Joint lifting method used by rotor spinning frame for single-spindle roller feeding

A technology of rotor spinning machine and feeding roller, applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve the problems affecting the quality technical indicators of high-quality medium and fine yarn , to achieve the effect of improving the quality of the piecing, alleviating the loss and damage, and improving the yarn performance of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below.

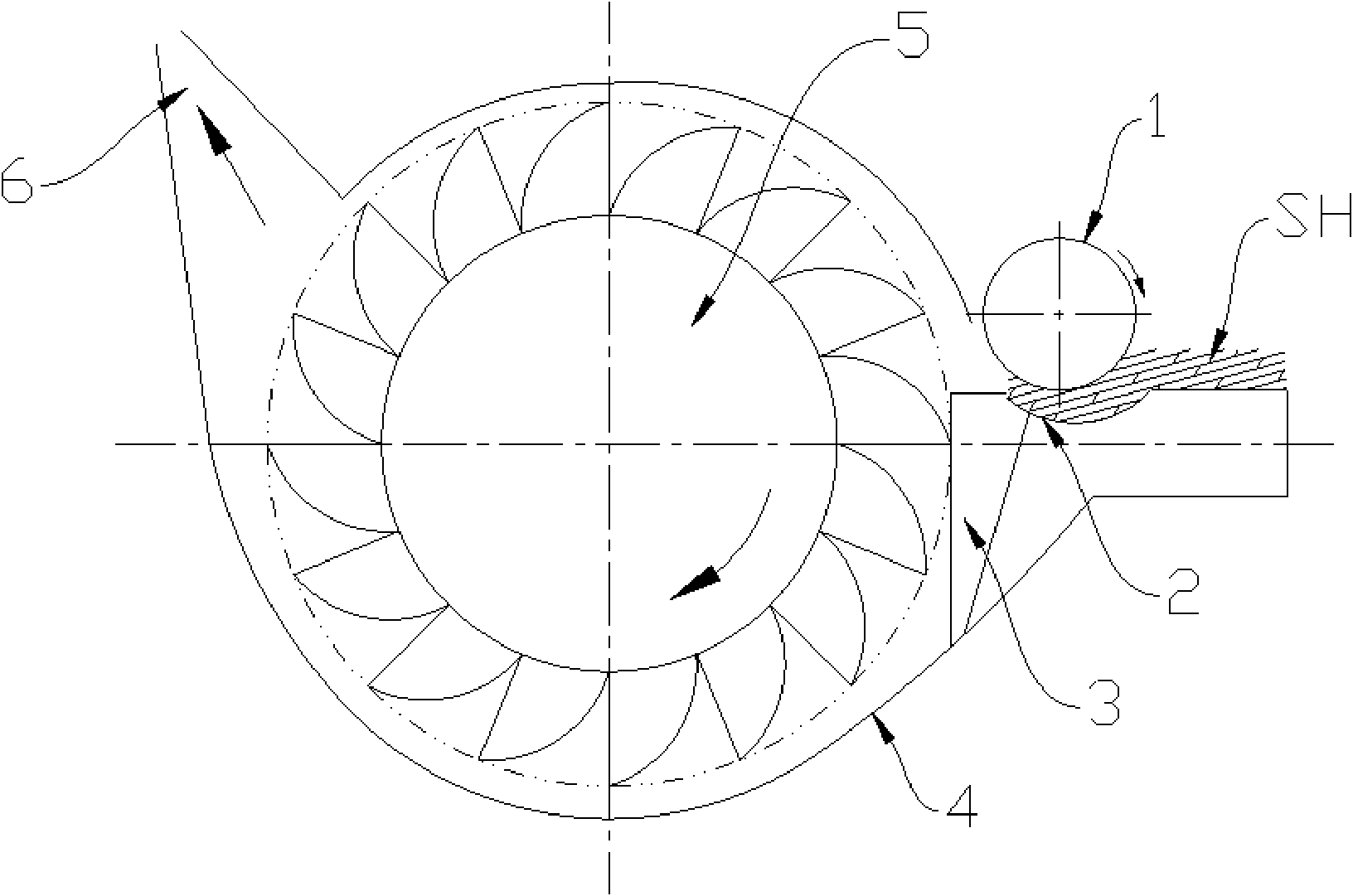

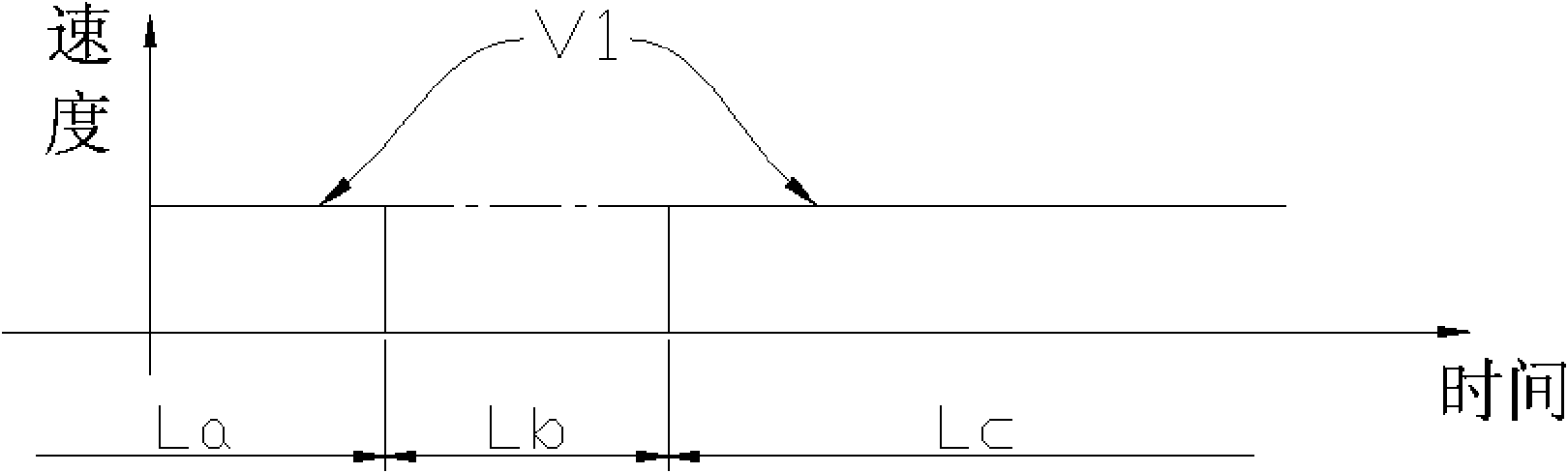

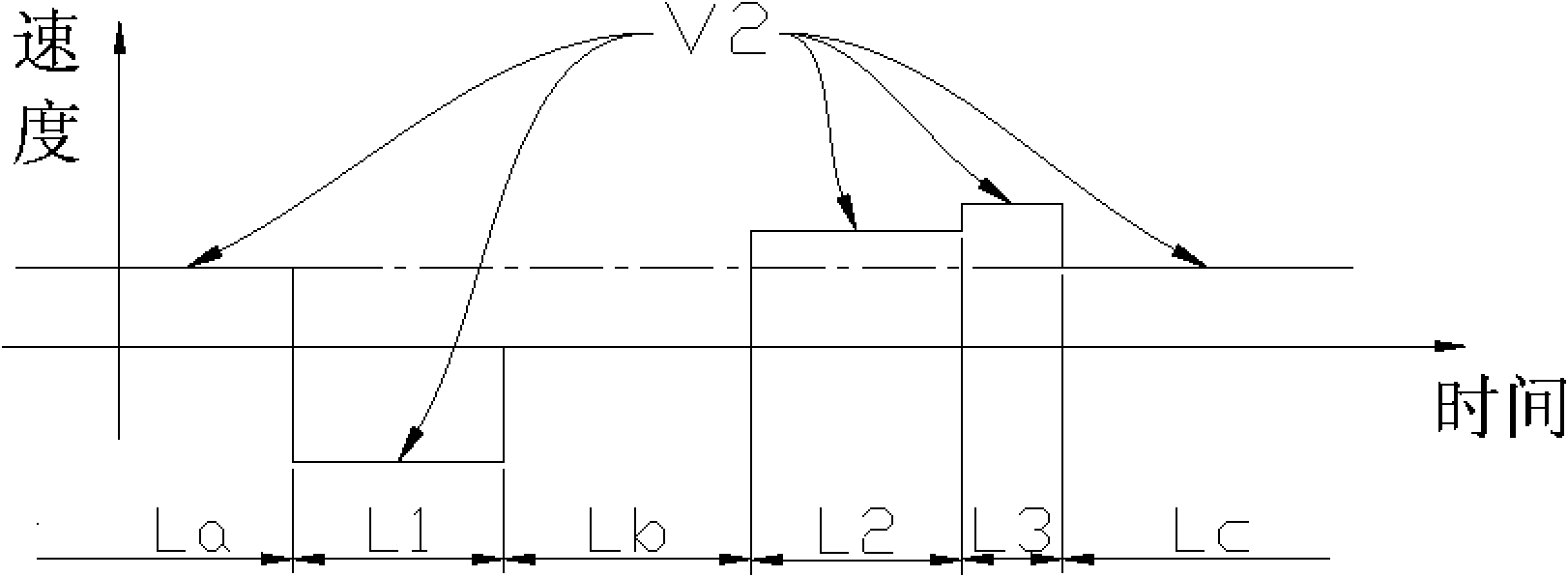

[0030] The biggest feature of the semi-automatic piecing of the rotor spinning machine is to complete the two main actions of fiber sliver feeding and yarn drawing without changing the speed of the rotor and carding roller. From the normal spinning process, we can know that only combining the twisting in the piecing process with the "rotor combined twisting" process in normal spinning is the goal of pursuing high-quality piecing. This requires the controlled feeding system to first complete the control of the amount of fibers participating in the combined twisting of the rotor, and also to control the control of the amount of fibers in the subsequent transmission, which is the transition from the joint position to normal spinning after the final yarn drawing. Provides a continuous rated guarantee of fiber flow.

[0031] High-quality joints can be distinguished from the shape and strength of the joints. The shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com