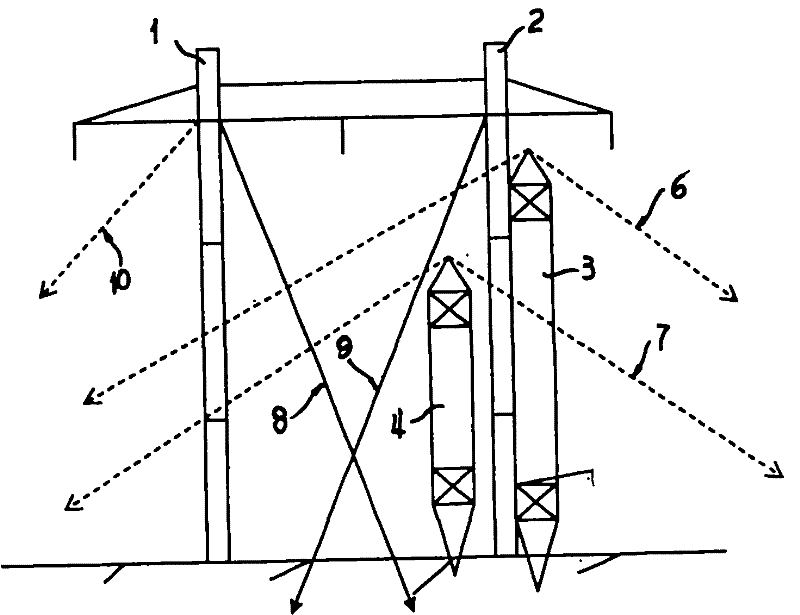

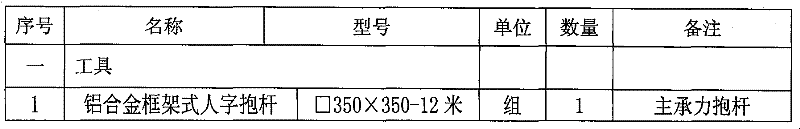

[0014] figure 1 figure 2 It is shown that the present invention includes a left rod 1, a left rod cable 8 and a right rod 2, and a right rod cable 9 for erecting power lines. The crack defect of the right rod occurs in the middle and lower section, and proceed as follows:

[0015] a. On the left and right sides of the right pole 2, a herringbone auxiliary pole 4 and a herringbone main bearing pole 3 are respectively erected, and the middle parts of the two wind ropes 7, 6 are respectively fixed on the top of the auxiliary pole and the main bearing pole. , The two ends of the two wind ropes 7, 6 are respectively fixed on the left and right ground of the auxiliary pole and the main bearing pole, and the two wind ropes 7, 6 are perpendicular to the power line of the pole;

[0016] b. A temporary wind rope 10 is tied to the upper part of the left pole 1, and the other end of the wind rope is fixed on the ground on the left side of the left pole, and the temporary wind rope is perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com