Numerical control piston inner diameter processor

A technology in processing machines and pistons, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, poor processing accuracy, low precision, etc., to improve processing accuracy, high processing efficiency, The effect of convenient operation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

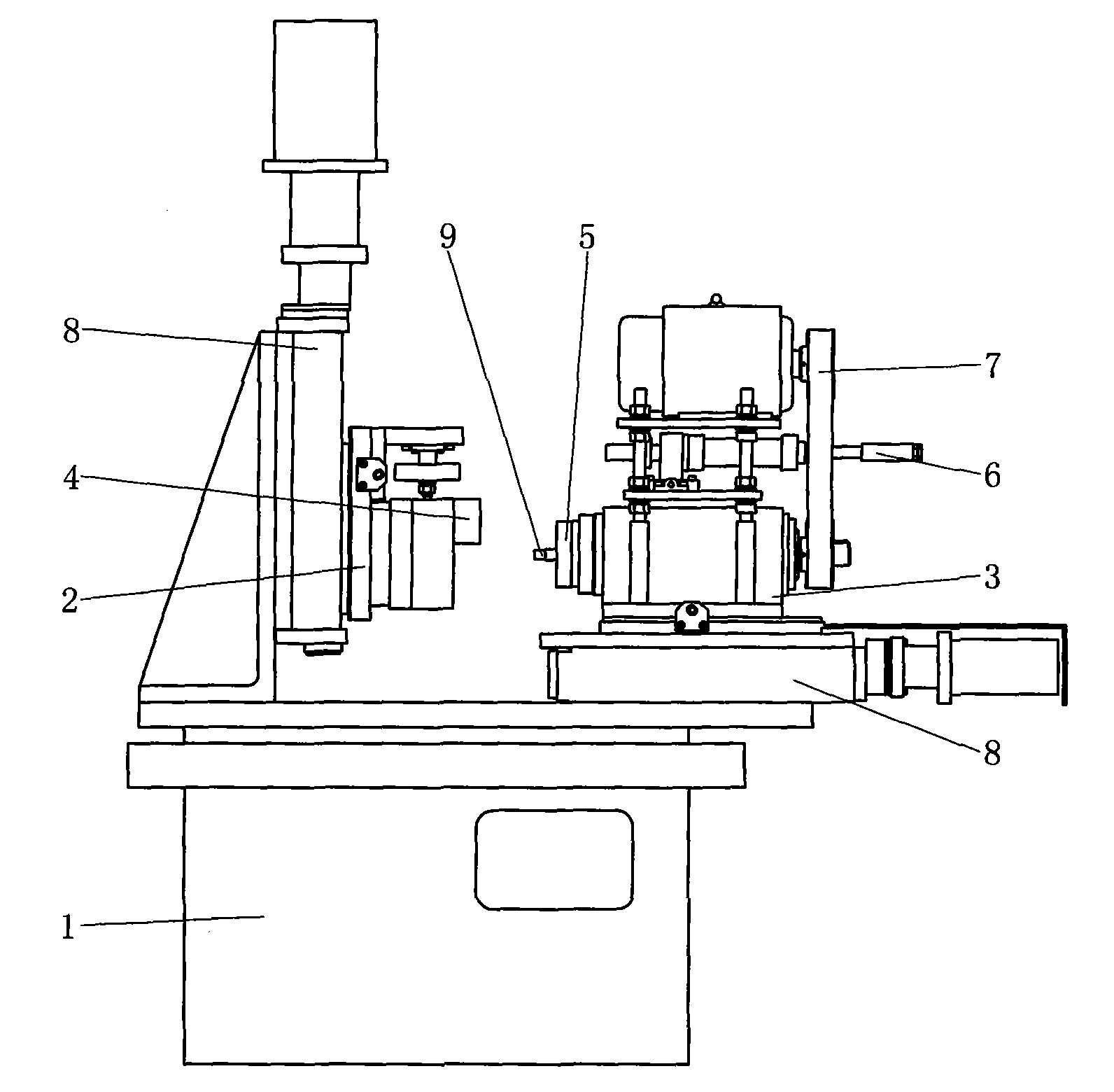

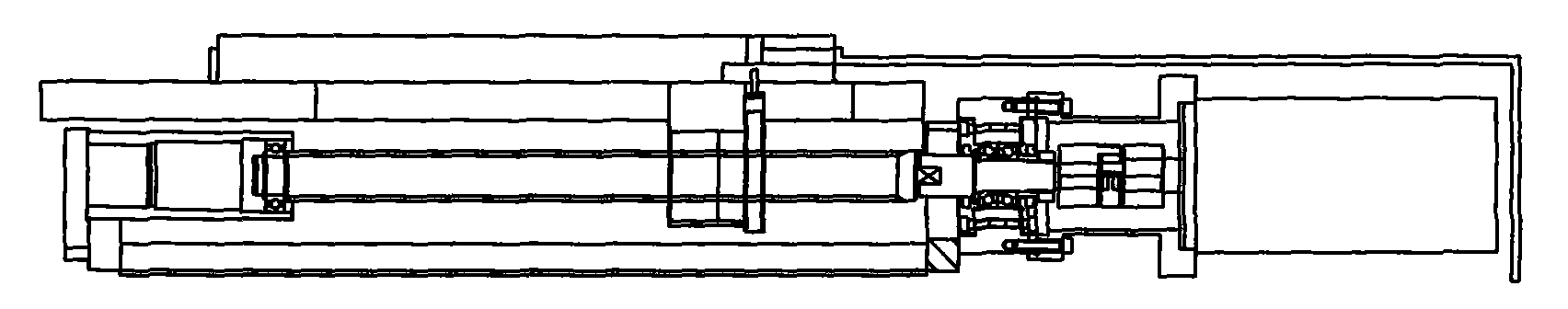

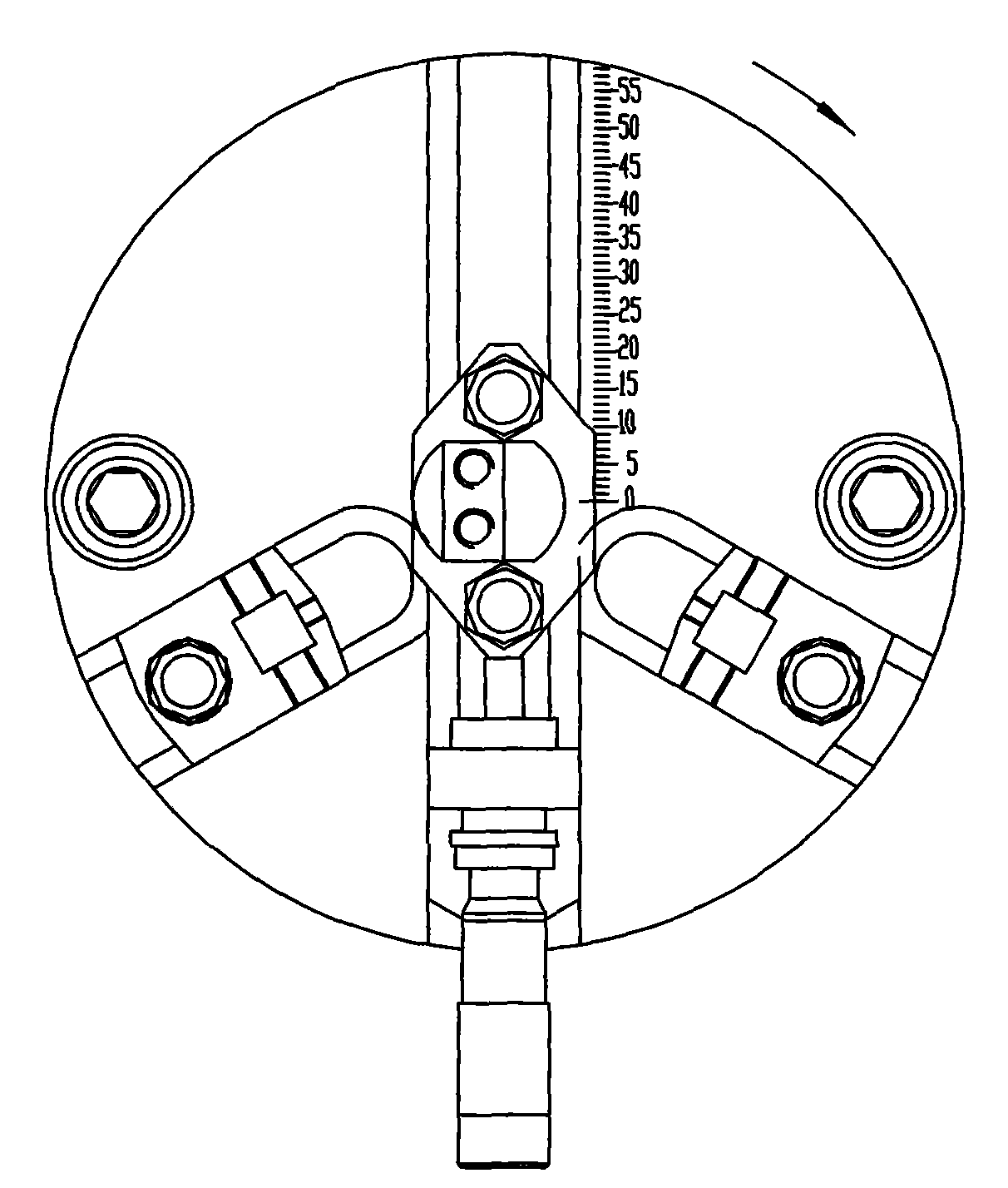

[0012] refer to figure 1 , 2 Or as shown in 3, the present invention comprises machine body 1, fixed main shaft 2, rotating main shaft 3 and feed mechanism 8, and fixed main shaft 2 and rotating main shaft 3 are arranged on the feeding mechanism 8, and the feeding mechanism 8 of fixed main shaft 2 moves longitudinally Connected on the machine body 1, the fixed spindle 2 is provided with a piston workpiece fixture 4. The piston workpiece fixture 4 can be a three-jaw chuck clamping mechanism, and the three-jaw chuck clamping mechanism is clamped by a rotating cylinder through a rotating gear pair. The feed mechanism 8 of the rotary spindle 3 is connected to the machine body 1 by lateral movement, and the rotary spindle 3 is provided with a tool fixing structure 5 and a pneumatic preload mechanism 6, and is also connected with a power transmission mechanism 7, which is driven by the power transmission mechanism 7 to drive The rotary spindle 3 rotates and drives the feed mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com