Precise ceramic workbench with quartz base

A technology of precision ceramics and worktables, applied in manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of product yield impact, low efficiency, cost increase, etc., to achieve the best work efficiency and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

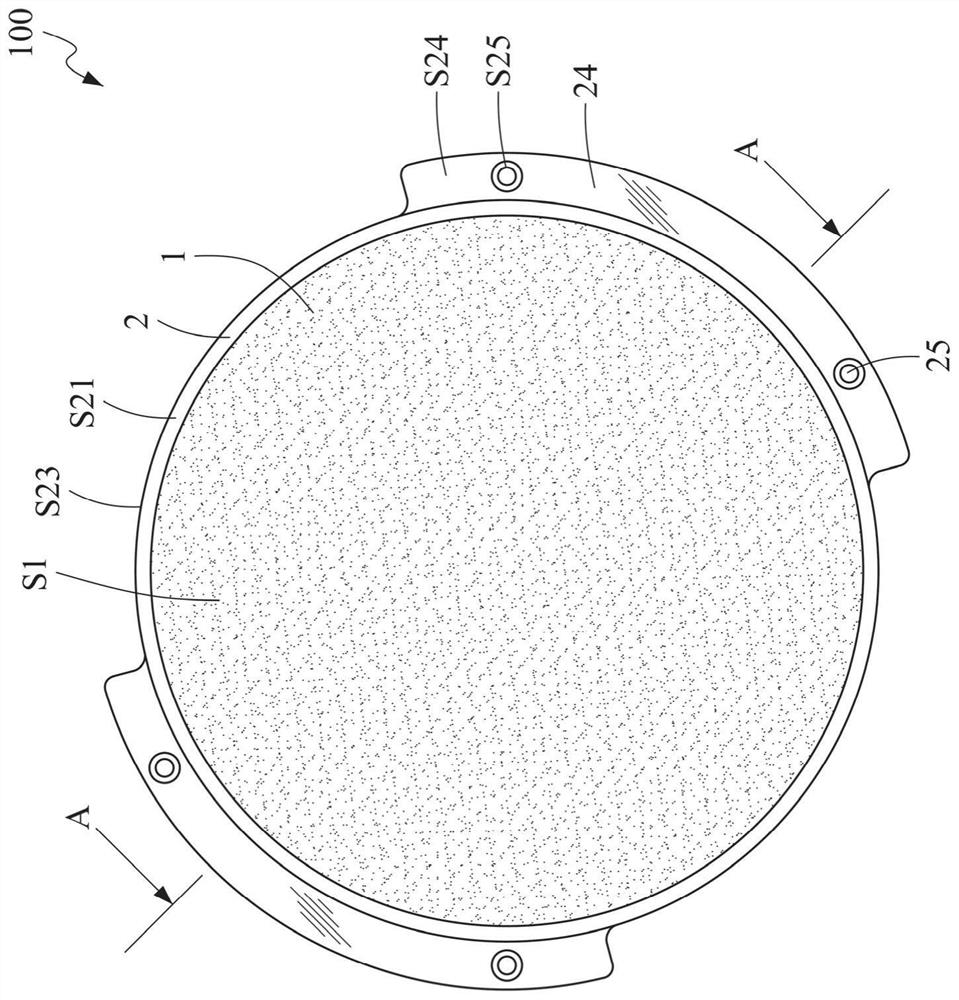

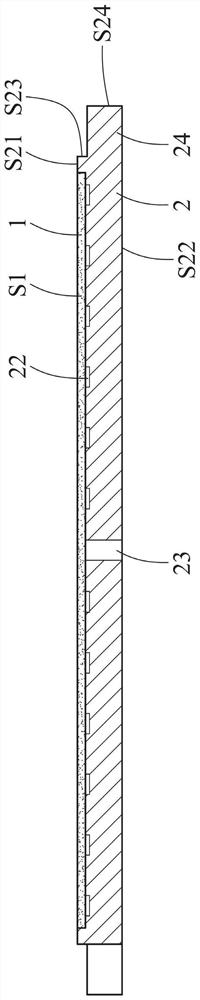

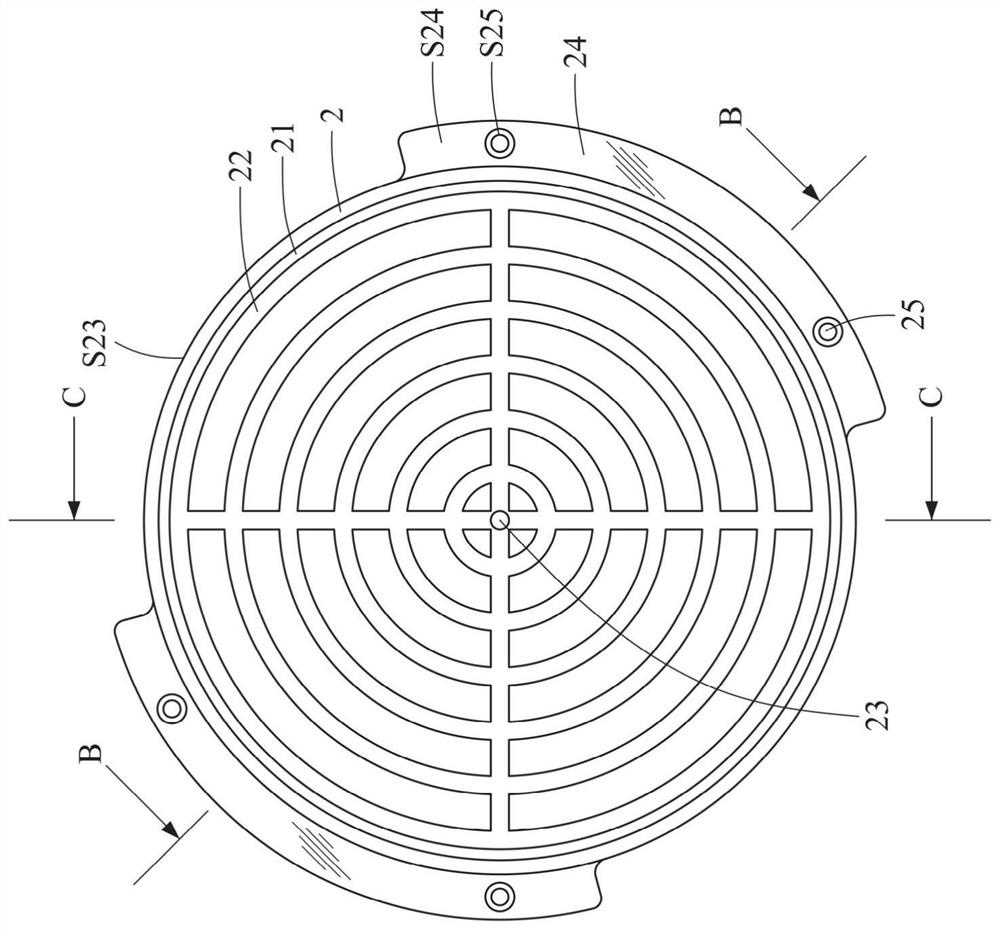

[0032] based on the following Figure 1 to Figure 5 , and the embodiment of the present invention will be described. This description is not intended to limit the embodiment of the present invention, but is one of examples of the present invention.

[0033] Such as figure 1 As shown, the size of the precision ceramic table 100 with a quartz base according to an embodiment of the present invention is suitable for an eight-inch wafer. In other embodiments, the precision ceramic workbench 100 has other larger or smaller sizes to match the wafers to be processed.

[0034] Wherein, the precision ceramic workbench 100 includes: a multi-hole precision ceramic disc 1 and a quartz base 2 .

[0035] Specifically, as figure 1 As shown, the multi-hole precision ceramic disc 1 is a porous material and has several through holes, and each through hole penetrates between the upper surface S1 and the lower surface of the multi-hole precision ceramic disc. The upper surface S1 of the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com