Hinge and production process thereof

A production process and hinge technology, applied in the direction of pinned hinges, door/window accessories, folding boards, etc., can solve the problems of loss of raw materials, high heat energy, high energy consumption, etc., to save production processes, simplify production processes, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

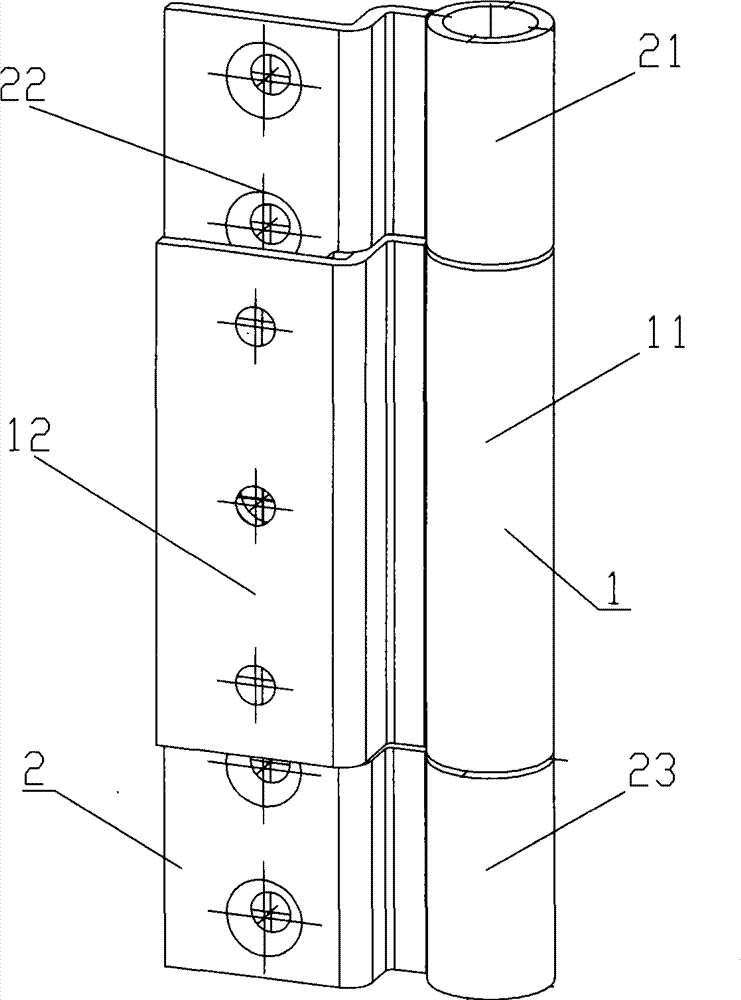

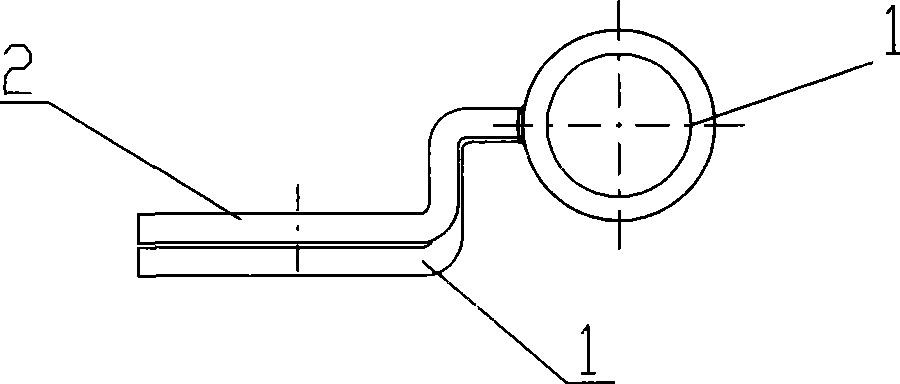

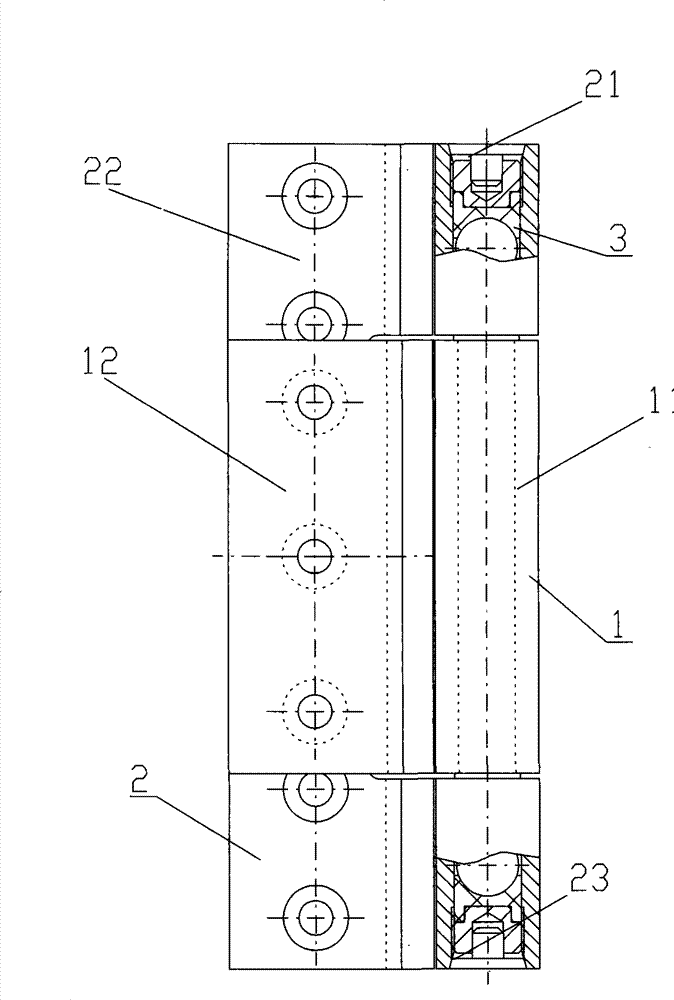

[0054] The invention discloses a hinge, such as figure 1 , 2 , 3, 4, include hinge part one and hinge part two, described hinge part one is hinge door frame part 2, hinge part two is hinge door leaf part 1; described hinge door frame part 2 and hinge door leaf part 1 all include There are hinge pieces and one or more hinge reels; wherein, at least one hinge reel and one piece of hinge pieces are connected by welding.

[0055]The hinged door frame part 2 includes one or more hinge reels one and one hinge piece one 22; the hinged door leaf part 1 includes one or more hinge reels two 11 and one hinge piece two 12; wherein, the The hinge reel 1 and the hinge piece 1 22 are connected as a whole by welding, or the hinge reel 11 and the hinge piece 12 are connected as a whole by welding; a connecting device connects the hinge door frame 2 and the hinge door leaf Part 1 is connected as a whole.

[0056] like figure 1 , 5 , 6, and 7, the hinge piece 22 of the hinge door frame part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com