Multi-functional chemical engineering experiment device

An experimental device and multi-functional technology, applied in the field of experimental instruments, can solve problems such as incomplete sets of instruments and equipment, poor environmental protection effect, and complicated connections, and achieve the effects of easy observation, compact structure, and simple installation and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

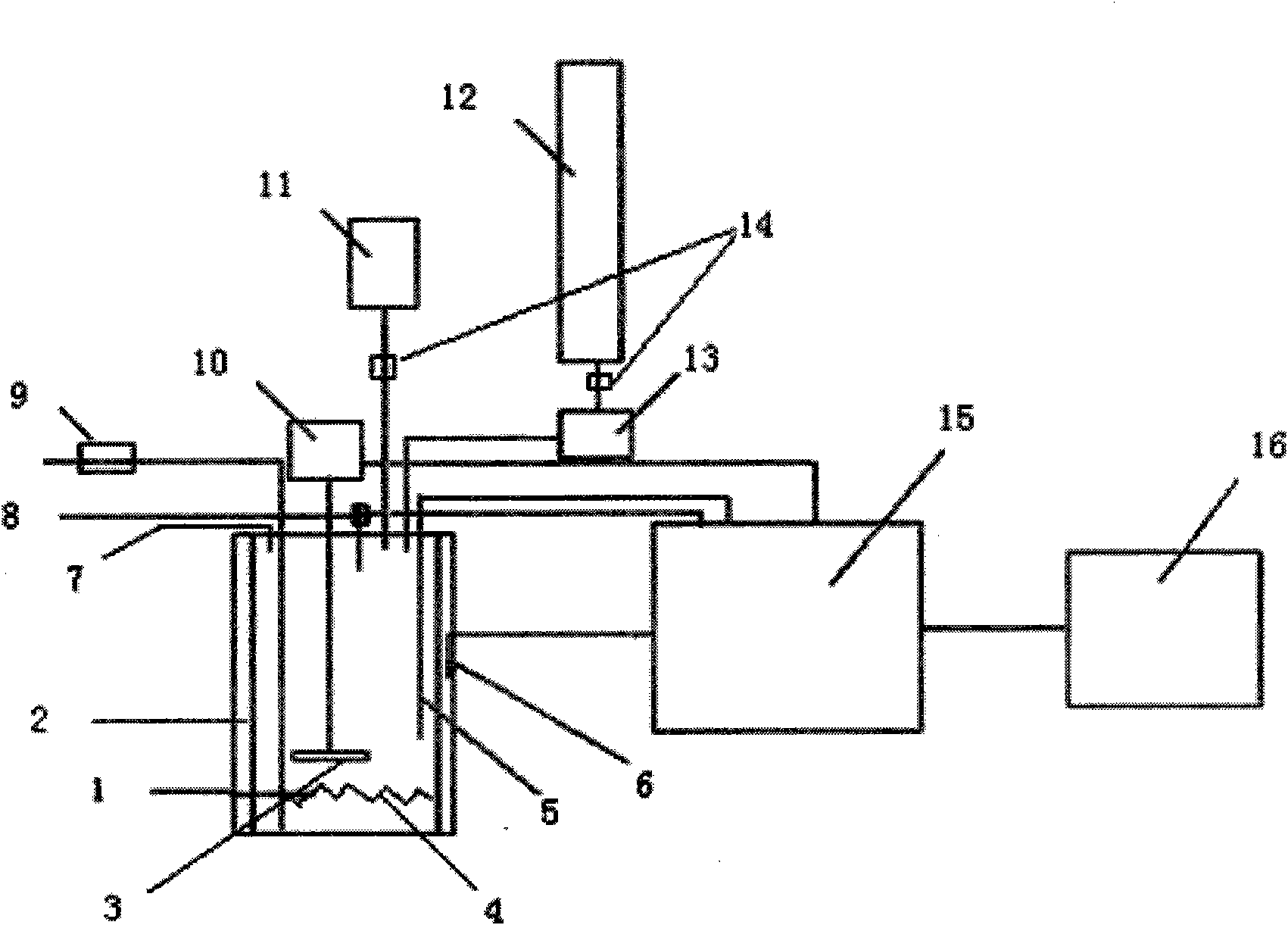

[0028] as attached figure 1 The schematic structural diagram of the embodiment of the present invention shown includes a chemical reactor, a reactor control system, a reaction material inlet and outlet, and a metering system.

[0029] Chemical reaction kettle 1 and vacuum system 7, internal pressure measurement and transmission device 8, motor speed measurement and transmission device 10, reflux separation and metering system consists of reflux condenser 12, sight glass 14, liquid separator 13 and liquid level Displays device connections. Reactor 1 has a volume of 1 liter, design pressure of 0.5Mpa, design temperature of 0°C-320°C, stirring speed: 0-1000rpm stepless speed regulation, heating power of 1.2KW, temperature control accuracy: ±0.5°C. The reactants are phthalic anhydride and n-butanol. Add phthalic anhydride, n-butanol and concentrated sulfuric acid into the reaction kettle, start stirring, set the temperature in the kettle to 120°C, the jacket temperature to 180°C,...

Embodiment 2

[0031] as attached figure 1 The schematic structural diagram of the embodiment of the present invention shown includes a chemical reactor, a reactor control system, a reaction material inlet and outlet, and a metering system.

[0032] The chemical reaction kettle 1 is connected with the vacuum system 7, the pressure measurement and transmission device 8 in the kettle, the motor speed measurement and transmission device 10, and the gaseous reactant feeding and metering system by a mass flow meter 9 device. Reactor 1 has a volume of 2 liters, a design pressure of 0.5Mpa, a design temperature of 0°C-320°C, a stirring speed of 0-1000rpm stepless speed regulation, a heating power of 2.2KW, and a temperature control accuracy of ±0.5°C. The reactants are p-cresol and isobutylene. Add methylphenol and concentrated sulfuric acid into the reaction kettle, start stirring, set the temperature in the kettle to 65°C, and the jacket temperature to 110°C. After the temperature rises to 50°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com