Preparation method of high purity dicyclopentadiene

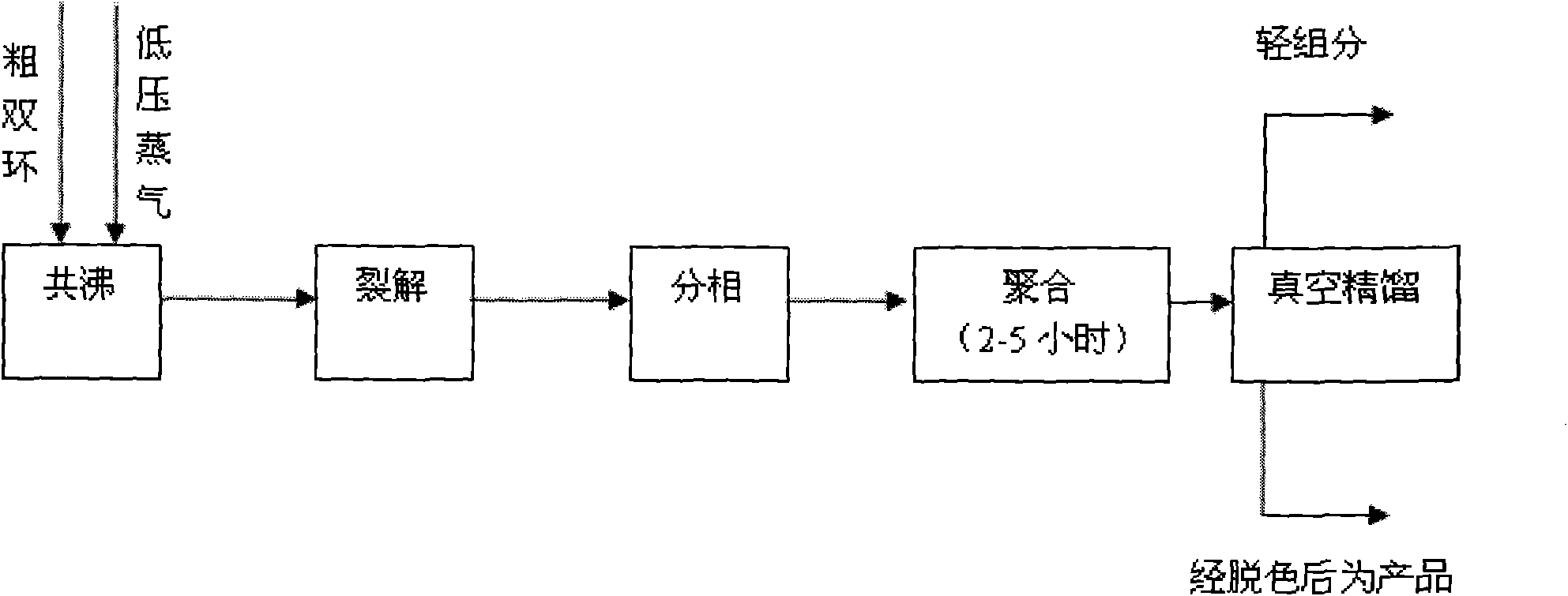

A technology for dicyclopentadiene and cyclopentadiene is applied in the field of preparation of high-purity dicyclopentadiene, which can solve the problems of complex process, multiple reactors, large equipment investment, etc., and achieves low production cost and high purification accuracy. , the effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The C5 distillate raw material enters the azeotropic tank and contacts with the low-pressure steam in countercurrent to make it vaporized. The operating pressure is 30KPa, the operating temperature is 105°C, and the liquid level is 40% of the height of the tank. The gasified product from the azeotropic tank enters The cracking reactor is cracked, the feed temperature is 240°C, the outlet temperature is 337°C, and the operating pressure is 30KPa. The cracked product is sent to the phase separation tank together with the water vapor as diluent to separate cyclopentadiene, and cyclopentadiene enters Polymerization is carried out in the dimerization reactor, and the product is crude dicyclopentadiene. The feed temperature of the dimerization reactor is 18°C, the outlet temperature is 35°C, the operating pressure is 480KPa, and the polymerization time is 2 hours. Dicyclopentadiene is sent to the rectification tower for vacuum distillation, wherein the temperature at the top o...

Embodiment 2

[0027] The C5 distillate raw material enters the azeotropic tank and contacts with the low-pressure steam in countercurrent to make it vaporized. The operating pressure is 35KPa, the operating temperature is 110°C, and the liquid level is 50% of the tank height. The cracking reactor is cracked, the feed temperature is 250°C, the outlet temperature is 340°C, and the operating pressure is 35KPa. The cracked product is sent to the phase separation tank together with the water vapor as diluent to separate cyclopentadiene, and cyclopentadiene enters Polymerization is carried out in the dimerization reactor, and the product is crude dicyclopentadiene. The feed temperature of the dimerization reactor is 20°C, the outlet temperature is 45°C, the operating pressure is 500KPa, and the polymerization time is 3.5 hours. Dicyclopentadiene is sent to the rectification tower for vacuum distillation, wherein the temperature at the top of the tower is 7°C, the temperature of the tower bottom is...

Embodiment 3

[0029] The C5 distillate raw material enters the azeotropic tank and contacts with the low-pressure steam in countercurrent to make it vaporized. The operating pressure is 40KPa, the operating temperature is 115°C, and the liquid level is 60% of the height of the tank. The cracking reactor is cracked, the feed temperature is 260°C, the outlet temperature is 342°C, and the operating pressure is 40KPa. The cracked product is sent to the phase separation tank together with the water vapor as diluent to separate cyclopentadiene, and cyclopentadiene enters Polymerization is carried out in the dimerization reactor, and the product is crude dicyclopentadiene. The feed temperature of the dimerization reactor is 23°C, the outlet temperature is 60°C, the operating pressure is 530KPa, and the polymerization time is 5 hours. Dicyclopentadiene is sent to the rectification tower for vacuum distillation, wherein the temperature at the top of the tower is 8°C, the temperature of the tower bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com