Structure taking part of metal grid as grid medium etching blocking layer with high dielectric constant and integration method

A technology for etching barrier layers and high dielectric constants, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as damage to high-K gate dielectric materials, simplify integration complexity, and overcome Fermi The effect of the energy level pinning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

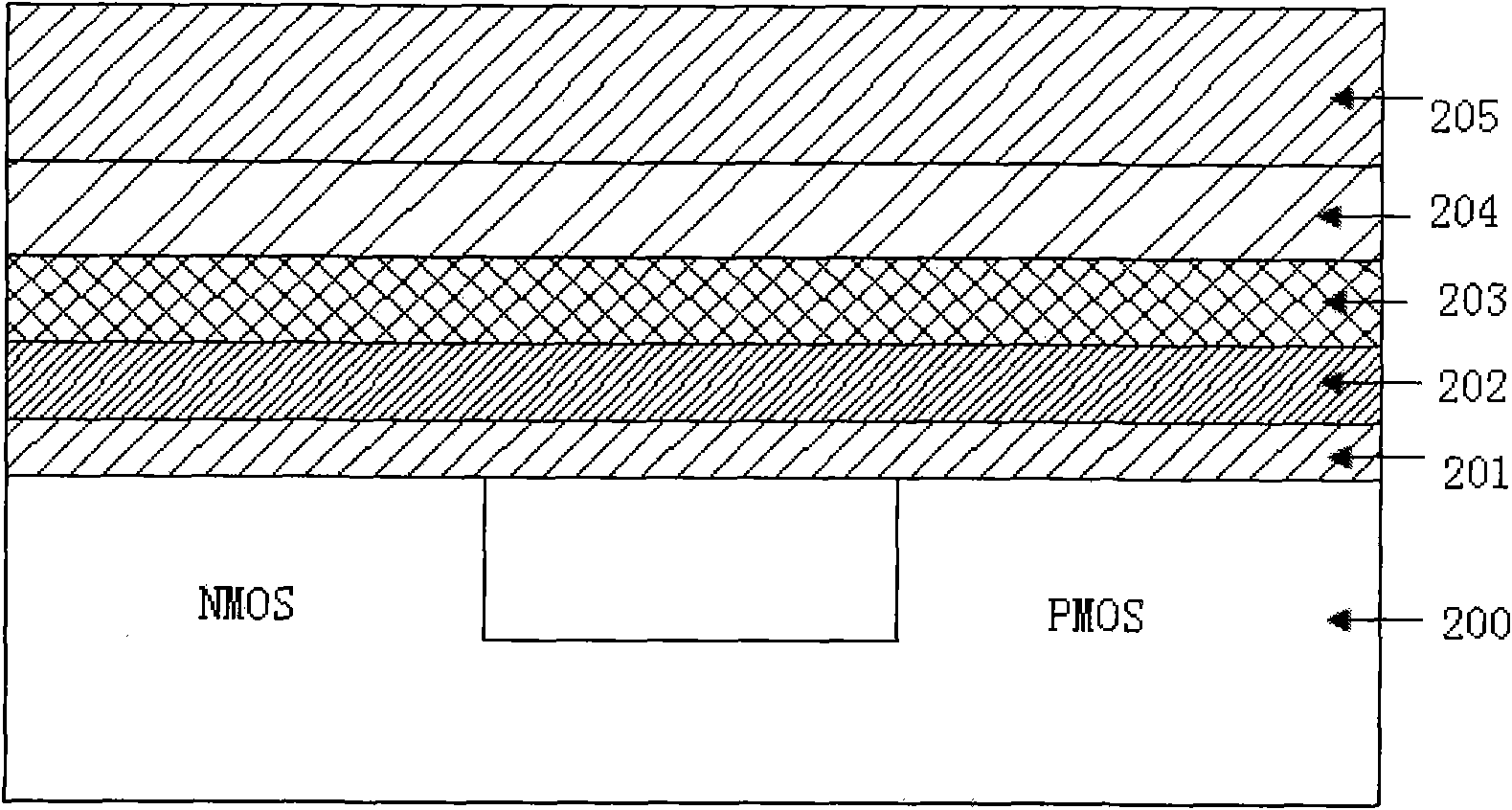

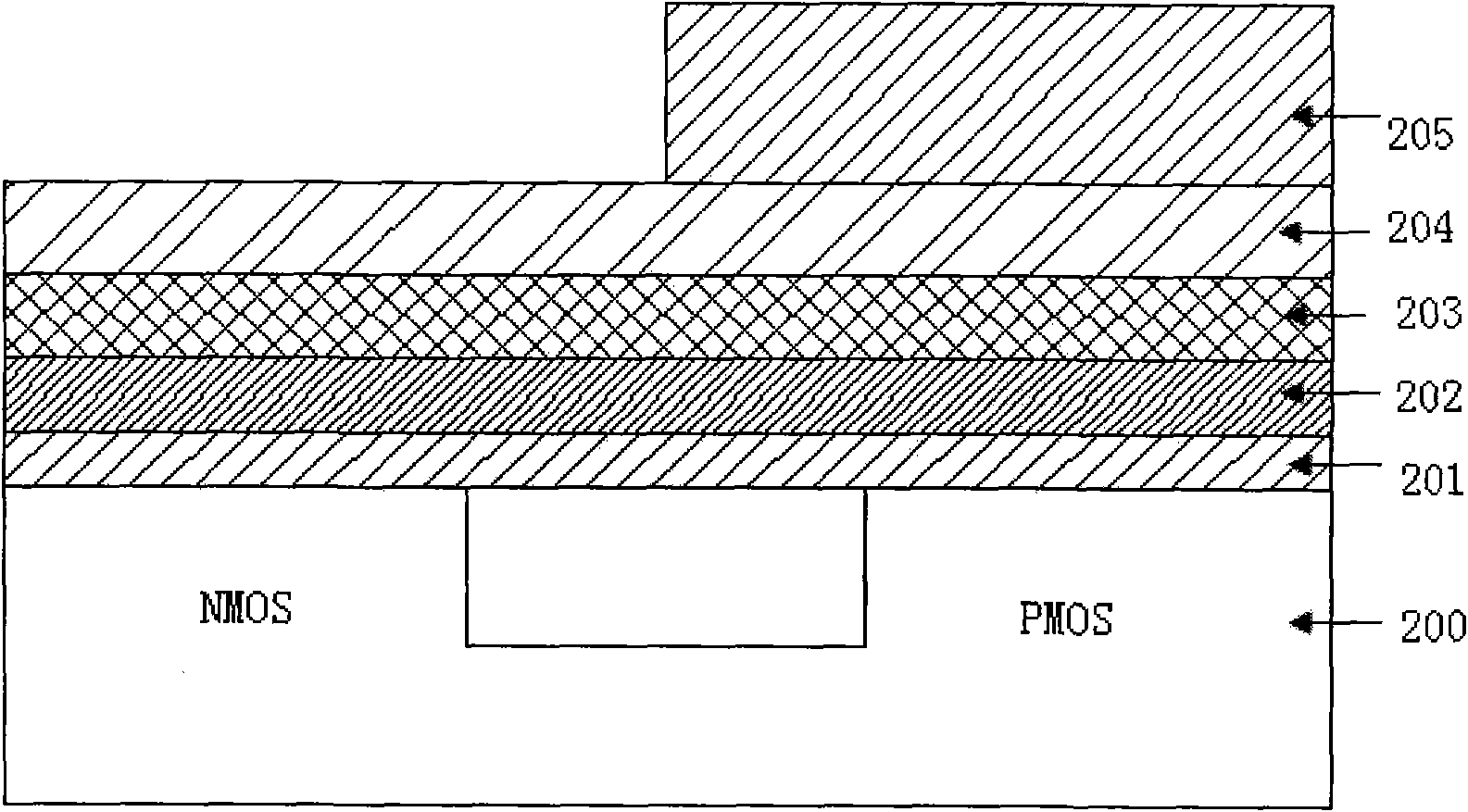

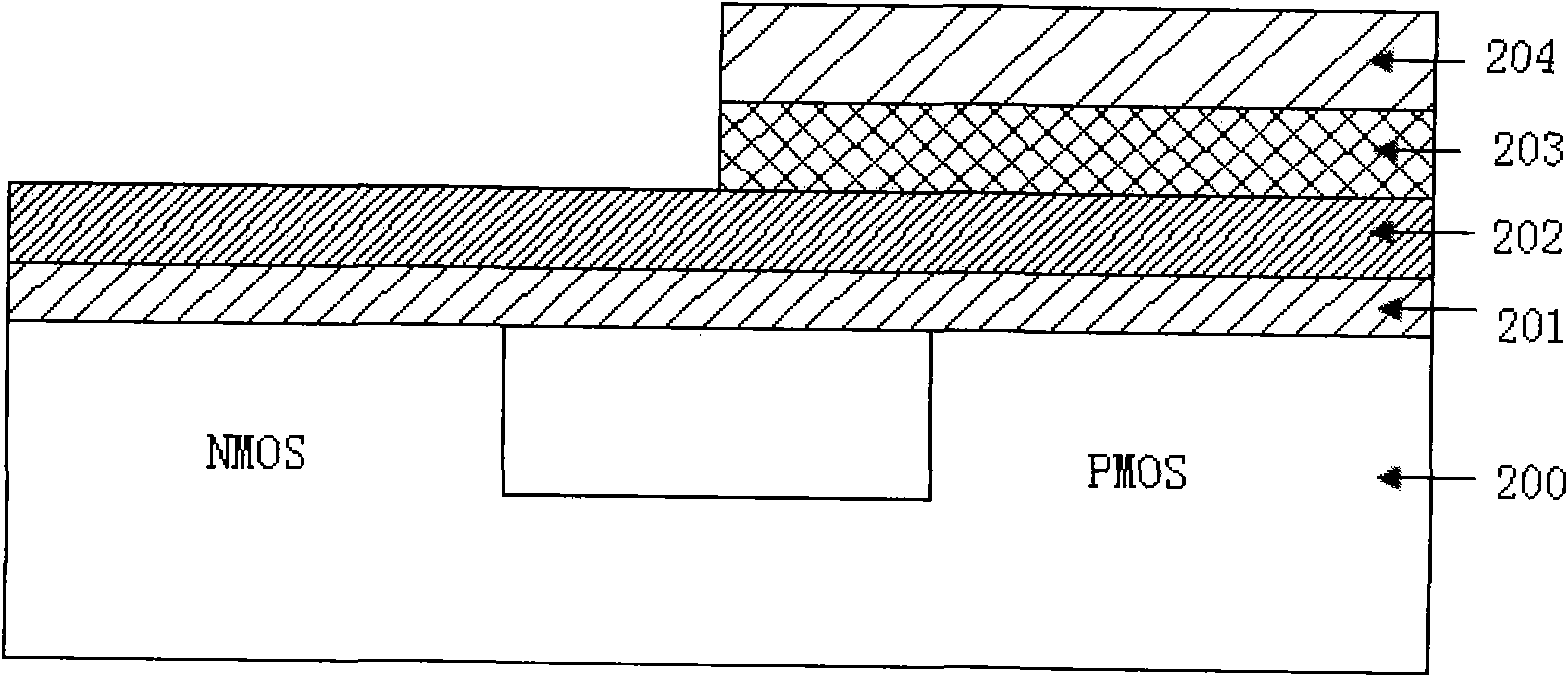

[0028] Step 1: Please refer to figure 1 , provide a silicon substrate 200 that has completed the shallow trench isolation (STI) process, and sequentially form a layer of film 201, a layer of film 202, a layer of film 203, a layer of film 204 and a layer of film 200 on the silicon substrate 200 Film 205. Thin film 201 is SiO 2 , with a thickness in the range of 1 to 5 nm. The thin film 202 and the thin film 203 are high-k dielectric layers, and the thin film 202 is HfSiO. Thin film 203 is Al 2 o 3 , the thin film 204 is TiN or WN, its thickness is in the range of 1 to 10 nanometers, and it is an etching barrier layer. The thin film 205 is a photoresist layer, and the thickness of the photoresist is in the range of 0.3 to 2 microns. After the thin film 202 and the thin film 203 are formed, an annealing treatment is required before the thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com