Method for brewing wheat beer by using ungerminated wheat for matching with wheat malt

A technology of wheat beer and wheat malt, which is applied in the field of beer brewing, can solve the problems of low colloidal stability of beer and oxidative blackening of wort, etc., achieve the effect of reducing the content of condensable nitrogen, meeting the growth demand, and improving the clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

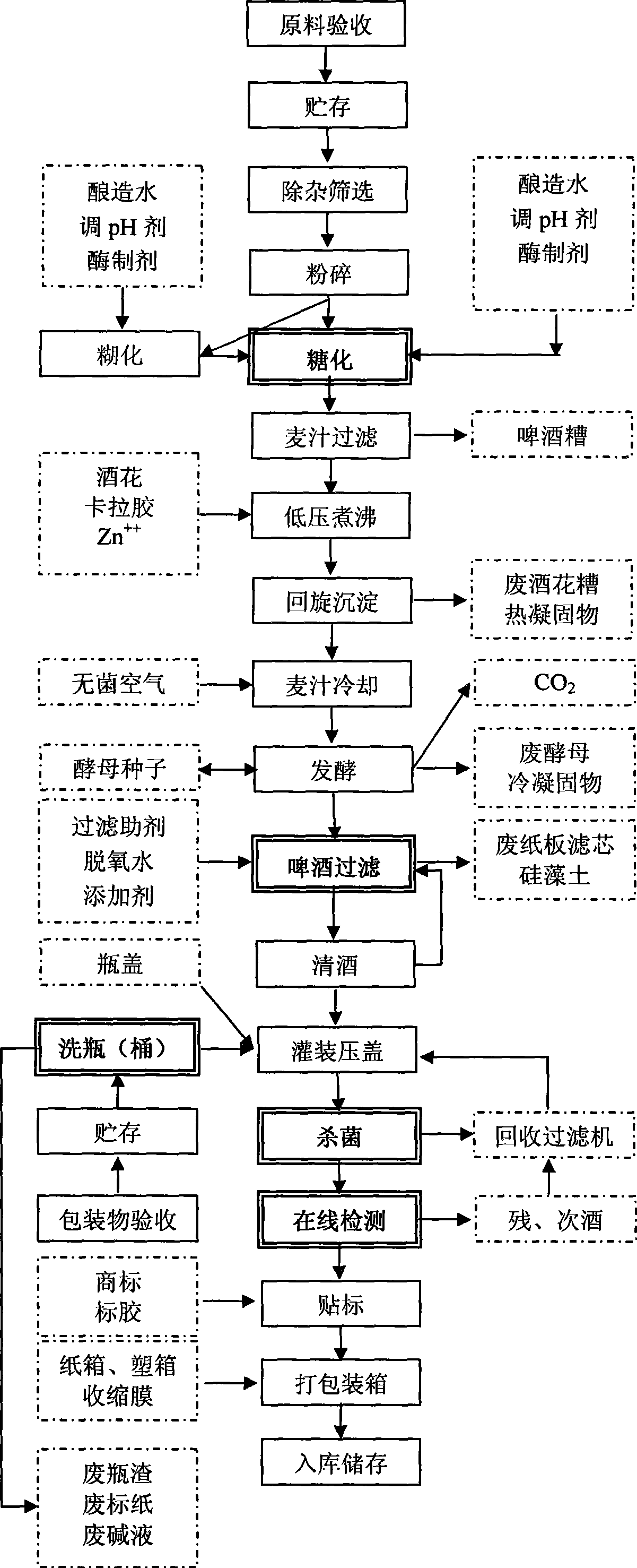

Image

Examples

Embodiment 1

[0012] (1) Raw material crushing: the material is crushed after removing impurities and screening, and the percentage by weight of each material component is: 35% of rice, 30% of wheat, and 35% of wheat germ;

[0013] (2) Gelatinization: add wheat flour and rice flour into the gelatinization pot together, add 3.8 tons of water per ton of raw materials, add high temperature resistant amylase 8u / g, protease 50u / g, pentosanase 0.2Kg / g into the gelatinization pot t, xylanase 0.25Kg / t, gypsum 180ppm, stir evenly, temperature control 52±0.5°C and keep warm for 55 minutes, heat up to 92±0.5°C at a heating rate of 1°C / min and keep warm for 15 minutes, at 1°C / min The heating rate is increased to 100 ° C for 20 minutes;

[0014] (3) Saccharification: After the wheat germ is crushed, put it into the mash pot, add 2.5 tons of water per ton of raw materials, add protease 50u / g, wheat compound enzyme 0.35Kg / t, gypsum 180ppm, and phosphoric acid to adjust the pH of the mixture to 5. 5. Keep...

Embodiment 2

[0021] (1) Raw material crushing: the material is crushed after removing impurities and screening, and the percentage by weight of each material component is: 30% of rice, 35% of wheat, and 35% of wheat germ;

[0022] (2) Gelatinization: add wheat flour and rice flour into the gelatinization pot, add 4.0 tons of water per ton of raw materials, add high temperature resistant amylase 10u / g, protease 25u / g, pentosanase 0.22Kg / g in the gelatinization pot t, xylanase 0.22Kg / t, gypsum 200ppm, stir evenly, temperature control 56±0.5°C and keep warm for 48 minutes, heat up to 90±0.5°C at a heating rate of 1°C / min and keep warm for 20 minutes, at 1°C / min The heating rate is raised to 100 ° C for 15 minutes;

[0023] (3) Saccharification: After the wheat germ is crushed, put it into the mash pot, add 2.7 tons of water per ton of raw materials, add protease 60u / g, wheat compound enzyme 0.40Kg / t, gypsum 200ppm, and phosphoric acid to adjust the pH of the mixed liquid to the mash pot. 5~5...

Embodiment 3

[0030] (1) Raw material pulverization: the material is pulverized after removing impurities and screening, and the percentage by weight of each material component is: 40% of rice, 30% of wheat, and 30% of wheat germ;

[0031] (2) Gelatinization: add wheat flour and rice flour into the gelatinization pot, add 3.8 tons of water per ton of raw materials, add high temperature resistant amylase 8.5u / g, protease 30u / g, pentosanase 0.24Kg into the gelatinization pot / t, xylanase 0.24Kg / t, gypsum 190ppm, stir evenly, keep temperature at 55±0.5°C for 52 minutes, raise the temperature to 92±0.5°C at a heating rate of 1°C / min and keep warm for 18 minutes, then heat at 1°C / min The heating rate of min is raised to 100°C for 17 minutes;

[0032] (3) Saccharification: after the wheat germ is crushed, add it to the mash pot, add 2.6 tons of water per ton of raw materials, add protease 80u / g, wheat compound enzyme 0.37Kg / t, gypsum 190ppm, and phosphoric acid to adjust the pH of the mixture to 5....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com