Process for the preparation of tetronic acid

A technology of tetronic acid and alkoxyacetoacetic acid, which is applied in the field of preparation of tetronic acid, can solve the problems of cost and difficulty in industrial scale, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

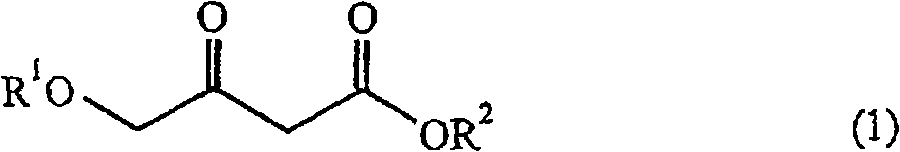

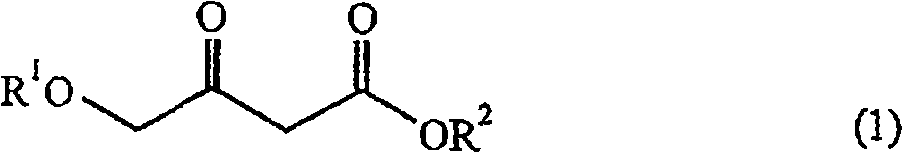

Image

Examples

Embodiment 1

[0073] Sodium tert-butoxide (53.7 g, 0.559 mol) was suspended in tetrahydrofuran (429 g), and a mixed solution of ethyl 4-chloroacetoacetate (40.0 g, 0.243 mol) and tetrahydrofuran (71.0 g) was added dropwise thereto and The temperature was made to be in the range of 20 to 30°C, and after completion of the dropwise addition, it was stirred at room temperature (25°C) for 20 hours. After concentrating tetrahydrofuran, an aqueous hydrochloric acid solution (a mixture of 34.4 g of 35% hydrochloric acid and 200 g of water) was added dropwise under ice cooling, followed by extraction with ethyl acetate and liquid separation. The organic layer was washed with water and then concentrated to obtain ethyl 4-tert-butoxyacetoacetate (yield 43.1 g, weight yield 87.7%, purity 76.6%).

[0074] Ethyl 4-tert-butoxyacetoacetate 1 H-NMR spectrum (CDCl 3 ): δ1.21(s, 9H), 1.27(t, 3H), 3.55(s, 2H), 4.01(s, 2H), 4.19(q, 2H)

[0075] The obtained ethyl 4-tert-butoxyacetoacetate (40 g, 0.152 mol (i...

Embodiment 2

[0077] The same method as in Example 1 was used to obtain ethyl 4-tert-butoxyacetoacetate.

[0078] The obtained ethyl 4-tert-butoxyacetoacetate (10 g, 0.0399 mol (in terms of purity)) was dissolved in acetic acid (21.1 g), and hydrogen chloride gas (0.0867 mol) was blown in at a temperature of 20 to 30°C. After blowing in, it stirred at room temperature (25 degreeC) for 1 hour. The reaction liquid was decompressed with a rotary evaporator, the residual hydrogen chloride gas was degassed, and the low boiling point substances and acetic acid were distilled off, and concentrated until the residual acetic acid amount was 1 / 2 (10.55 g) of the added amount. The residue was stirred to precipitate crystals, ethyl acetate (9 g) was added dropwise thereto, and the mixture was stirred at room temperature (25° C.) for 2 hours. Then, the crystal was taken out by filtration to obtain tetronic acid (yield 1.92g, yield 47.5%, purity 99.2%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com