Sterile filling valve

An aseptic filling and filling machine technology, which is applied in the field of aseptic filling valve and aseptic cold filling process of beverages, can solve the problems of poor material passage, increased equipment cost, sanitary dead angle, etc. Simplified structure, guaranteed aseptic state, and smooth material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

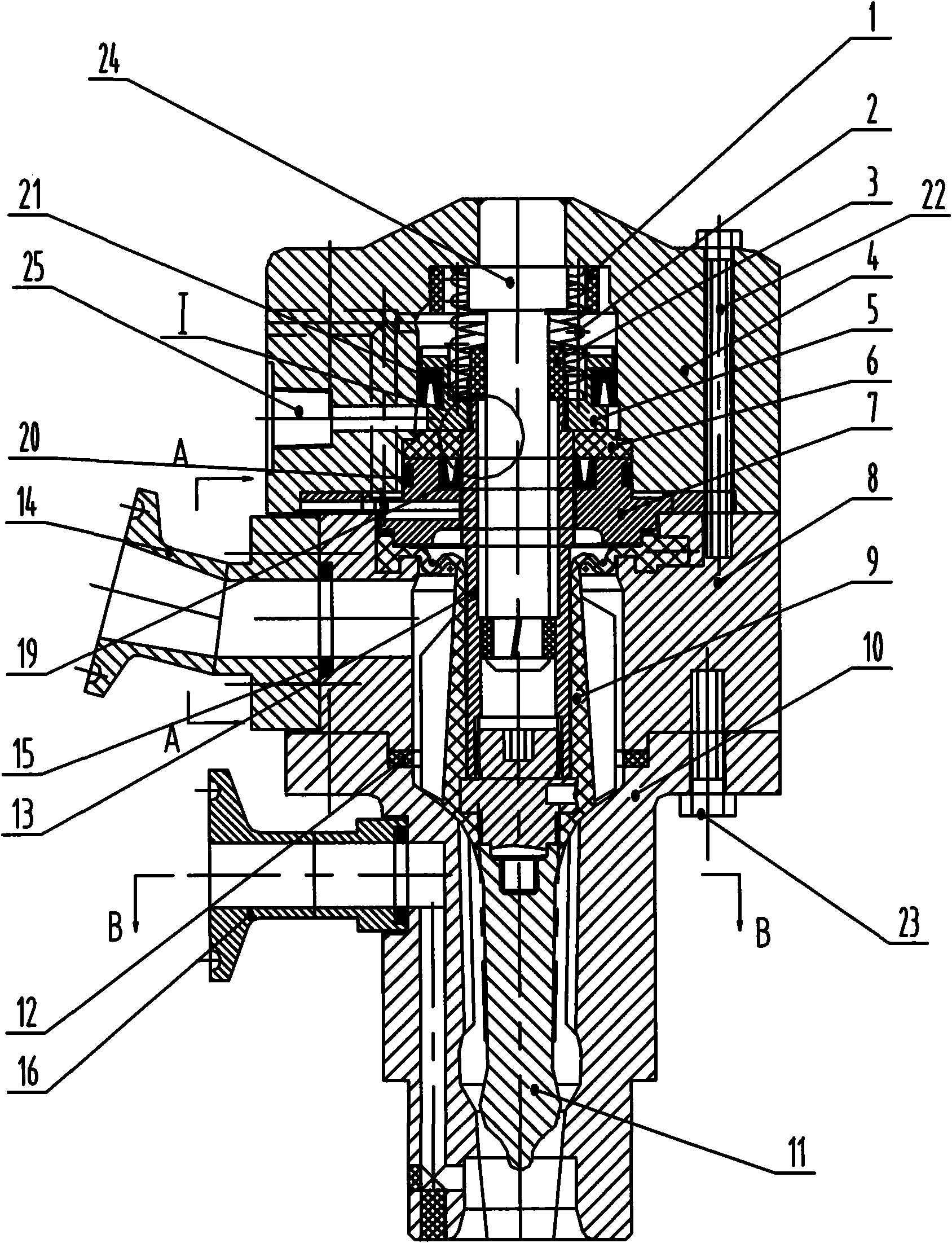

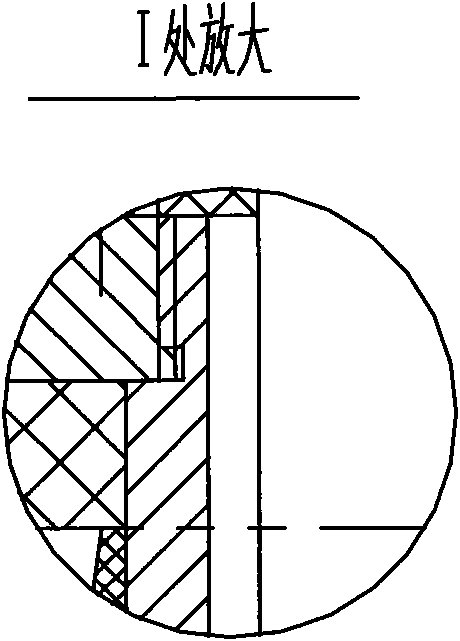

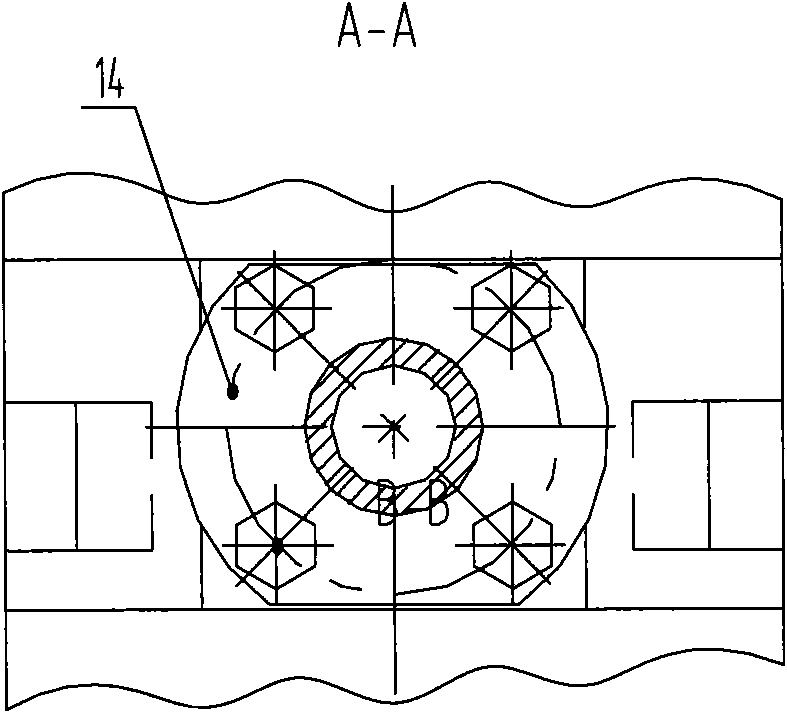

[0047] As shown in Figure 1, the aseptic filling valve is mainly composed of three parts: the upper valve seat 4, the lower valve seat 8 and the diversion sleeve 10. Inside the upper valve seat 4 is the opening and closing valve mechanism. The buffer ring 1 can play the role of buffering and anti-collision when the control gas is connected to open the filling valve; the spring 2 is compressed when the valve is opened. When the control gas is cut off, the spring 2 Reset to form a closed valve; the connecting sleeve 5 and the guide sleeve 13 are movable parts, so they need to be sealed with pneumatic U-rings 19 and 21. In order to facilitate the replacement of the pneumatic U-rings 19 and 21, the connecting sleeve 5 is designed as In the form of threaded connection, it is only necessary to unscrew the bolt 22, unscrew the connecting sleeve 5 and the guide sleeve 13 to replace it conveniently, without involving the gas-liquid separation membrane 9, so as to ensure that the gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com