Biomass briquette gasification direct combustion combustor

A briquette fuel and biomass technology, which is applied in the direction of solid fuel combustion, combustion equipment, joint combustion mitigation, etc., can solve the problems that are difficult to meet the needs of industrial furnaces, low power of biomass combustion furnaces, complex gas distribution and air distribution, etc. , to achieve obvious energy-saving effect, compact structure, and high-efficiency heat energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

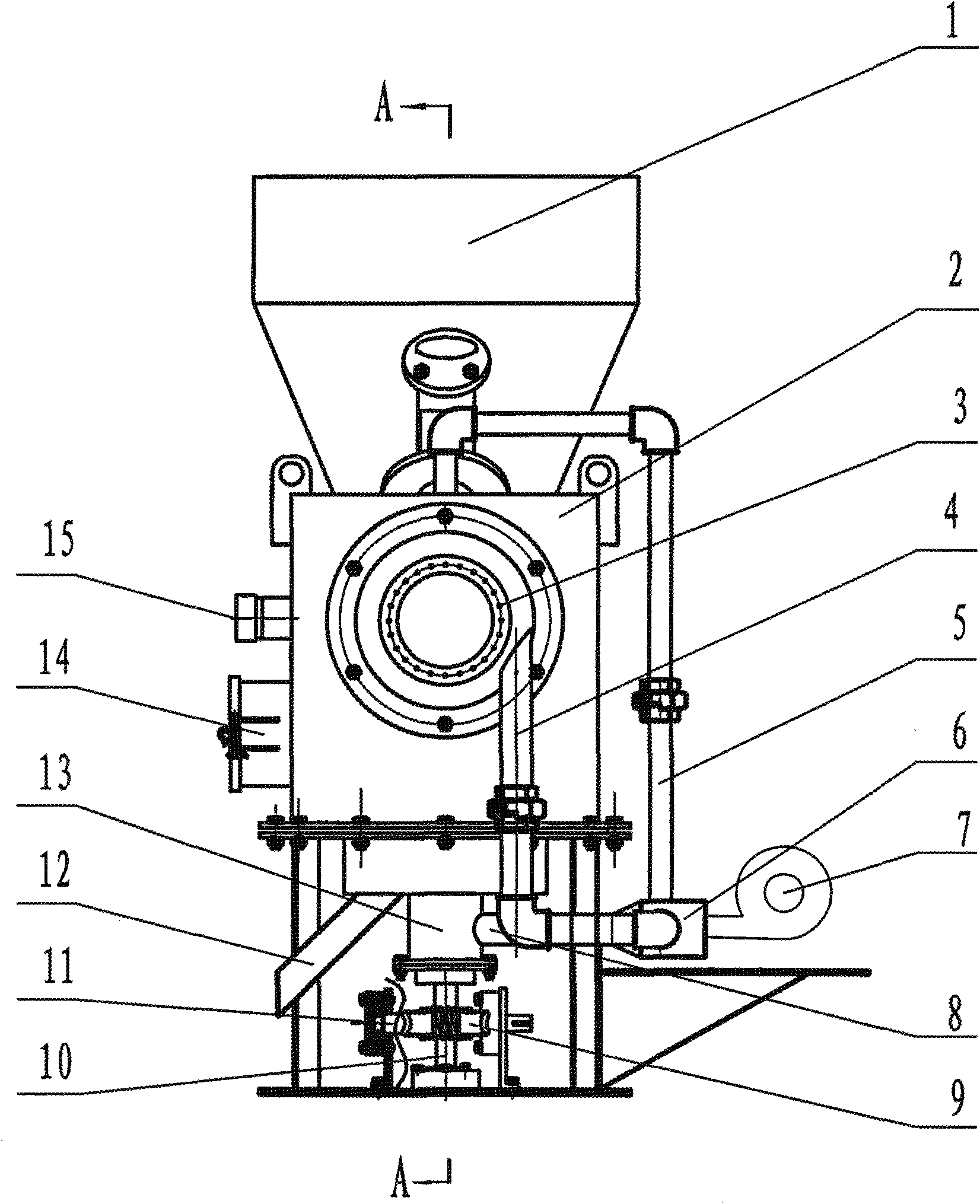

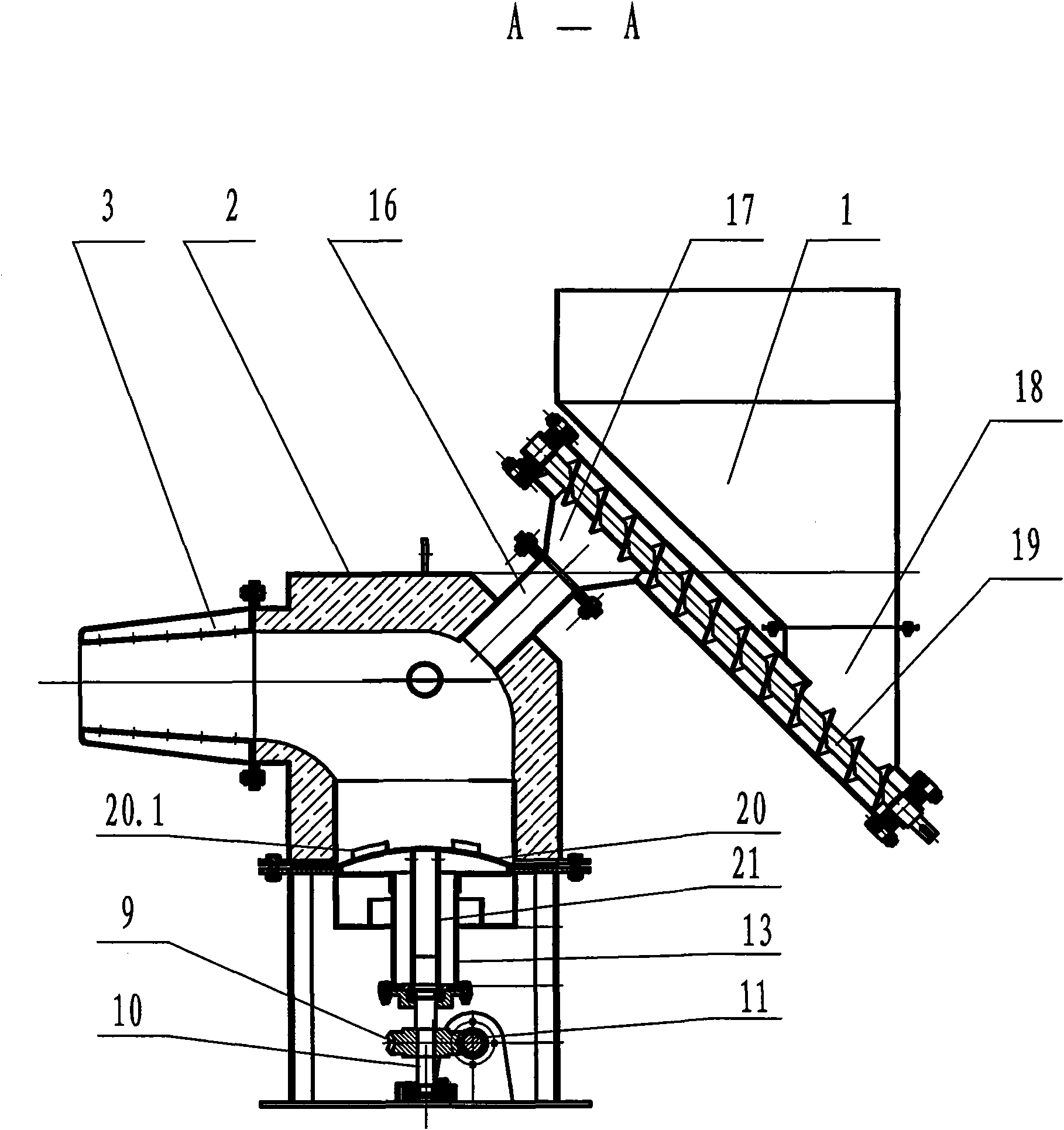

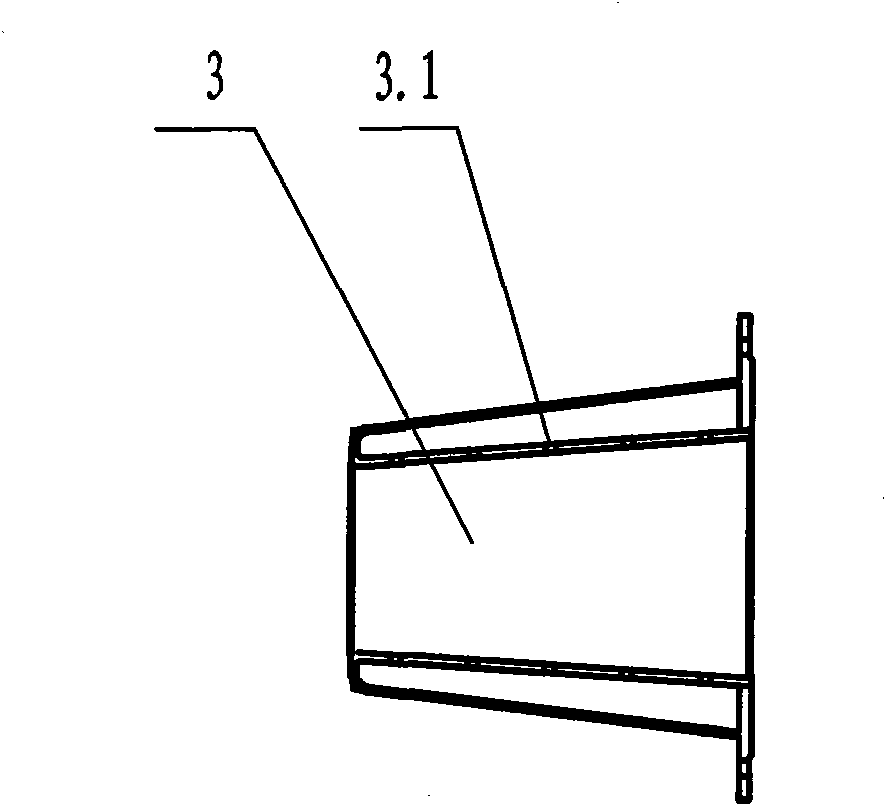

[0033] Such as Figure 1-5 As shown, a direct-fired burner for gasification of biomass briquette fuel, which includes a furnace body 2 and a bracket, the furnace body 2 is supported on the bracket, the side wall and the top wall of the furnace body 2 are designed with a layer of insulating material, and the furnace body The wall is also designed with a furnace door 14 for cleaning and maintenance and an observation port 15 for observing the flame combustion status. The bottom of the furnace body is fixedly connected with a bottom bracket, and a through hole is designed in the middle of the bottom bracket; , the surface of the fire grate 20 is a spherical crown surface, and the bottom is sealed by a sealing plate to form a cavity, on which there are evenly opened fire grate air holes 20.2, and a vertical plate-shaped stirring scraper 20.1 is designed on the upper surface of the fire grate. The lower part of the row is connected with a grate rotating shaft 21; an air inlet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com