Induction heating cooker

A technology of induction heating and cooker, applied in induction heating, induction heating device, electric/magnetic/electromagnetic heating, etc., can solve the problem of ineffective heating and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0049] 1.1 Structure of induction heating cooker

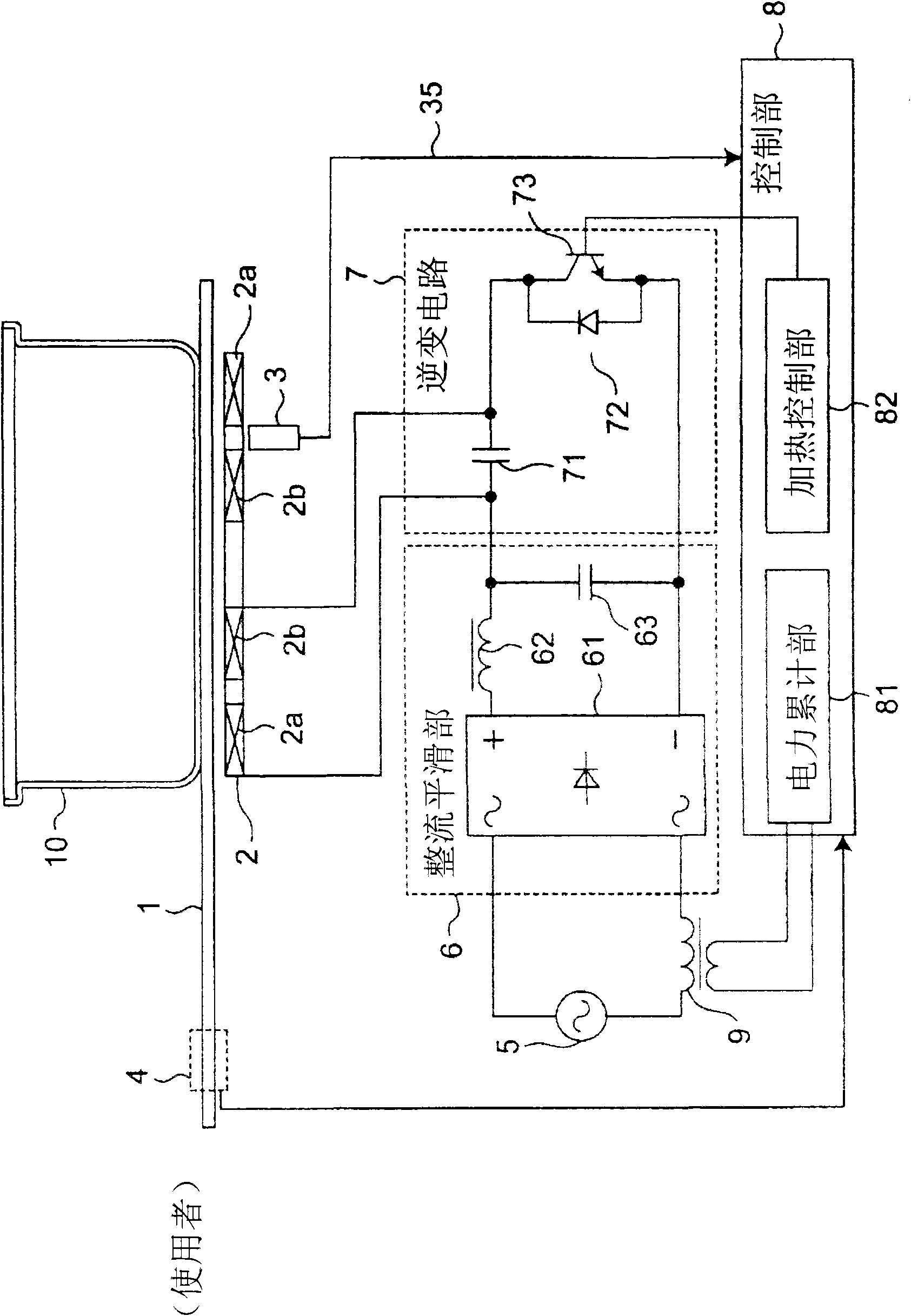

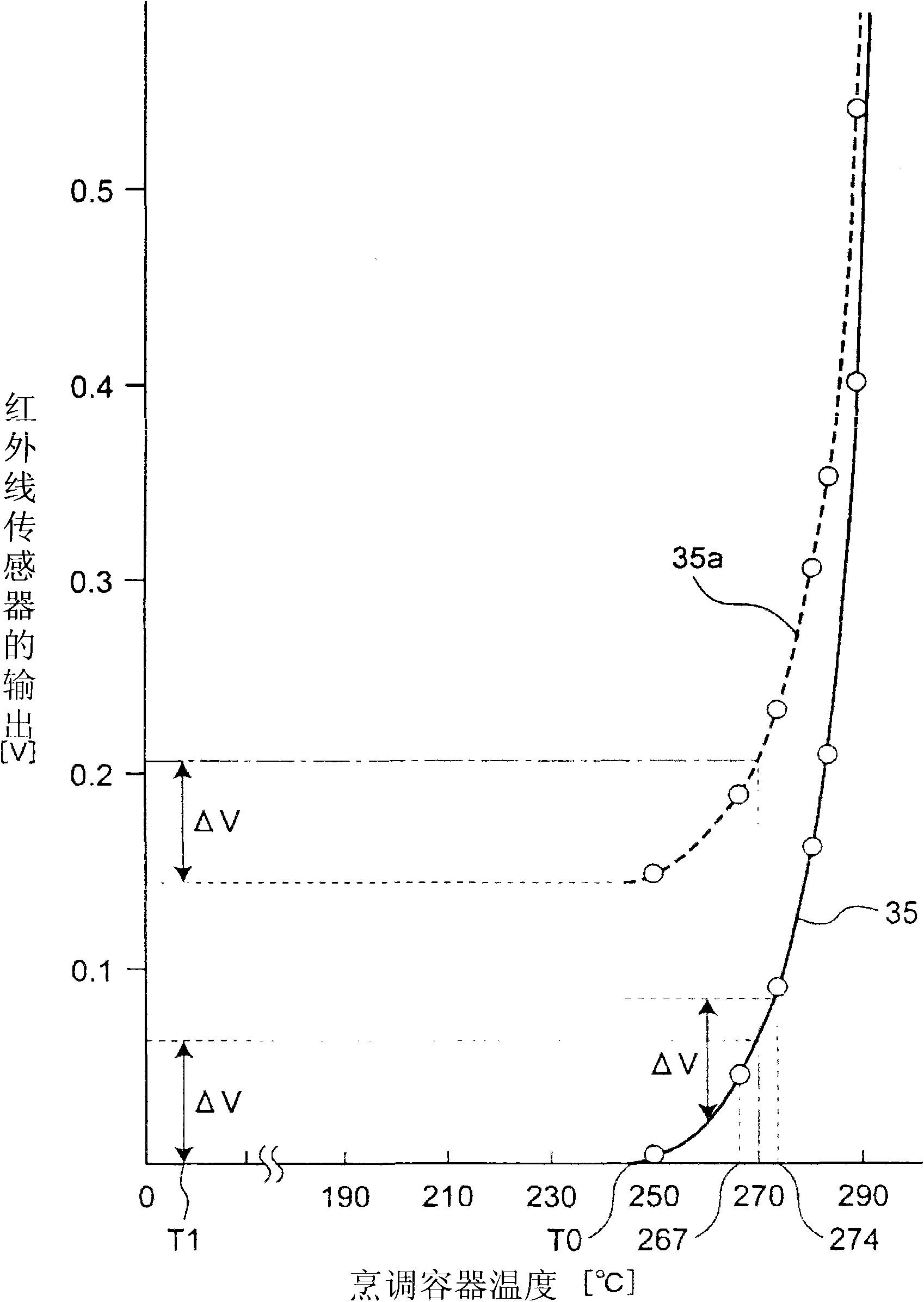

[0050] figure 1 The configuration of the induction heating cooker according to Embodiment 1 of the present invention is shown. The induction heating cooker of this embodiment has an infrared sensor 3, and heats a cooking vessel 10 such as a pan by controlling the heating electric power after the integrated value of the input electric power required for the temperature detected by the infrared sensor 3 to reach a predetermined value.

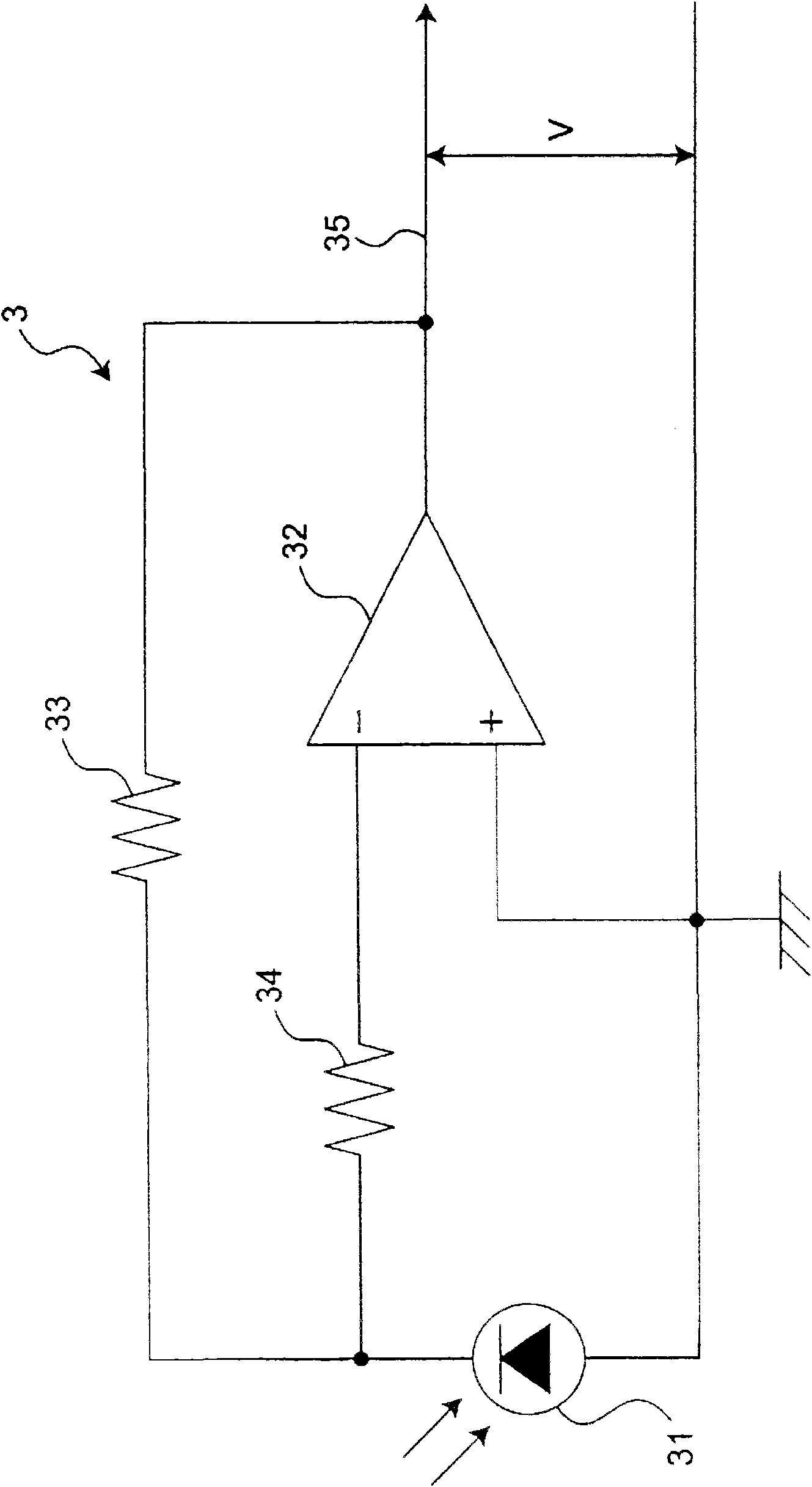

[0051] The induction heating cooker according to Embodiment 1 of the present invention includes a top plate 1 provided on the upper surface of the device, and a heating coil 2 for inductively heating a cooking container 10 on the top plate 1 by generating a high-frequency magnetic field. The top plate 1 is made of an electrical insulator such as glass, and transmits infrared rays. The heating coil 2 is arranged under the top plate 1 . The heating coil 2 is divided into two concentric circles t...

Embodiment approach 2

[0091] 2.1 Operation of induction heating cooker

[0092] In this embodiment, the control after the accumulated electric energy reaches the predetermined electric energy Wh1 or more ( Figure 4 The control after step 403) is different from Embodiment 1. In Embodiment 1, during the execution of the first heating control mode (S404) or the second heating control mode (S405), the heating control mode will not be switched to another heating control mode during the heating process, but will continue in the initially determined control mode. heating. However, in this embodiment, it is possible to switch between the first heating control mode and the second heating control mode during the heating process. The structure of the induction heating cooker of this embodiment is the same as that of Embodiment 1. As shown in FIG.

[0093] use Figure 9 ~ Figure 11 , operations different from those in Embodiment 1 will be described. Figure 9 The flow of the first heating control mode in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com