Motor control method based on DCS system

A DCS system, motor control technology, applied in the direction of motor control, control system, electrical components, etc., can solve the problems of time-consuming, low level of human-computer interaction settings, reduce fault finding time, etc., to improve safety and increase the amount of information. and maintainability, the effect of improving readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

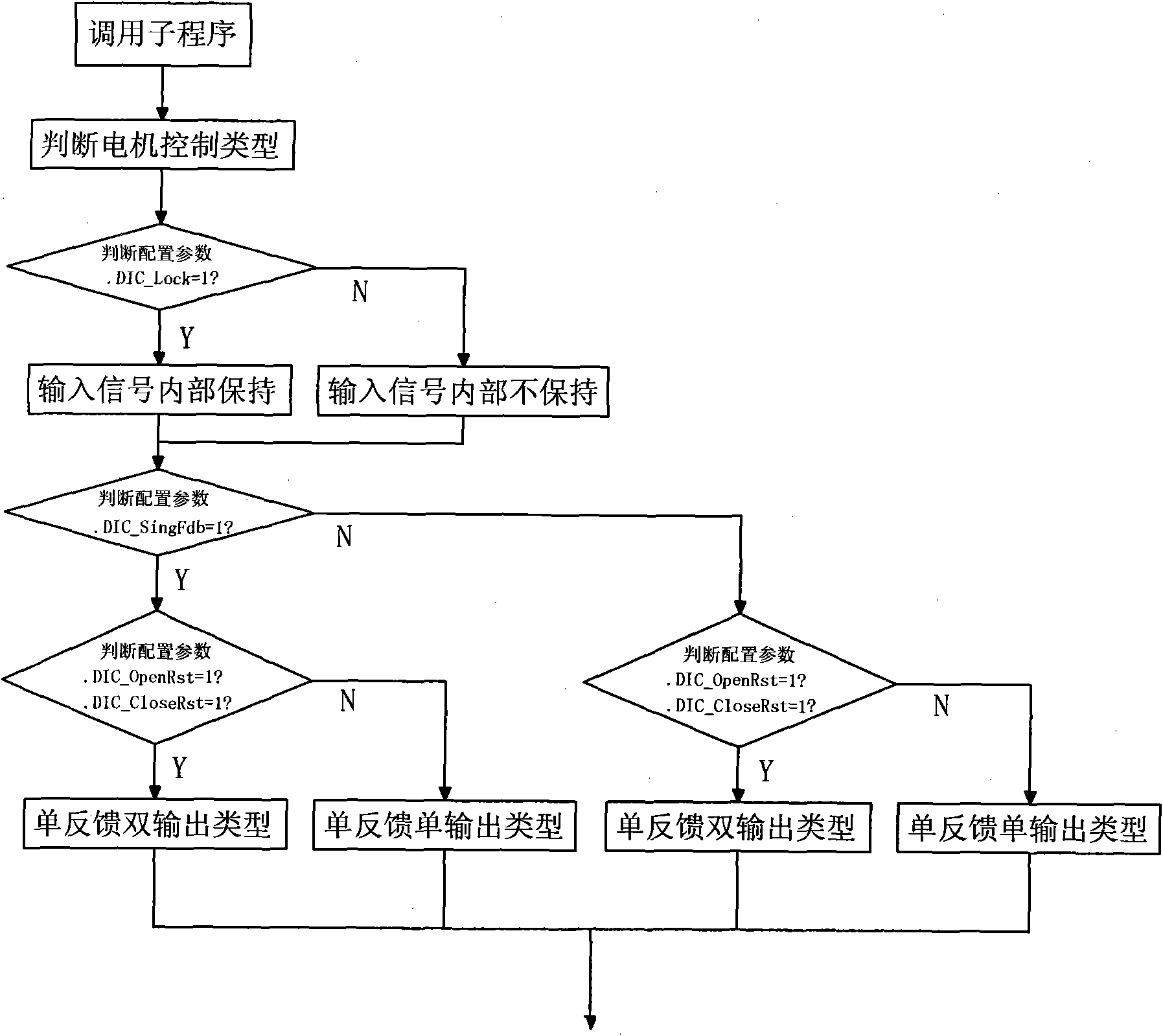

[0020] Attached below Figure 1 to Figure 6 The present invention is described in further detail with embodiment:

[0021] Embodiments The motor control method based on the DCS system is to set the motor operation and control parameters by the computer through network communication to realize the operation and control of the motor. The DCS system includes a control motor and a host computer connected to the control motor. The host computer There is a switch between the control motor and the control motor. There are several different types of motors connected to the control motor, and a standard motor module is installed inside the control motor. After setting the parameters, call the motor subroutine, realize signal processing and control of different types of motors by calling the standard motor module, and then return to the main body program that controls the motor after the subroutine processing is completed, and at the same time output the corresponding Control commands,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com