Extraction technology of glutamic acid recovered by combining crystal transformation and ion exchange

A technology of ion exchange and extraction technology, applied in the field of food industry, can solve the problems of reducing environmental protection pressure, high production cost and high consumption, and achieve the effects of eliminating pollution, improving crystal purity and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

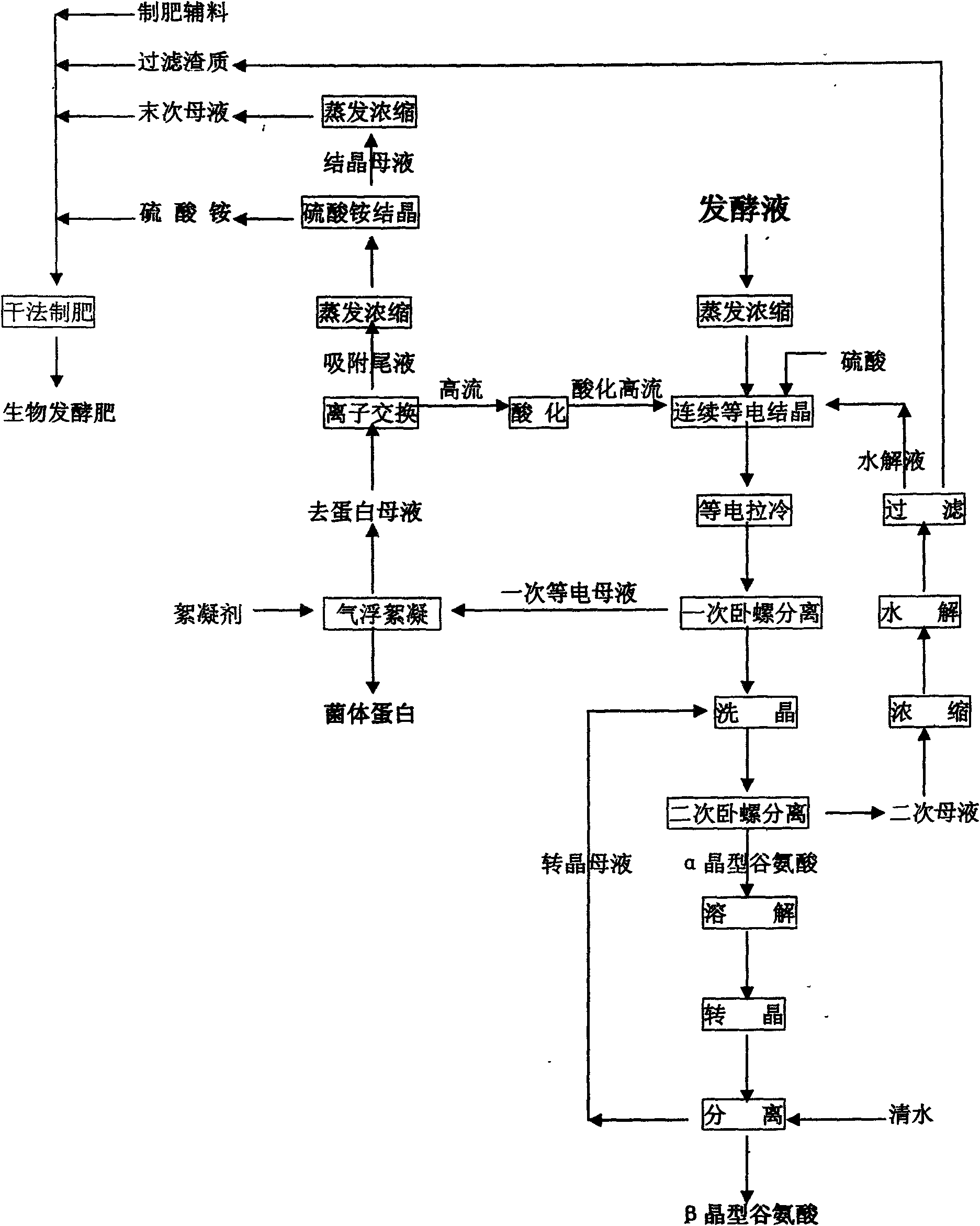

[0030] The glutamic acid extraction process of the present invention combined with ion exchange recovery adopts the following process steps:

[0031] The fermented liquid of the present invention is a glutamic acid-containing liquid obtained by fermenting starchy raw materials or molasses raw materials.

[0032] 1000ml glutamic acid fermentation broth, glutamic acid concentration is 10.8%, pH value: 6.7. Concentrate in a vacuum evaporator first to reduce the volume of the fermentation broth. The evaporation operation adopts single-effect concentration: the evaporation pressure is: -0.09MPa, the temperature is: 52°C, the concentration factor is about 3 times, and the volume of the concentrated liquid is: 350ml; slowly add the hydrolyzate to the concentrated liquid while stirring, Make the final pH value: 3.1, and cool down to 8°C to precipitate glutamic acid in the α crystal form; after the isoelectric crystallization is completed, pour the liquid into a three-legged centrifug...

Embodiment 2

[0035] The glutamic acid extraction process of the present invention combined with ion exchange recovery adopts the following process steps:

[0036] Take 80m 3 Glutamic acid fermentation broth, glutamic acid concentration: 11.5%, temperature 37°C, pH value: 6.5. Send it to the four-effect evaporator system for concentration. The concentration conditions are: first-effect heater pressure: 0.09MPa, temperature: 85°C, second-effect heater pressure: -0.04MPa, temperature: 75°C, third-effect heater Pressure: -0.08MPa, temperature: 65°C, fourth-effect heater pressure: -0.094MPa, temperature: 50°C, concentration times 2.5 times, concentrate volume 32m 3 ; Enter the continuous isoelectric crystallization section, add sulfuric acid and the hydrolyzate obtained from the previous batch operation and acidify the high flow, adjust the pH step by step, and gradually lower the temperature at the same time, the pH gradient measured by test paper is: 4.2 ~ 3.2, and the temperature step is: 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com