Dense-medium shallow-groove separating and waste-rock exhausting system used under coal mine

A technology of heavy medium shallow trough and underground gangue discharge, which is applied in solid separation, wet separation, chemical instruments and methods, etc. Construction and maintenance costs and the effect of reducing transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

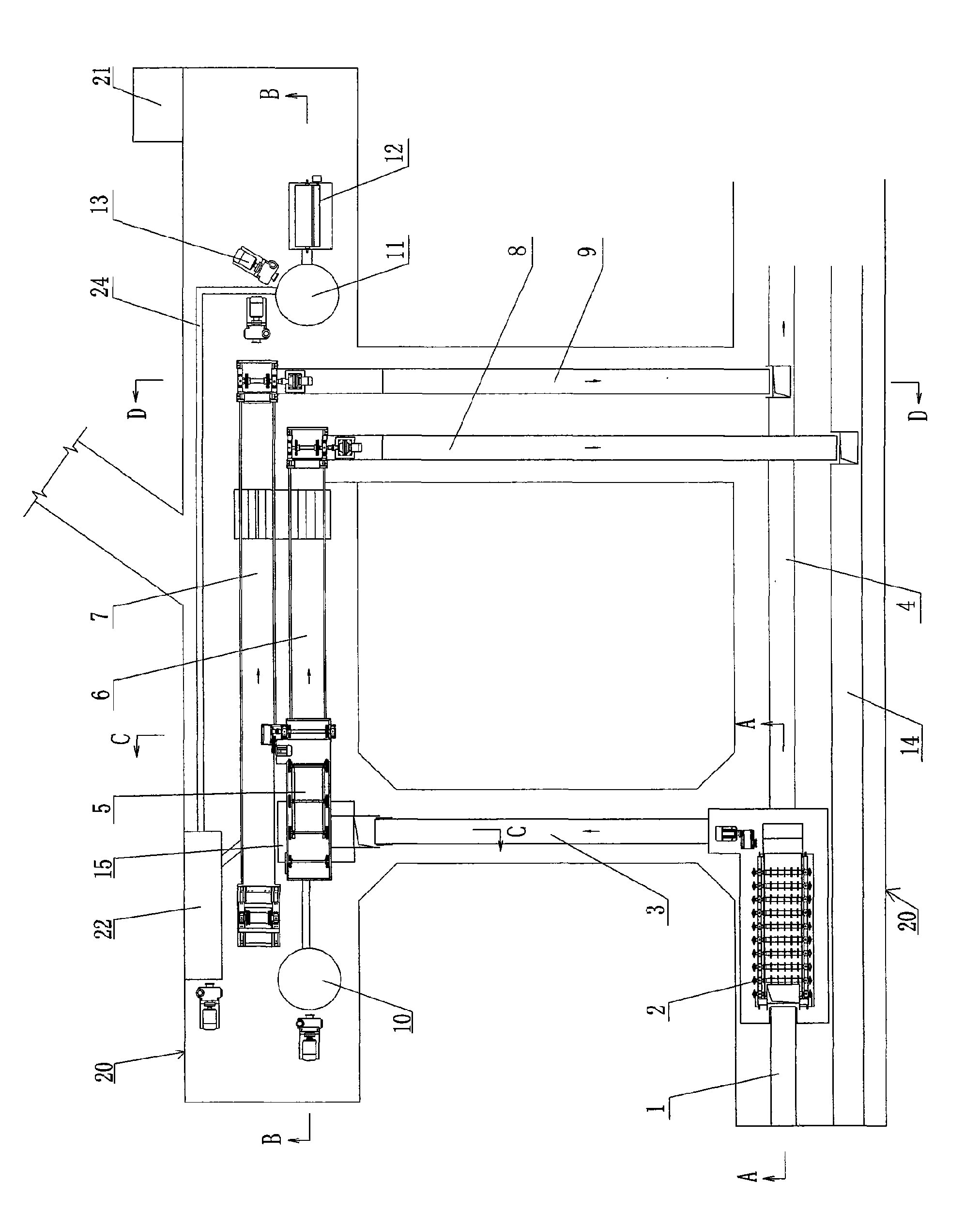

[0020] Such as Figure 1 to Figure 5 As shown, an underground gangue discharge system for dense medium shallow tank separation, including raw coal belt conveyor 1, roller screen 2, lump coal belt conveyor 3, fine coal belt conveyor 4 under the screen, dense medium shallow tank separator 5 , Gangue de-medium scraper conveyor 6, clean coal de-medium scraper conveyor 7, first gangue belt conveyor 8, cleaned coal belt conveyor 9 after selection, qualified medium barrel 10, dilute medium barrel 11, magnetic separator 12, slurry Pump 13, second gangue belt conveyor 14, electric control room 21, sump 22, sump 23 and pipeline 24;

[0021] The raw coal belt conveyor 1 is installed on the side of the feed end of the roller screen 2, the fine coal belt conveyor 4 under the screen is installed under the roller screen 2, the oversize material discharge end of the roller screen 2 and the dense medium shallow groove A lump coal belt conveyor 3 is installed between the feed ports of the sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com