Device and process for homogenizing fabric dust collecting electrode surface water film

A fiber fabric and surface water film technology, applied in chemical instruments and methods, external electrostatic separators, separation methods, etc., can solve the problems of high cost and poor surface water film uniformity, and achieve low cost, strong adsorption, and durability. good thermal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

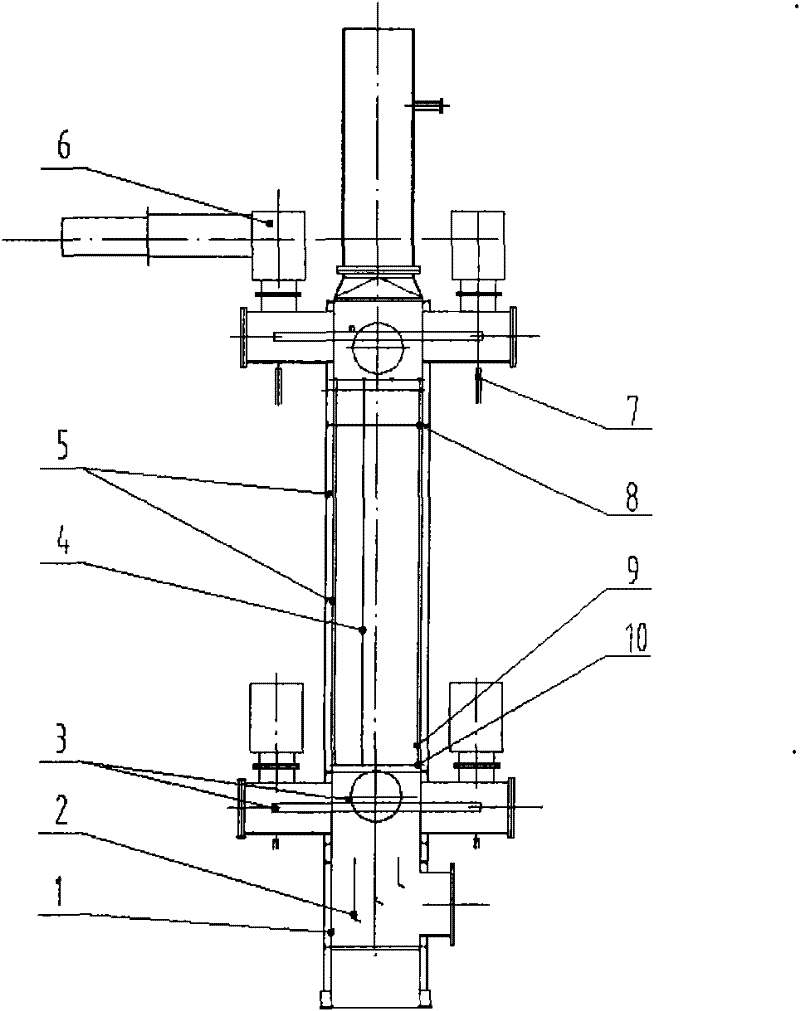

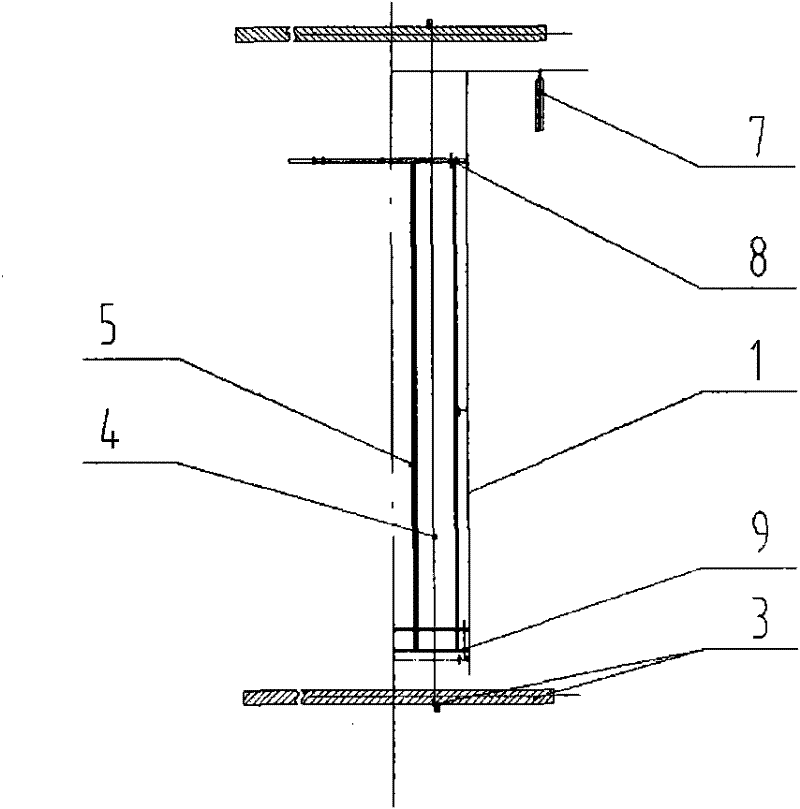

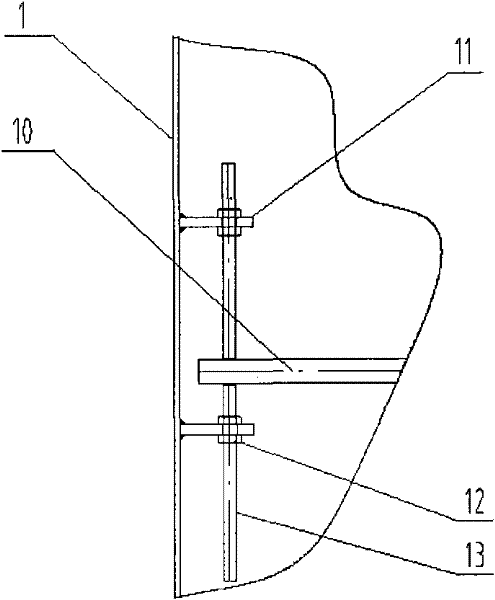

[0021] Combine below figure 1 and figure 2 , image 3 A best specific embodiment of the present invention is given. The process of homogenizing the water film on the surface of the fiber fabric dust collector is through figure 1 and figure 2 , image 3The device shown is realized. The flue gas passes through the casing 1 and flows through the deflector 2. After the flow state is homogenized, it enters the dust collection pole square tube 5. The upper end of the dust collection pole square tube 5 is positioned by the film cloth device 8, and the lower end of the dust collection pole square tube The pole length adjusting device 9 and the homogenizing rod 10 are positioned, and the homogenizing rod 10 pre-applies an average tension force to the dust collecting pole of the fiber fabric, so that it is in a state of elastic deformation, ensuring the straight effect of the dust collecting pole of the fiber fabric, and The discharge electrode 4 maintains a fixed pole spacing a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com