Functionalized polypropylene for flexible packages, preparation method thereof and functionalized polypropylene used for preparing flexible packages by the method

A polypropylene, flexible packaging technology, applied in the directions of packaging, wrapping paper, transportation and packaging to achieve the effect of ensuring uniformity, preventing degradation and long irradiation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In another specific embodiment of the present invention, a method for preparing functionalized polypropylene for flexible packaging is provided, comprising:

[0056] Step a: irradiating the polypropylene powder under nitrogen protection, the radiation source used is a cobalt source, the radiation dose is 20-60 kGy, and the dose rate is 2-0.5 kGy / h;

[0057] Step b: placing the polypropylene powder irradiated in step a for 6 to 48 hours;

[0058] as well as

[0059] Step c: Carry out melt grafting modification of the irradiated polypropylene powder and the non-irradiated polypropylene powder after being placed in step b with graft monomers of polar comonomers, wherein optional Adding antioxidants and / or lubricants,

[0060] Wherein, the irradiated polypropylene powder is 30-70 parts by weight, the non-irradiated polypropylene powder is 30-70 parts by weight, and the polar comonomer is 0.4-15 parts by weight.

[0061] In a preferred embodiment, the polar comonomer for ...

Embodiment 1

[0069] Preparation of Example 1 Functionalized Polypropylene Sample

[0070] Step 1: Put the polypropylene (PP) powder (Tianjin Petrochemical Company No. 2 Petrochemical Plant, brand TC-1) in a sealed plastic barrel, and use high-purity nitrogen to purify it for 1 hour at a flow rate of 100 L / min. Remove the oxygen in the material, and then store it tightly.

[0071] Step 2: The above-mentioned deoxidized PP powder is irradiated with gamma rays at a dose rate of 1.0kGy / hour under nitrogen protection, the radiation source used is a cobalt source, and the (total) radiation dose is 40kGy, wherein (total) Radiation dose = dose rate × radiation time.

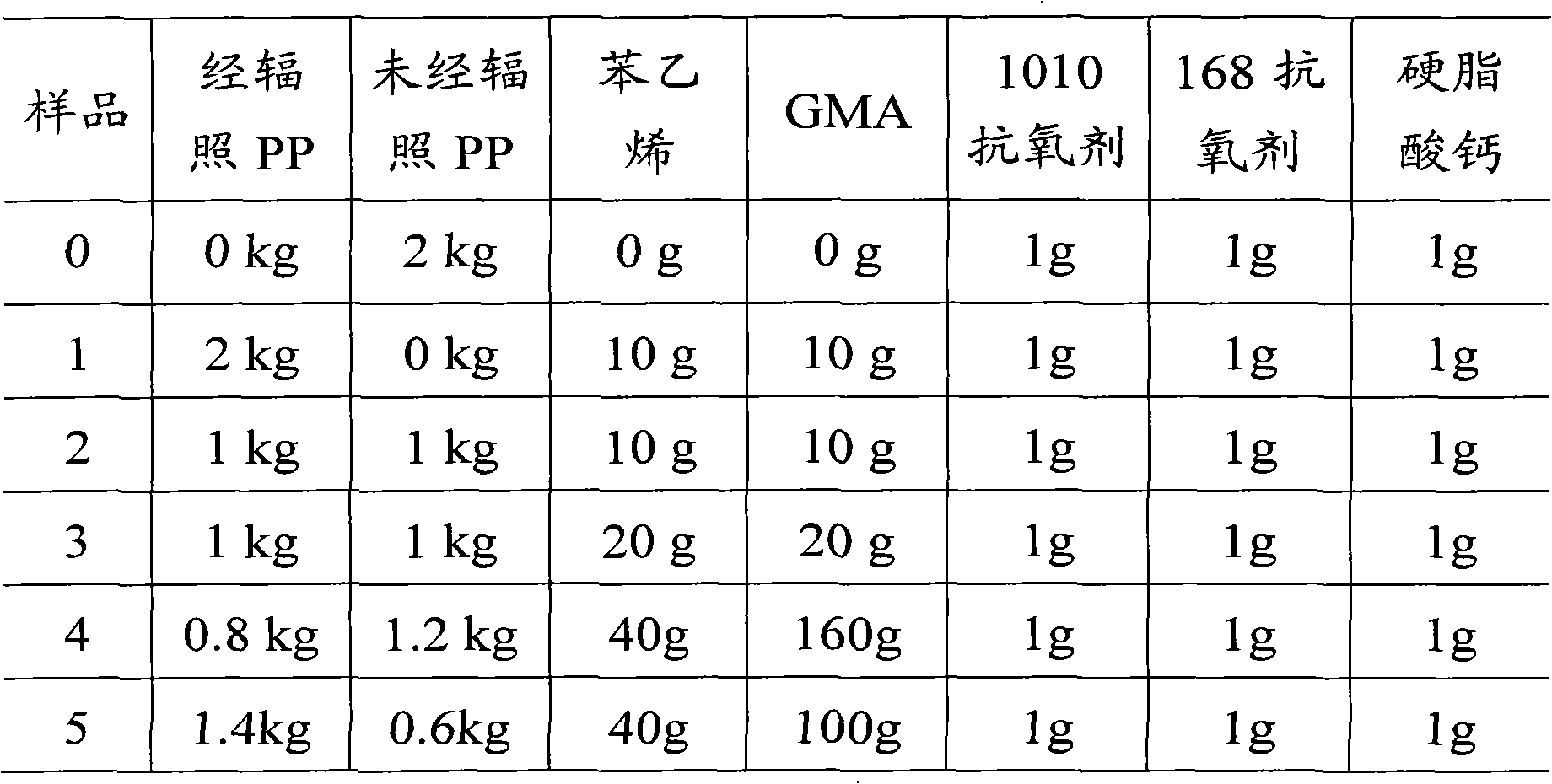

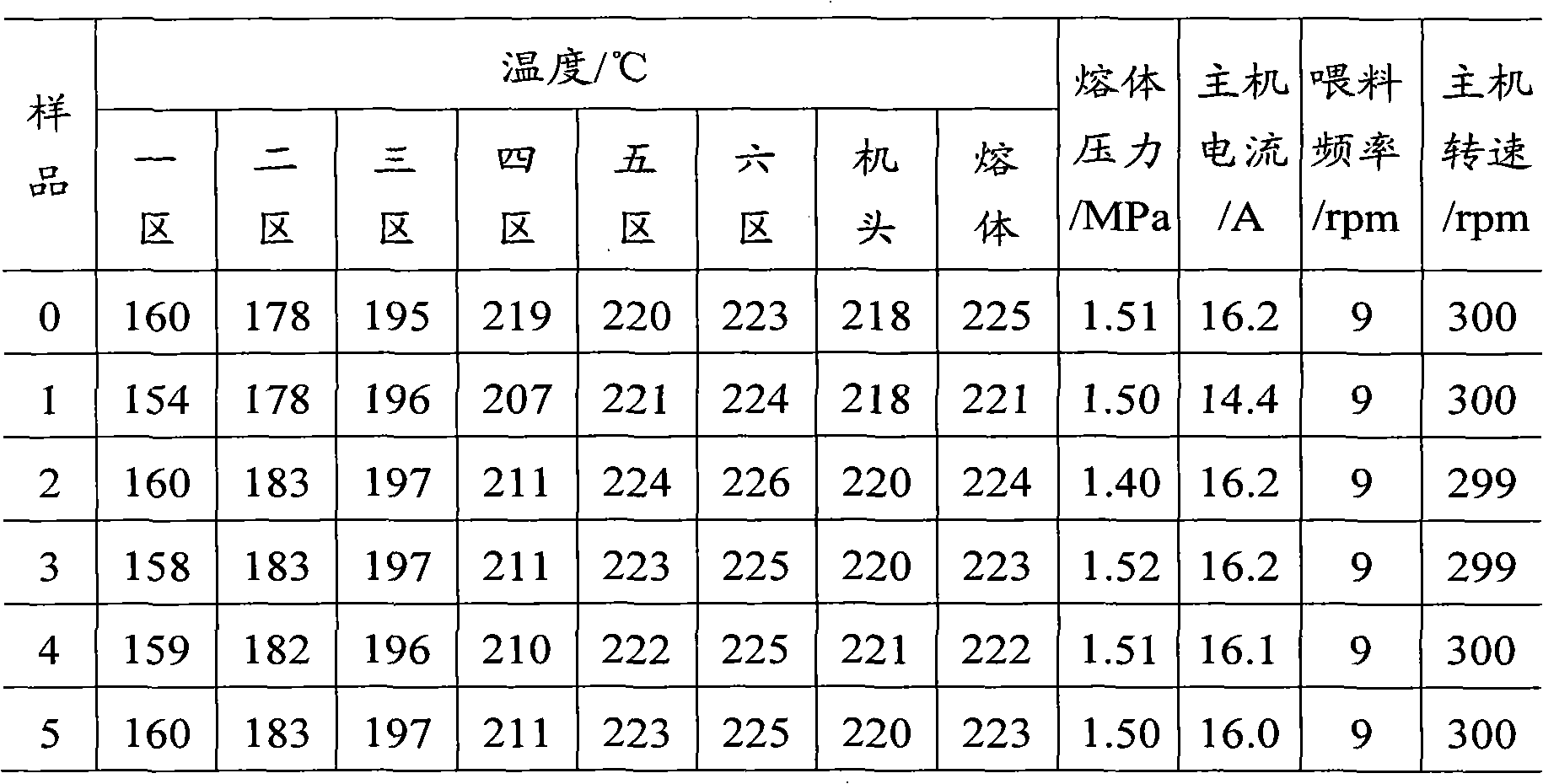

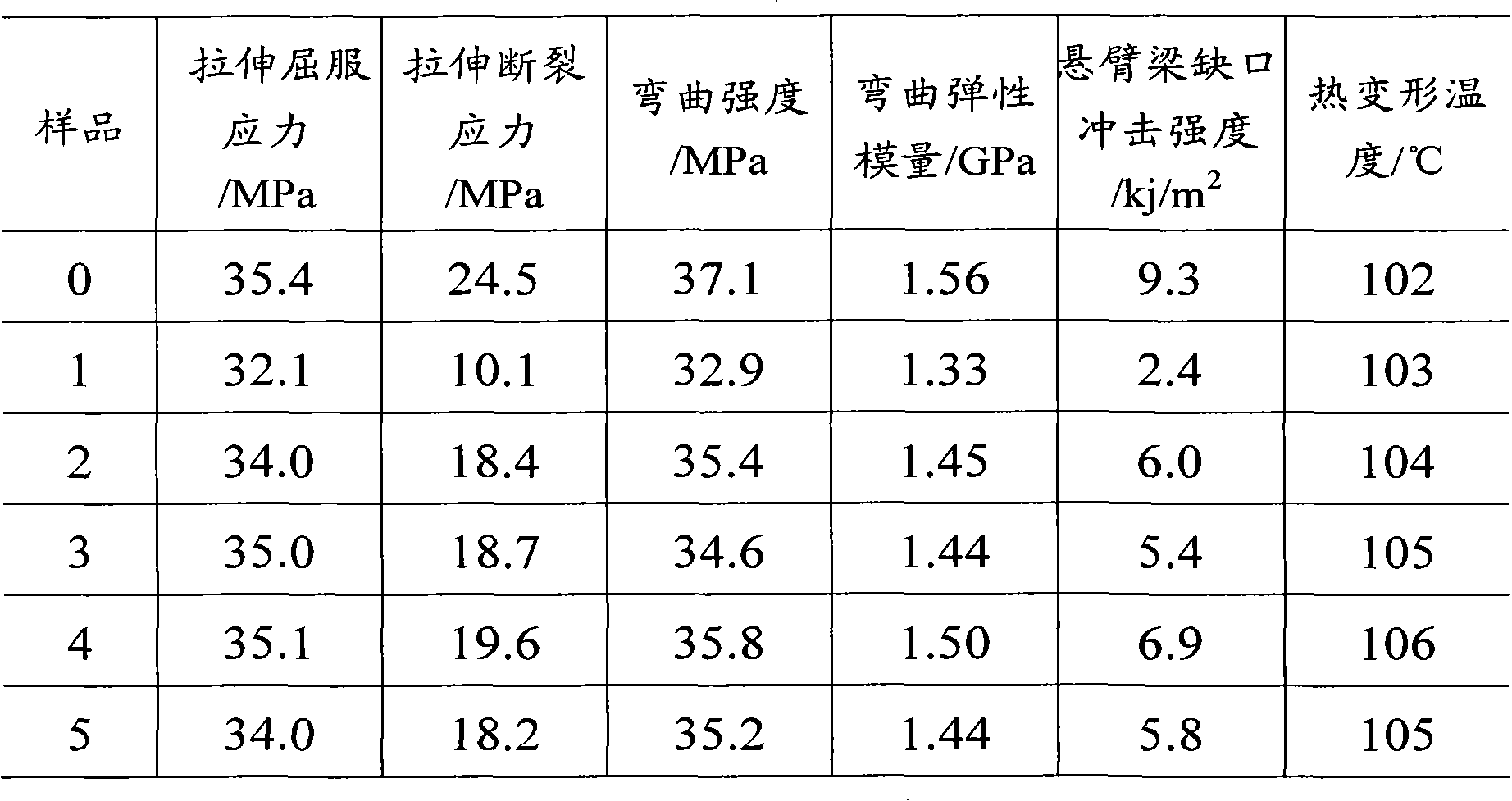

[0072] Step 3: After placing the irradiated PP powder for 24 hours, under the protection of nitrogen, mix it with other antioxidants, lubricants, polar monomers (glycidyl methacrylate, hereinafter in accordance with the ratio in Table 1) GMA), co-monomer (styrene) blended for 3 to 10 minutes.

[0073] Table 1 Ratio of raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com