Curable resin composition, led package, and method for production of the led package, and optical semiconductor

A curable resin and composition technology, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of difficulty in controlling the thickness of the sealing resin, slow curing of the thermosetting resin, and easy mixing of the sealing resin into the voids. High performance, improved life or reliability, and superior optical or mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

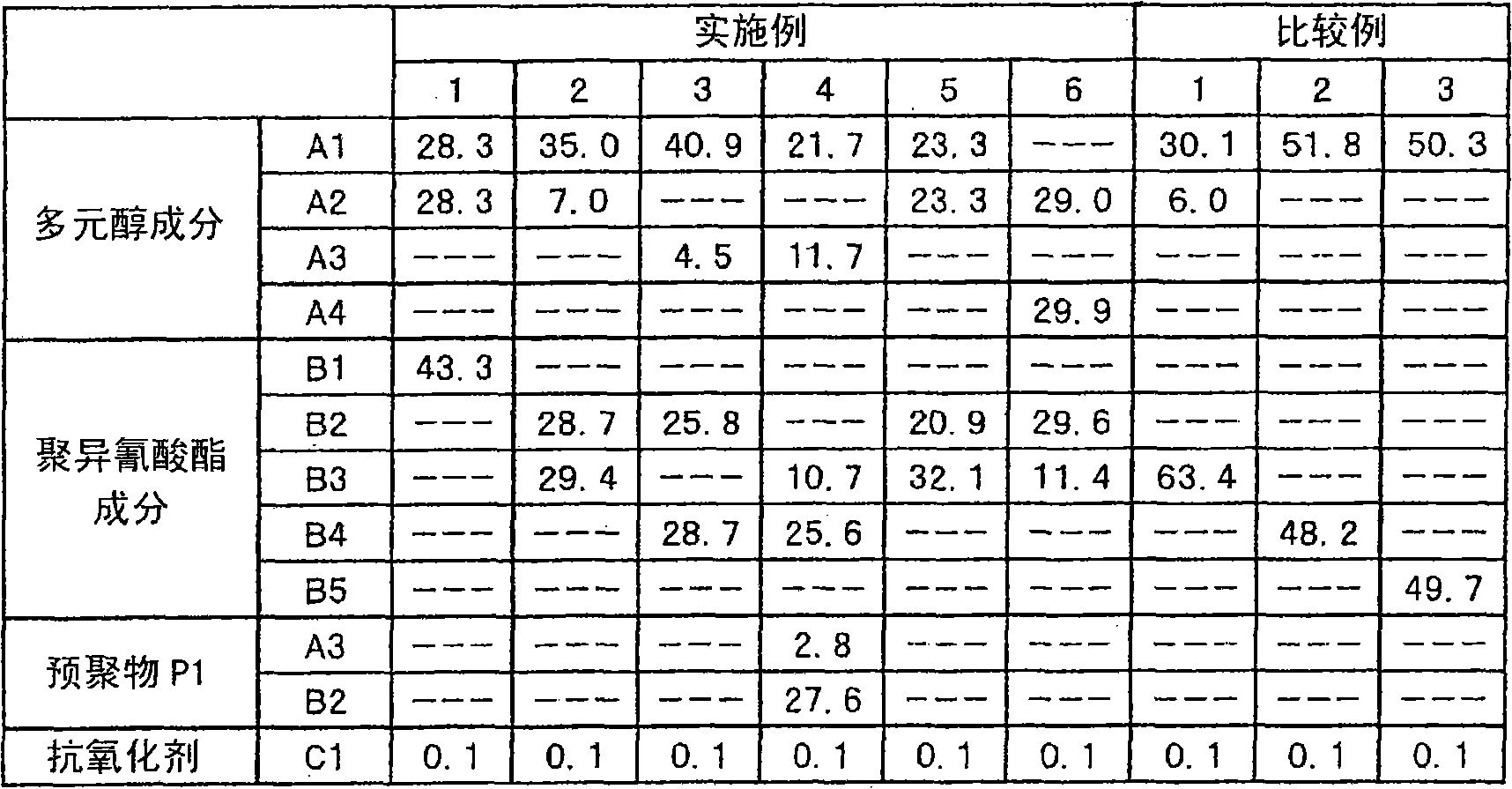

[0150] As a polyol component, 28.3 parts by mass of polycaprolactone triol A1 (manufactured by Daisy Road Chemical Industry Co., Ltd., trade name "Plaxil 303") having a weight average molecular weight of 300 and a hydroxyl value of 540 mgKOH / g and Weight-average molecular weight: 500 and hydroxyl value: 230 mgKOH / g polycarbonate diol A2 (manufactured by Daishiro Chemical Industry Co., Ltd., trade name "Prachill CD205PL") 28.3 parts by mass, and as a polyisocyanate component, isocyanate 43.3 parts by mass of phorone diisocyanate B1 (manufactured by Digesa Japan Co., trade name "IPDI") and [2-{3-(3-tert-butyl-4-hydroxyl-5) as a hindered phenolic antioxidant -methylphenyl)propionyl}-1,1-dimethylethyl]-2,4,8,10-tetraoxaspiro[5,5]undecane C1 (manufactured by Sumitomo Chemical Co., trade name "Smilite GA-80") 0.1 parts by mass, the mixture mixed as above was uniformly dispersed and dissolved by ultrasonic dispersion, and degassed under reduced pressure to obtain solution S1 of a cur...

Embodiment 2

[0154] 35.0 parts by mass of the above-mentioned polycaprolactone triol A1 as a polyol component, 7.0 parts by mass of the above-mentioned polycarbonate diol A2, and 28.7 parts by mass of 4,4'-methylenebis( Cyclohexyl isocyanate) B2 (manufactured by Digesa Japan Co., trade name "H 12 MDI"), 29.4 parts by mass of isocyanate-type triisocyanate B3 (manufactured by Asahi Kasei Chemicals Co., Ltd., trade name "Dulite THA-100"), and 0.1 parts by mass of the above-mentioned [2- {3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionyl}-1,1-dimethylethyl]-2,4,8,10-tetraoxaspiro[5 , 5] Undecane C1, the mixture mixed as above was uniformly dispersed and dissolved by ultrasonic dispersion, and then degassed under reduced pressure to obtain a solution S2 of a curable resin composition.

[0155] Next, except having used the solution S2 of this curable resin composition instead of solution S1 of curable resin composition, it carried out similarly to Example 1, and completed the LED package.

Embodiment 3

[0157] 40.9 parts by mass of the above-mentioned polycaprolactone triol A1 as a polyol component, 4.5 parts by mass of trimethylolpropane A3 (manufactured by Perstorp), and 25.8 parts by mass of the above-mentioned 4,4'-ethylene oxide as a polyisocyanate component were mixed. Methyl bis(cyclohexyl isocyanate) B2, 29.7 parts by mass of 1,3-bis(isocyanate methyl)cyclohexane B4 (manufactured by Mitsui Chemicals Polyurethane Co., Ltd., trade name "Tacnut T600"), and 0.1 parts by mass The above-mentioned [2-{3-(3-tert-butyl-4-hydroxy-5-methylphenyl)propionyl}-1,1-dimethylethyl]-2 as a hindered phenolic antioxidant , 4,8,10-tetraoxaspiro[5,5]undecane C1, the mixture mixed as above was uniformly dispersed and dissolved by ultrasonic dispersion, and then degassed under reduced pressure to obtain a curable resin Composition of solution S3.

[0158] Next, except having used the solution S3 of this curable resin composition instead of solution S1 of curable resin composition, it carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel time | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com