Reinforced insulation composite material for exterior wall and application method

A technology of external wall insulation and composite materials, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of low flame retardancy level of polystyrene board, reduced thermal insulation effect, poor fire protection level, etc., to avoid cold ( Thermal bridging phenomenon, easy maintenance, low thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

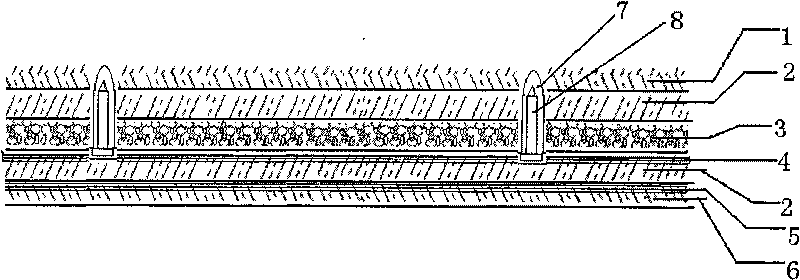

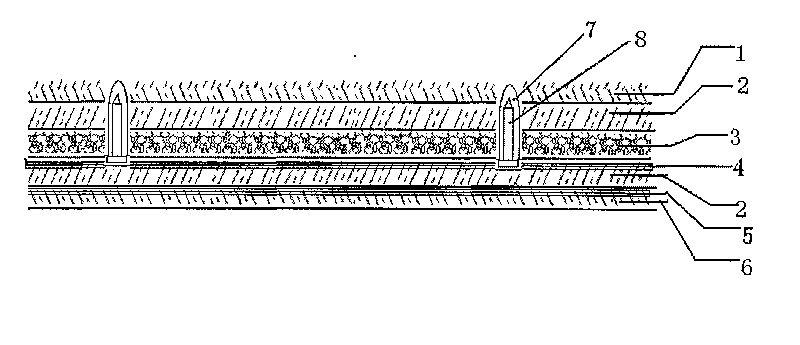

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] With reference to the accompanying drawings, the external wall thermal insulation composite material is that the inner and outer layers of the hard foam polyurethane layer 3 are sequentially combined with an inorganic hollow microbead polymer composite thermal insulation layer 2, and the outer inorganic hollow microbead polymer composite thermal insulation layer 2 is combined with the rigid foam polyurethane layer. A steel wire mesh 4 and anchor bolts are provided at the junction of the layers 3, and wall bricks 6 are combined on the outer layer of the inorganic hollow microbead polymer composite thermal insulation layer 2 of the outer layer. Galvanized steel wire mesh 4 can greatly increase the strength of the overall thermal insulation material of the composite exterior wall, making it not easy to crack, loosen and fall off. And after smearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com