Planet rolling intermediate winding drum of wire drawing machine

A wire drawing machine and planetary technology, applied in the field of wire drawing production equipment in the wire rod product industry, can solve the problems of lack of reverse tension drawing, high equipment cost, affecting the quality of finished products, etc., to simplify operation and maintenance, reduce equipment cost, and prevent steel wire The effect of pulling white and pulling

Inactive Publication Date: 2010-03-17

严国语

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to meet this requirement, the linear and loop-type wire drawing machines must be equipped with a very complicated electrical control system and speed regulating mechanism. The operation must have a considerable technical level, and the maintenance is not easy to master. At the same time, the equipment cost is too high

[0003] The pulley type continuous wire drawing machine has the advantages of simple structure, less investment, convenient operation, and simple management, etc., but the steel wire is prone to axial torsion during the drawing process, which affects the quality of the drawn product, and is not suitable for drawing high-strength steel wire. With the function of anti-pull pulling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

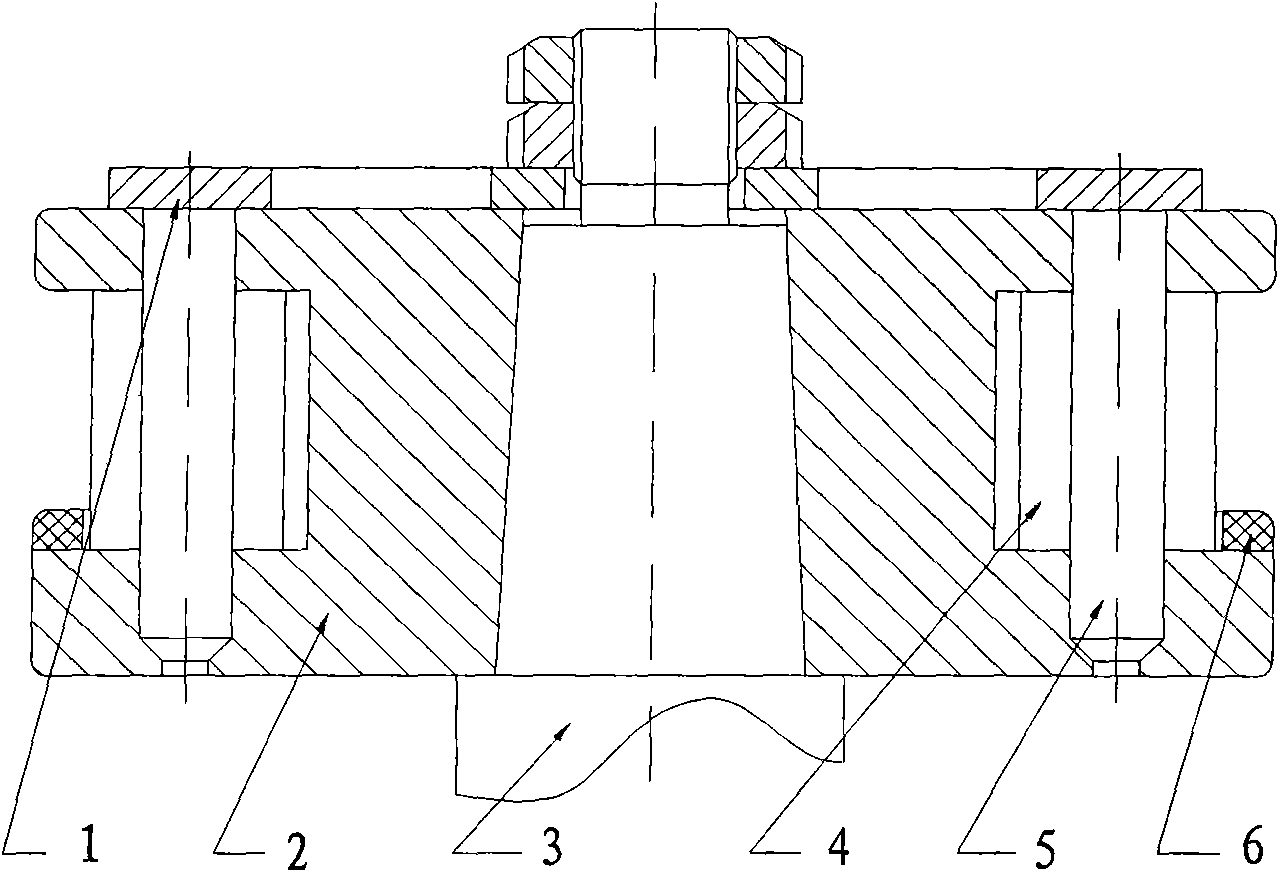

[0007] The present invention consists of a set of self-rotating planetary gears (4) looped on the planetary gear shaft (5), the planetary gear shaft (5) is placed on the drawing wheel (2), the pressure ring (1) and the anti-friction sheet (6) It is fixed on the pulling wheel (2) with screws; the pulling wheel (2) is driven by the transmission shaft (3).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to wire drawing production equipment of the wire product industry, in particular to a straight line type wire drawing machine, a loop type wire drawing machine and a pulley typecontinuous wire drawing machine. The wire drawing production equipment comprises a planet rolling intermediate winding drum of the wire drawing machine, which is assembled by a drawing wheel, a planetary wheel, a planetary wheel shaft, a chafing slice and a compression ring. The invention provides the planet rolling intermediate winding drum of the wire drawing machine, which has the effect of back pull drawing. The planet rolling intermediate winding drum of the wire drawing machine can eliminate an automatic speed regulation system with the complicated and expensive intermediate winding drumand obviously reduce equipment cost when used in the straight line type wire drawing machine and the loop type wire drawing machine; and the planet intermediate winding drum can make the pulley typecontinuous wire drawing machine have the property characteristics of the straight line type wire drawing machine and has obvious effect of back pull drawing when used as the intermediate winding drumof the pulley type continuous wire drawing machine. The magnitude of a drawing force of the planet rolling intermediate winding drum is determined by friction moment and the quantity of the planetarywheel; and when the wire slides off on the planet rolling intermediate winding drum, the planetary wheel can freely rotate and apply work by using the rolling friction moment of the planetary wheel. The wire drawing production equipment can obviously reduce drawing energy consumption, prolong the service life of grinding tools, and effectively solve the problem of scratching wires.

Description

technical field [0001] The invention relates to wire drawing production equipment in the wire product industry, in particular to an intermediate reel of a linear, looper and pulley continuous wire drawing machine. Background technique [0002] Linear and looper wire drawing machines are relatively advanced wire drawing production equipment in the world. The steel wire is almost straight from one reel to another, which is very suitable for continuous drawing of thick steel wire (Φ7-Φ18), high-strength steel wire (1200-1300Mpa) and special-shaped steel wire. When the linear and looper wire drawing machines are drawing, there is a reverse tension between the front and rear reels, which can significantly reduce the drawing energy consumption and prolong the service life of the abrasive tool. There is no sharp bending and axial torsion of the steel wire during the drawing process, so the performance of the finished product is better. However, the linear and loop-type wire drawi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B21C1/14

Inventor 严国语

Owner 严国语

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com