Application of oxygen hydrogen gas in shock tank blasting and soot blowing method

A shock wave tank, hydrogen-oxygen technology, which is applied in the field of blast wave soot blowing, can solve the problems of insufficient and uneven mixing of gas and air, and the soot blowing efficiency cannot meet the design requirements, and achieves good soot blowing effect and consistency. , the effect of long distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

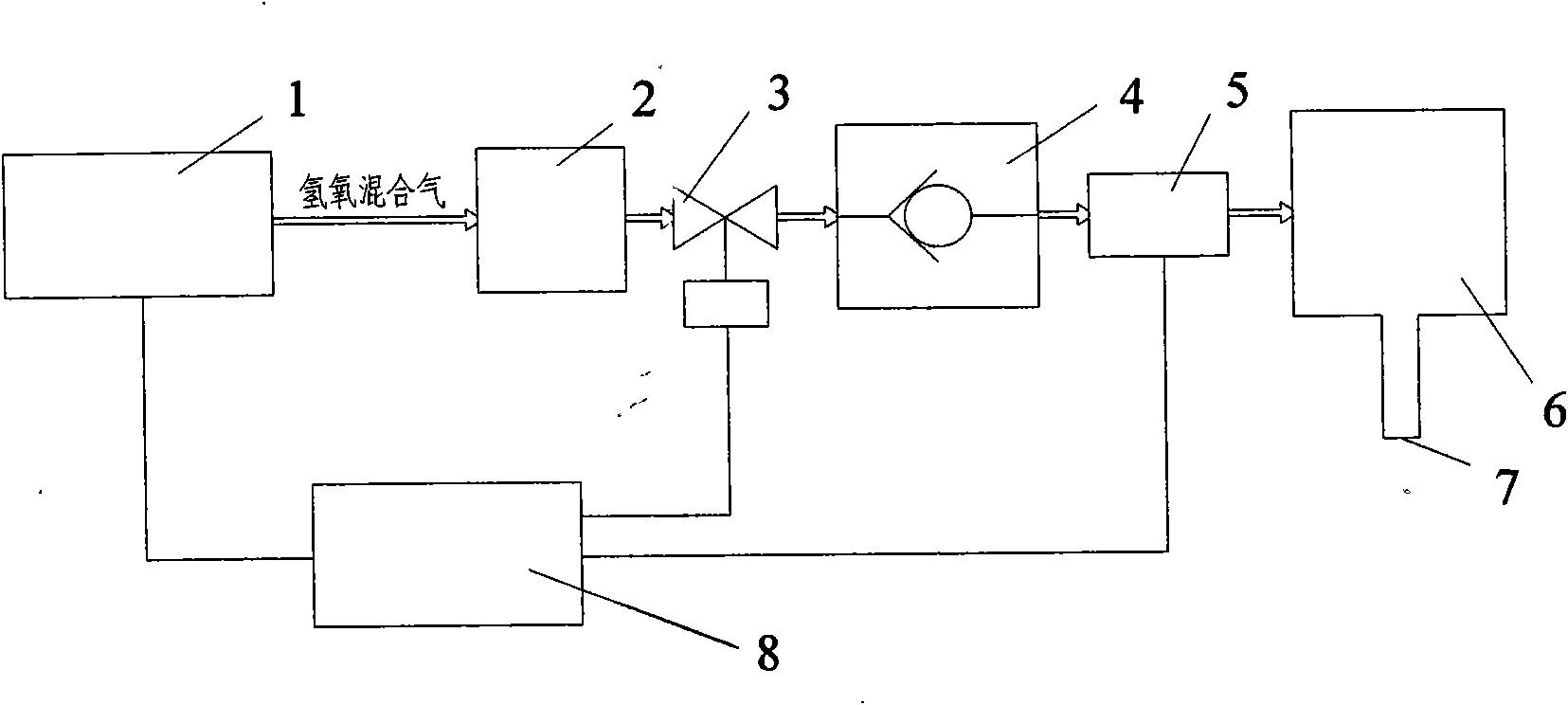

Embodiment 1

[0017] This embodiment is a method of using an electrolyzed water device to generate an equivalent ratio of hydrogen-oxygen mixture to carry out deflagration and soot blowing, such as figure 1 As shown, the electrolyzed water device 1 produces 0.1 cubic hydrogen and oxygen molar equivalent per minute of hydrogen-oxygen mixture through the flame arrester 2, solenoid valve 3, check valve 4 and ignition tank 5 and enters the shock wave tank with a volume of 0.01 cubic 6. The solenoid valve is controlled by the controller 8 to open the solenoid valve for 3 hours and 6 seconds to fill the shock tank 6 with air, close the solenoid valve 3, and control the ignition time for 0.1 seconds to ignite through the ignition tank 5, and the hydrogen-oxygen mixture in the shock tank 6 will be ignited. It will detonate and produce ultra-high-speed explosion waves, which will be sprayed out through the pulse nozzle 7, acting on the ash accumulation on the heating surface of the boiler to make it ...

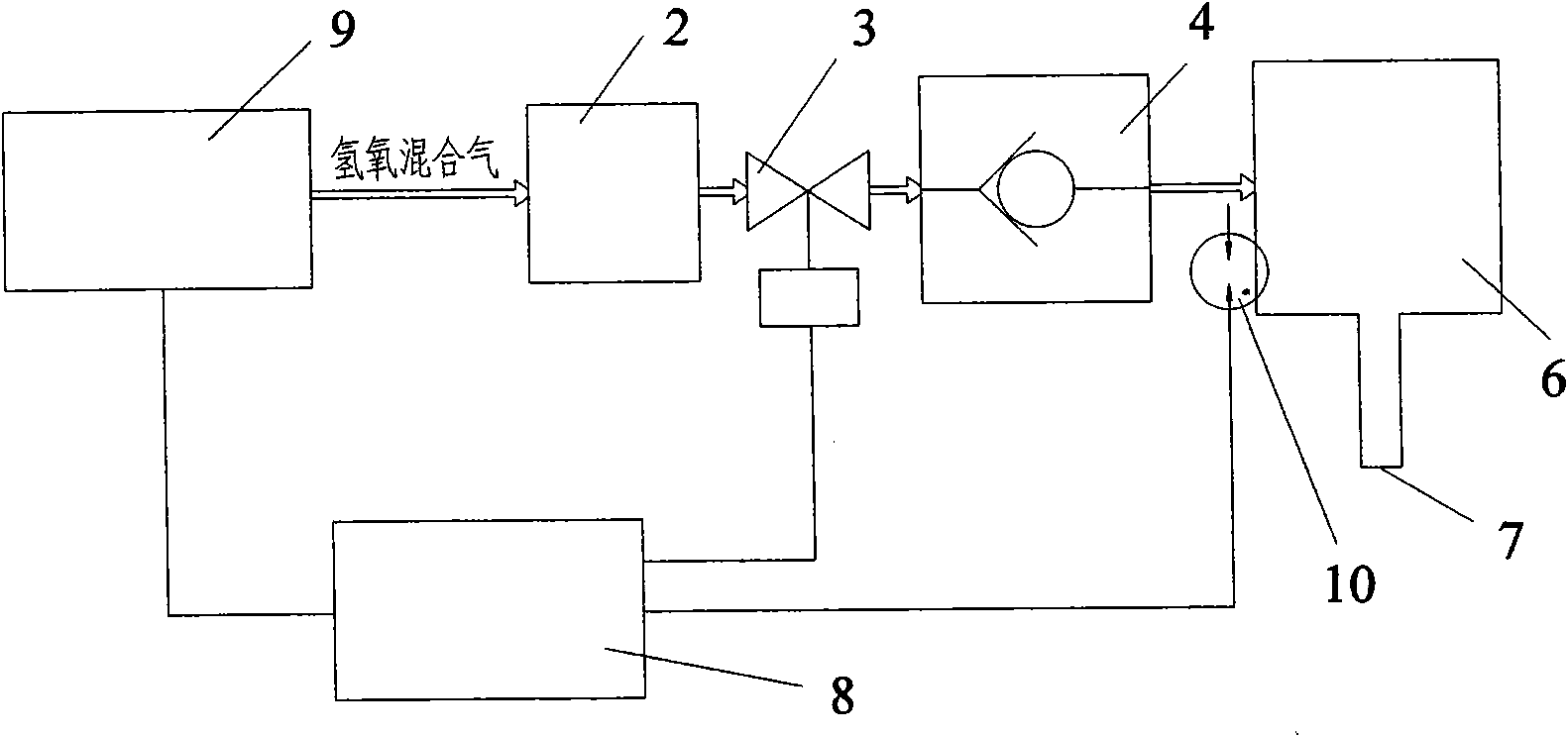

Embodiment 2

[0019] This embodiment is a method of utilizing a solar hydrogen-oxygen generator to produce an equivalent ratio of hydrogen-oxygen mixture to carry out deflagration and soot blowing, such as figure 2 As shown, the hydrogen-oxygen mixture produced by the solar hydrogen-oxygen generator 9 at a molar equivalent ratio of 0.01 cubic hydrogen per minute passes through the flame arrester 2, the solenoid valve 3 and the one-way valve 4 and enters the shock tank 6 with a volume of 0.01 cubic. Controlled by the controller 8, the electromagnetic valve is opened for 3 hours and 1 minute to fill the shock tank 6 with air, and the solenoid valve 3 is closed. At the same time, the ignition time is controlled to be ignited by the igniter 10 within 0.1 seconds, and the hydrogen-oxygen mixture in the shock tank 6 will be Combustion and explosion generate ultra-high-speed explosion waves, which are ejected through the pulse nozzle 7 and act on the ash deposits on the heating surface of the boil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com