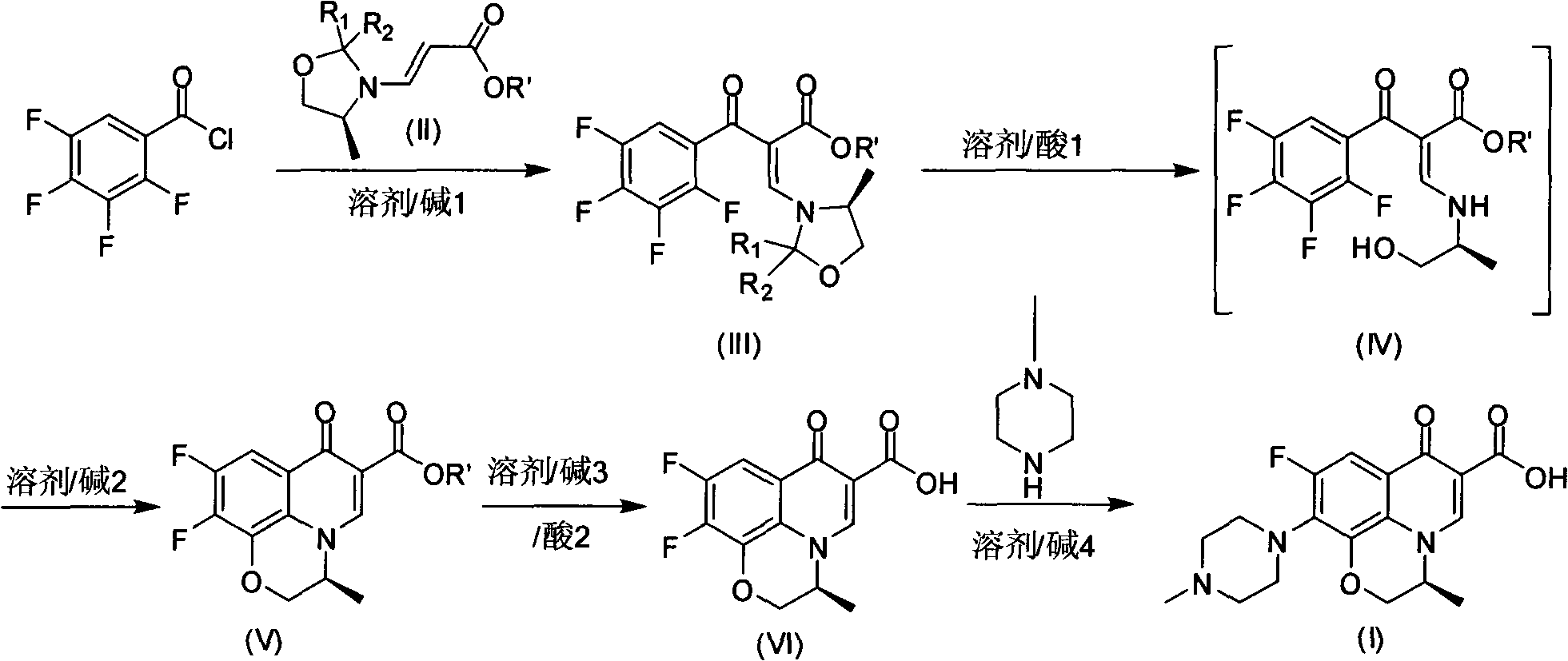

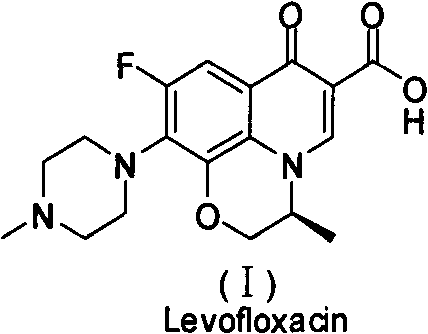

Method for preparing levofloxacin

A technology of levofloxacin and synthesis method, applied in organic chemistry and other directions, can solve the problems of poor atom economy, many three wastes, low yield and the like, and achieve the effects of reducing production cost, improving reaction yield and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments.

[0025] It uses tetrafluorobenzoyl chloride as raw material to prepare S-9,10-difluoro-2,3-dihydro-3-methyl-7-oxo-7H-pyrido[1,2,3- de]-[1,4]-benzoxazine-6-carboxylic acid (compound VI), then react with base 4 in an organic solvent to obtain levofloxacin, characterized in that S-9,10-difluoro -2,3-dihydro-3-methyl-7-oxo-7H-pyrido[1,2,3-de]-[1,4]-benzoxazine-6-carboxylic acid is synthesized as follows :

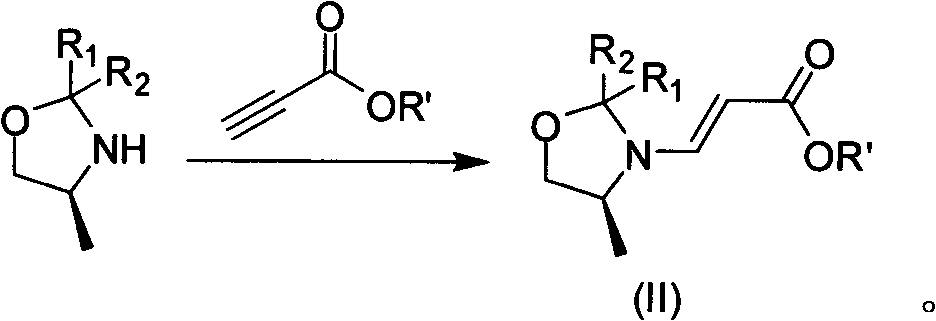

[0026] a) Under stirring at room temperature, add base 1 and tetrafluorobenzoyl chloride to the solution of compound II, raise the temperature to 50-90°C, and stir for 2-5 hours to obtain a solution of compound III; add acid 1 under stirring In the solution of compound III, stir at 20-50°C for 10-60 minutes to obtain a solution of compound IV; add an appropriate amount of water to the solution of compound IV to separate layers, extract, and dry to obtain an organic layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com