Disinfection device

A disinfection device and disinfectant technology, which is applied in disinfection, water supply equipment, construction, etc., can solve the problems of delaying the replacement of disinfectant, and achieve the effect of easy confirmation and lightening the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

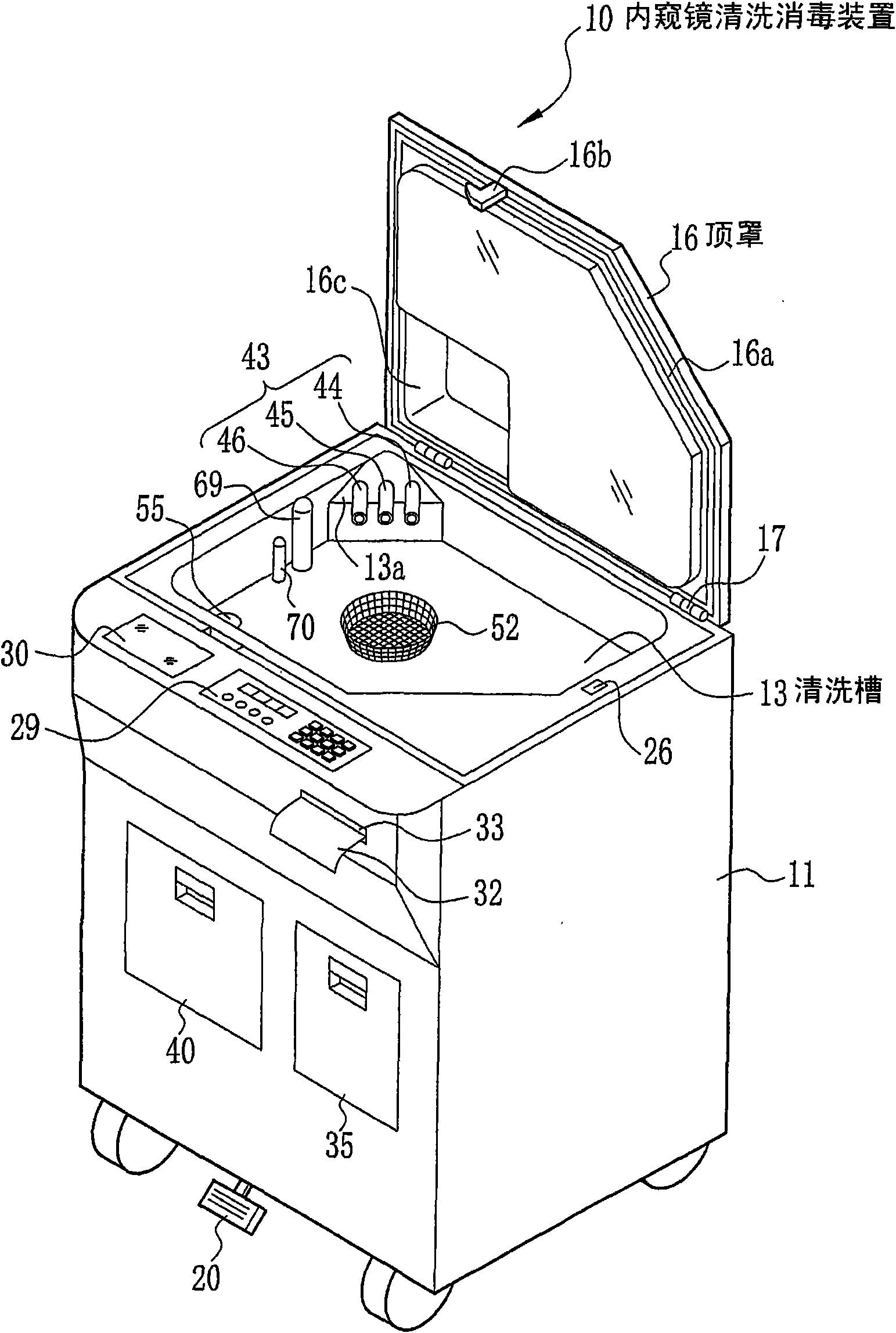

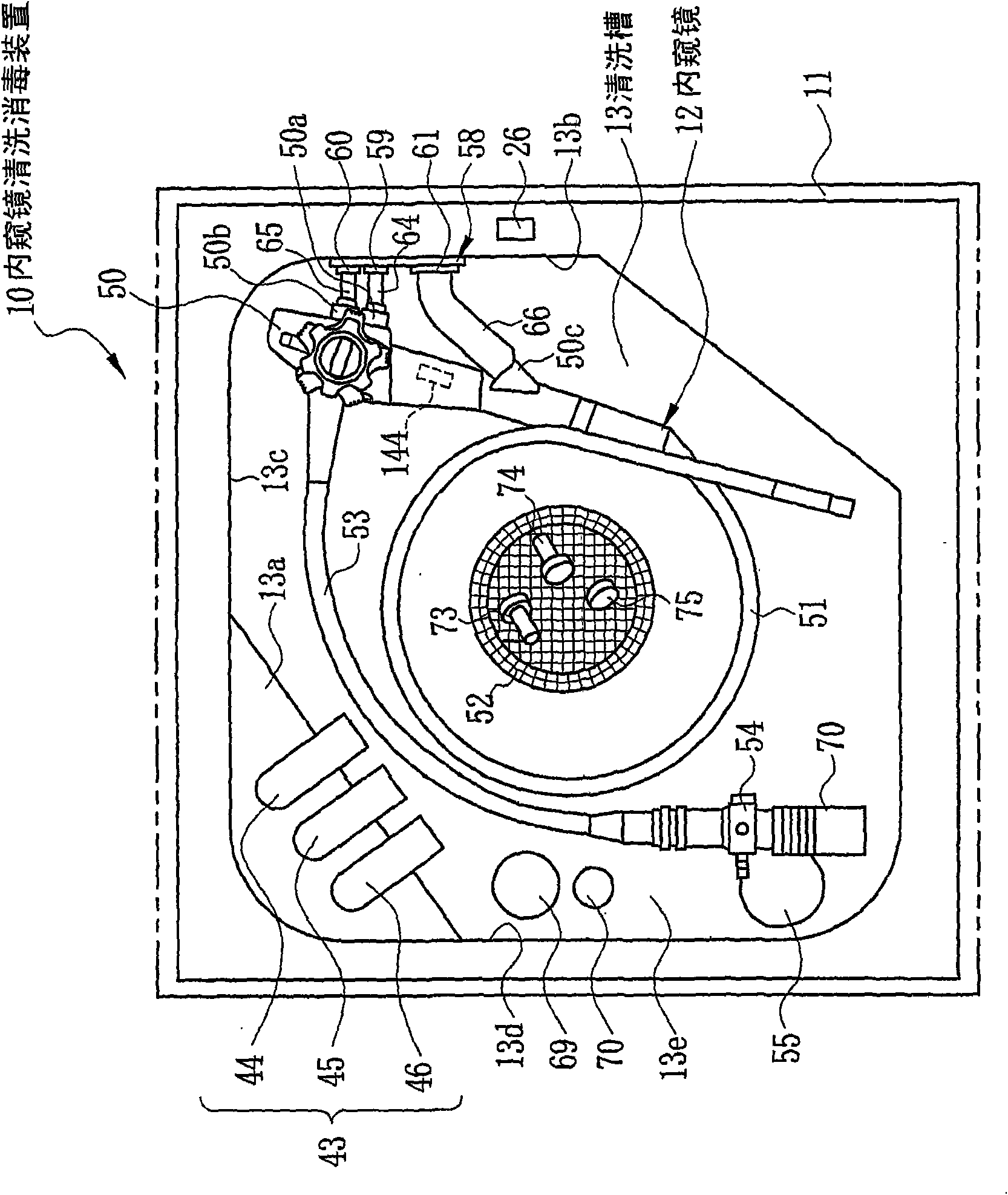

[0061] figure 1 The shown endoscope cleaning and disinfection device (hereinafter simply referred to as device) 10 has a box-shaped device body 11 . The upper surface of the device main body 11 is provided with an endoscope 12 for accommodating use (refer to figure 2 ) of the cleaning tank 13. The cleaning tank 13 is a water tank with an open upper part, and is formed of a metal plate excellent in heat resistance, corrosion resistance, etc., such as stainless steel, for example.

[0062] A top cover 16 covering the upper portion of the cleaning tank 13 is provided on the upper portion of the apparatus main body 11 . The top cover 16 is, for example, a substantially rectangular plate-shaped body made of transparent plastic, and one side is pivotally supported by a hinge 17 provided on the upper surface of the device main body 11 so as to be freely openable and closable. A packing 16 a for sealing the inside of the cleaning tank 13 is provided on the inner periphery of the t...

no. 2 approach

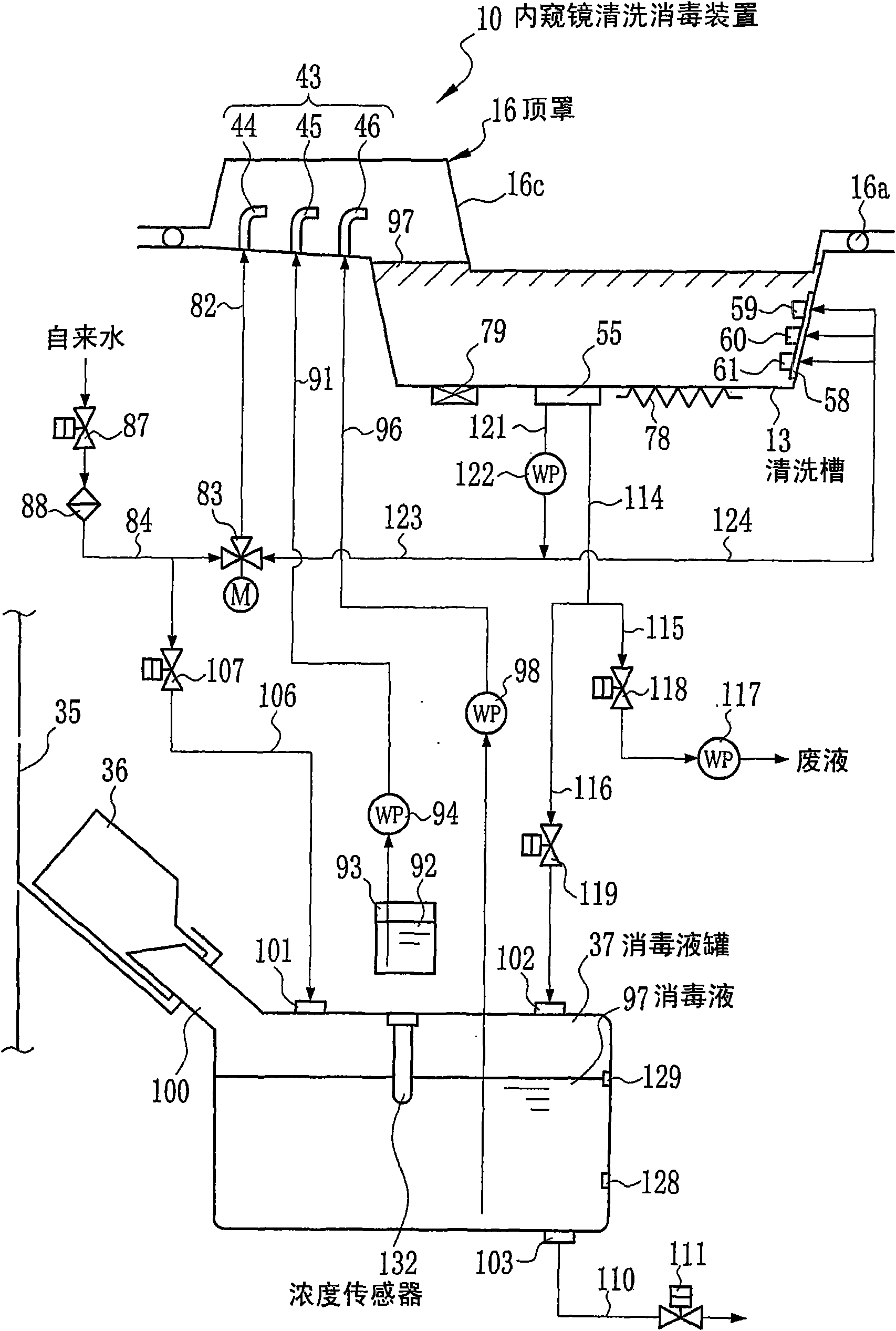

[0147] Such as Figure 8 As shown, the replacement work of the disinfectant solution 97 takes a corresponding amount of time. When it is necessary to urgently clean and disinfect the endoscope 12 and the time for replacing the disinfectant solution 97 is reached, if the disinfectant solution is replaced, cleaning and disinfection followed by endoscopic examination will delay the time for disinfectant solution replacement. Therefore, a mechanism for additionally supplying the stock solution of the disinfectant solution 97 to the disinfectant solution tank 37 is provided, and cleaning and disinfection can be performed several times in an emergency without performing replacement work. In addition, components having the same structure and function as those of the above-mentioned embodiments are assigned the same reference numerals, and description thereof will be omitted.

[0148] exist Figure 10 Among them, the device 200 has a sub-tank 202 storing a stock solution 201 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com