Drive system for a fitting

A technology of driving device and transmission device, applied in door/window accessories, wing parts, hinges with pins, etc., can solve the problems of laborious opening and closing of flip accessories, increase manufacturing costs, etc., and achieve the effect of reducing storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

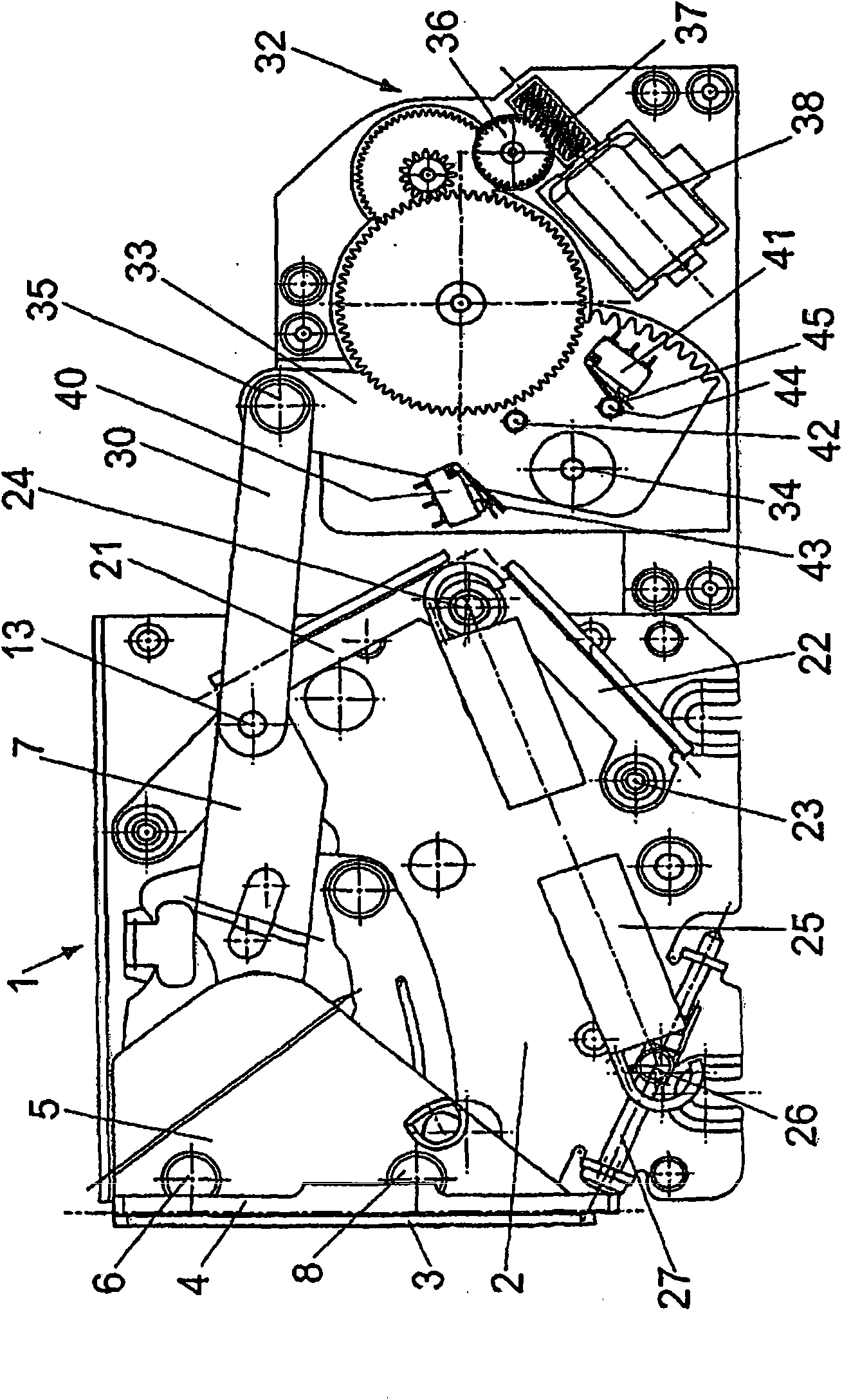

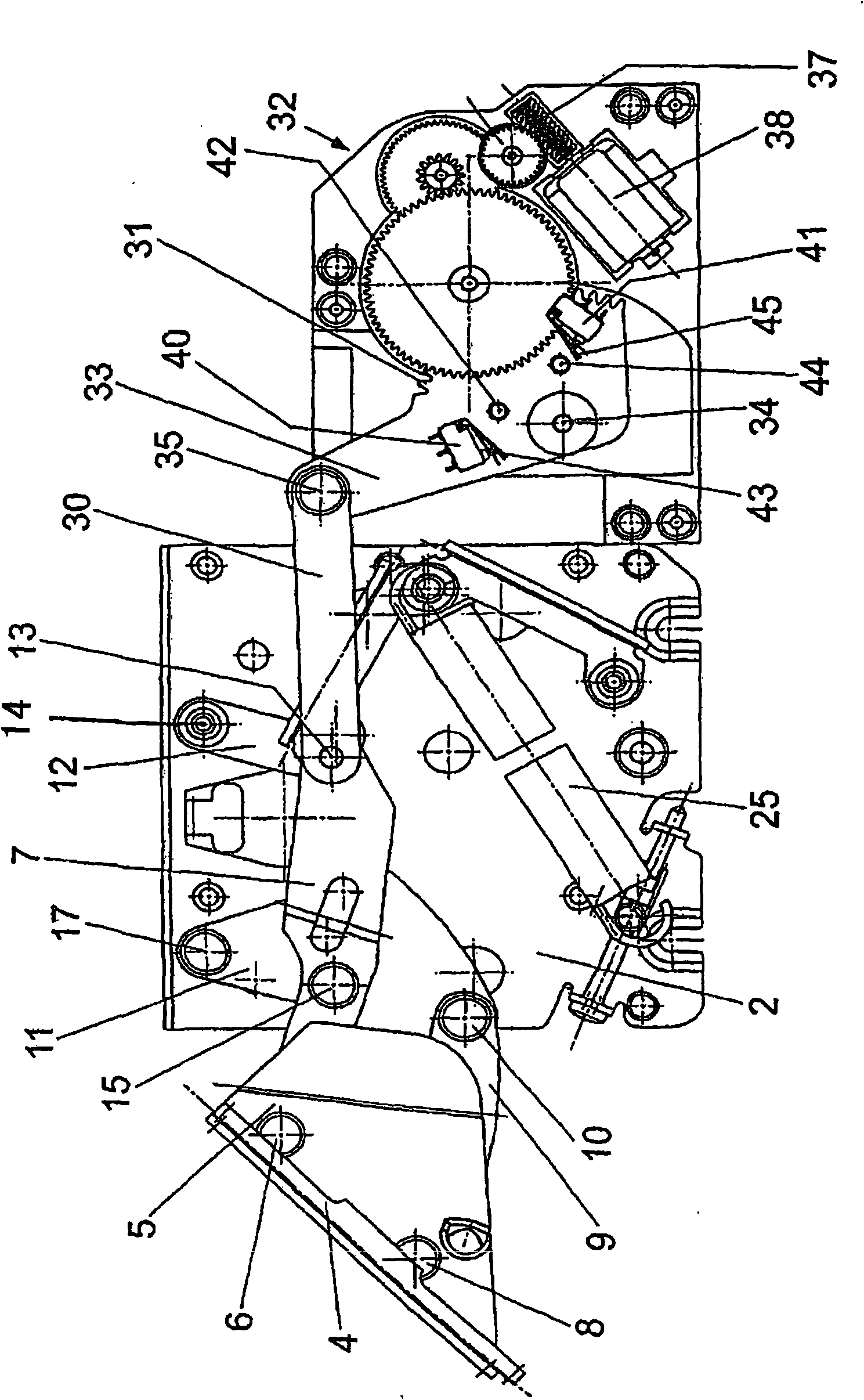

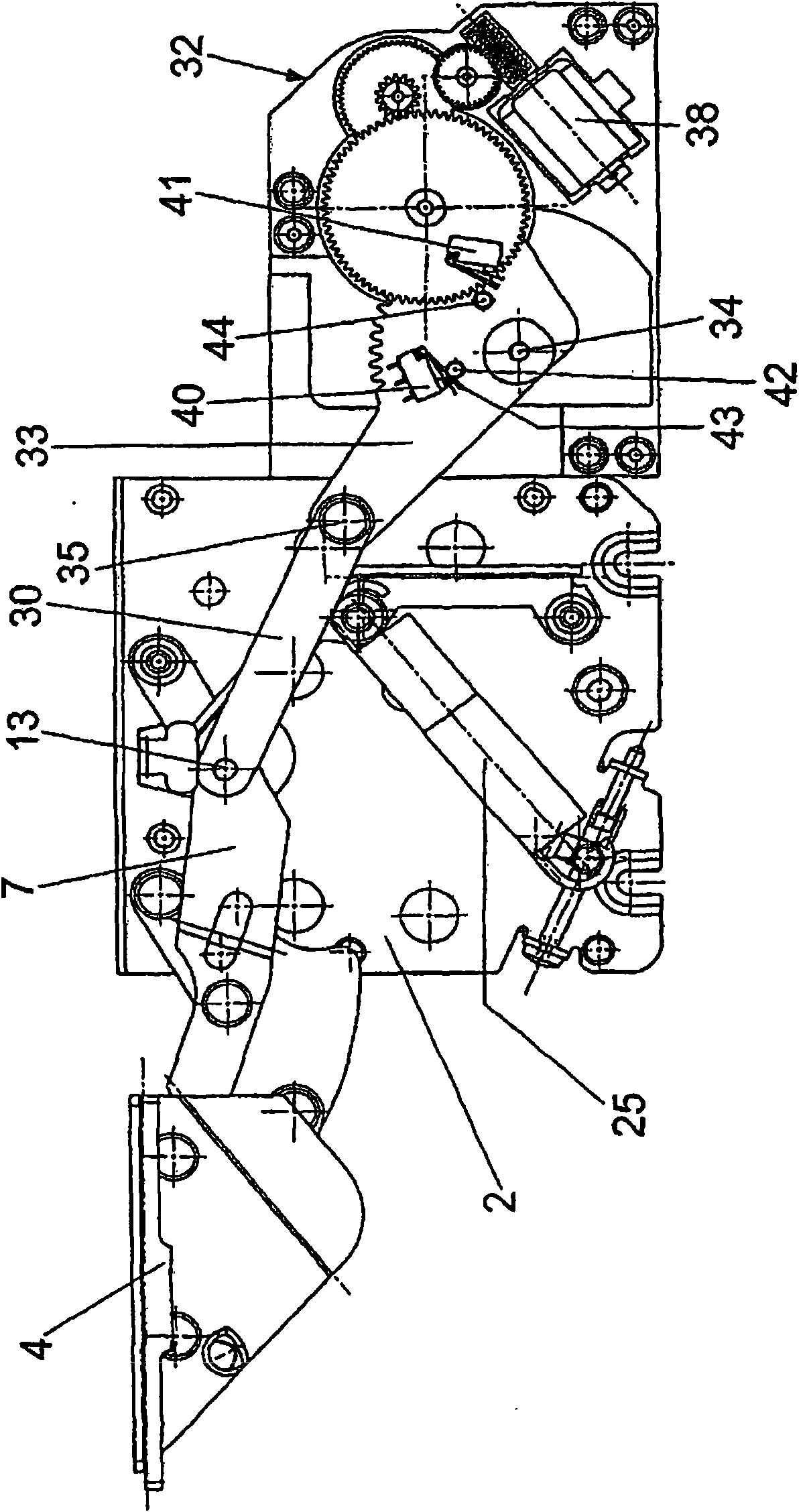

[0019] figure 1 shows a drive for a flap fitting 1 which is mounted or fixable via a fastening plate 2 on a furniture, preferably a cabinet. The flap fitting 1 comprises a pivot element 4 on which a plate 3 is arranged for connection to a flap. The rotary element 4 is angular and has, on a section 5 perpendicular to the plane of the plate 3 , an articulation axis 6 on which a guide lever 7 is mounted. A further shaft 8 is formed in the part 5 at a distance from the shaft 6 , on which a further guide lever 9 is rotatably mounted.

[0020] The end of the guide lever 9 remote from the rotary element 4 is connected via a shaft 10 to a first lever 11 , which is likewise hinged to the guide lever 7 on a shaft 15 . At a distance from the first lever 11 supported on a shaft 17 on the fixed plate 2, a second lever 12 is arranged, which is hinged on one side via a shaft 13 to the guide lever 7 and at the other end via a shaft 14. It is hingedly connected with the fixed plate 2.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com