Process for preparing LixFeyPzO4 from ferrophosphorus

A technology of NH4H2PO4 and ferrophosphorus, which is applied in the field of material manufacturing process, can solve the problems of high preparation cost and single raw material, and achieve the effects of improving performance, eliminating pollutant discharge, and green, environmental protection and clean production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

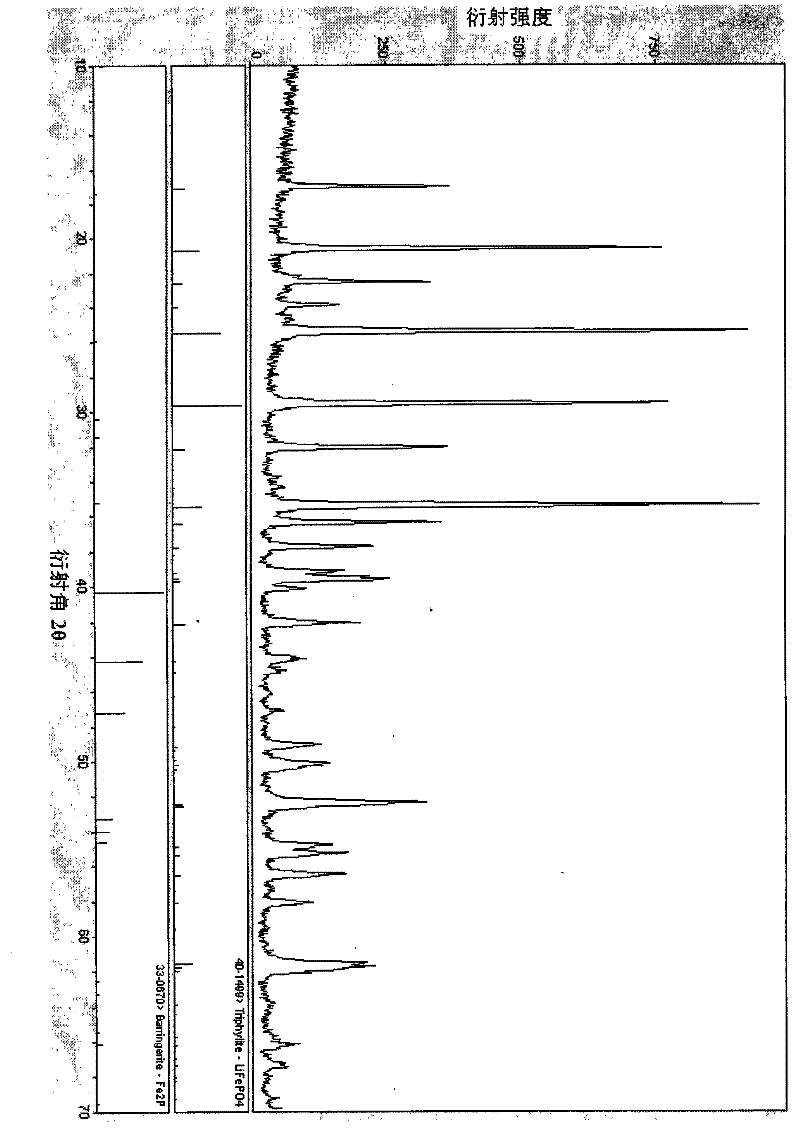

[0023] The by-product phosphorus iron Fe of thermal phosphoric acid was analyzed by rheological phase method. 1.5 P as raw material to prepare LiFePO 4 As the positive electrode material, first crush ferrophosphorus to a certain particle size, use ferrophosphorus powder as the iron source and part of the phosphorus source, and use NH 4 h 2 PO 4 To supplement the phosphorus source, LiOH·H 2 O and Li 2 CO3 As a combined lithium source, iron phosphorus Fe 1.5 P, NH 4 h 2 PO 4 , LiOH·H 2 O and Li 2 CO 3 The ratio of the amount of the substance is 2:1:1:1. After adding industrial ethanol to disperse into a rheological phase, put it in a muffle furnace at 300°C for pretreatment for 5 hours, and transfer it to a ceramic tube furnace at 700°C for roasting after cooling. 15h, using the raw material and oxygen in the air as the oxygen source, supplying oxygen in a diffuse manner, and obtaining black LiFePO after cooling 4 , whose crystal structure is attached figure 1 shown...

Embodiment 2

[0028] Fe 2.2 P as raw material to prepare LiFePO 4 As the positive electrode material, first crush ferrophosphorus to a certain particle size, use ferrophosphorus powder as the source of iron and phosphorus, and use NH 4 h 2 PO 4 To supplement the phosphorus source, LiOH·H 2 O and Li 2 CO 3 As a combined lithium source, iron phosphorus Fe 2.2 P, NH 4 h 2 PO 4 , LiOH·H 2 O and Li 2 CO 3 The ratio of the amount of the substance is 2:1:1:1, after adding industrial ethanol to disperse into a rheological phase, put it into a muffle furnace at 600°C for full oxidation treatment, after cooling, a certain amount of carbon is mixed into the precursor powder, and then transfer Put it into a quartz tube furnace at 750 ° C for 15 hours, use the raw material and oxygen in the air as the oxygen source, adopt the method of concentrated oxygen supply first, and then gradually reduce it, and obtain black LiFePO after cooling. 4 , the overall reaction equation is as follows:

[0...

Embodiment 3

[0034] The by-product phosphorus iron Fe of the yellow phosphorus production plant is recovered by reaction pulverization 2 P as raw material to prepare LiFePO 4 Cathode material, with phosphorus iron powder as phosphorus source and iron source, with Li 3 PO 4 As lithium source and supplementary phosphorus source, insufficient P is replaced by P 2 o 5 Supplement, the material ratio of the three is 6:4:1, a certain amount of oxygen is passed into the ball mill tank, after ball milling for 5 to 20 hours, it is put into a controlled atmosphere tube furnace at 700°C for 0.5 to 20 hours of roasting. 5 hours, control a certain air flow, use the raw material, oxygen and oxygen in the air as the oxygen source, and make black LiFePO 4 Electrode material, its morphology is as attached image 3 As shown, the reaction equation is as follows:

[0035] 12Fe 2 P+8Li 3 PO 4 +2P 2 o 5 +27O 2 →24LiFePO 4

[0036] No other by-products are produced during the reaction, and the morph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com