Heating method of polyethylene fibre bundle

A polyethylene fiber and heating method technology, applied in the field of polyethylene fiber bundles, can solve problems affecting the normal production of polyethylene fiber bundles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

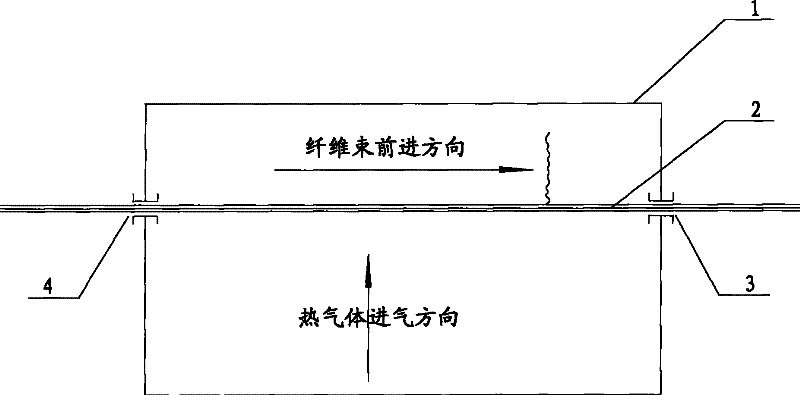

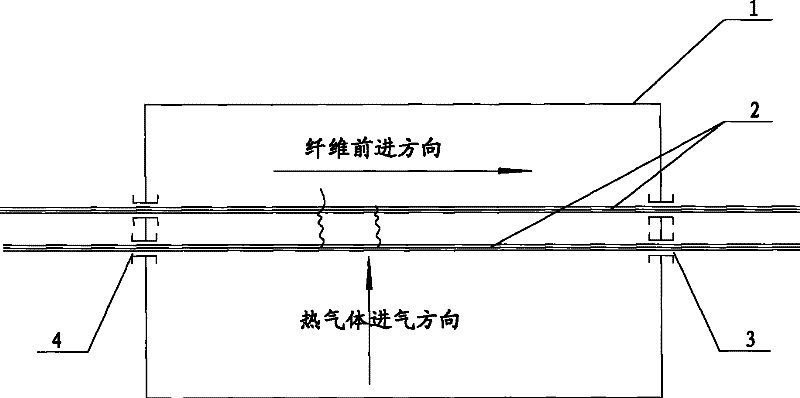

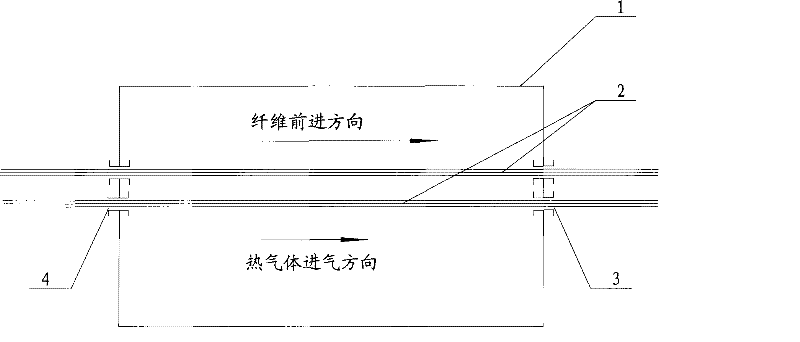

[0034] See image 3 , image 3 It is a schematic diagram of the polyethylene fiber bundle heating method in Example 1 of the present invention.

[0035] In the present invention, the ultra-high molecular weight polyethylene powder is swollen, sprayed, formed into jelly and initially drawn to form a polyethylene fiber bundle precursor. The polyethylene fiber bundle precursor refers to the polyethylene that has just become solid from the liquid state. Generally speaking, polyethylene needs a pre-drawing step after it has just formed a solid state. Usually, the polyethylene fiber after the pre-drawing step The bundle is called a strand.

[0036] In this embodiment, the polyethylene fiber bundle 2 passes through the polyethylene fiber bundle inlet 4 and the polyethylene fiber bundle outlet 3 of the heating box 1 from left to right, there is hot gas inside the heating box 1, and the hot gas can heat the polyethylene fiber bundle 2 for heating.

[0037]Install a nozzle near the ...

Embodiment 2

[0044] See Figure 4 , Figure 4 It is a schematic diagram of the polyethylene fiber bundle heating method in Example 2 of the present invention.

[0045] In this embodiment, the heating of the polyethylene fiber bundle 2 is completed in three heating boxes, respectively: the first heating box 5 , the second heating box 6 and the third heating box 7 . The structure of these three heating boxes is identical, and is similar to the heating box described in Example 1.

[0046] In the first heating box 5, the hot gas adopts hot air, and the temperature of the hot air is 70° C., and the advancing speed of the polyethylene fiber bundle 2 at the polyethylene fiber bundle inlet 4 is 2 m / min. The advancing speed at outlet 3 of the polyethylene fiber bundle of 5 was 2.3 m / min. The length of the box is 1.4 meters and the width is 70 centimeters.

[0047] In the second heating box 6, the hot gas adopts hot air, and the temperature of the hot air is 90° C., and the advancing speed of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com