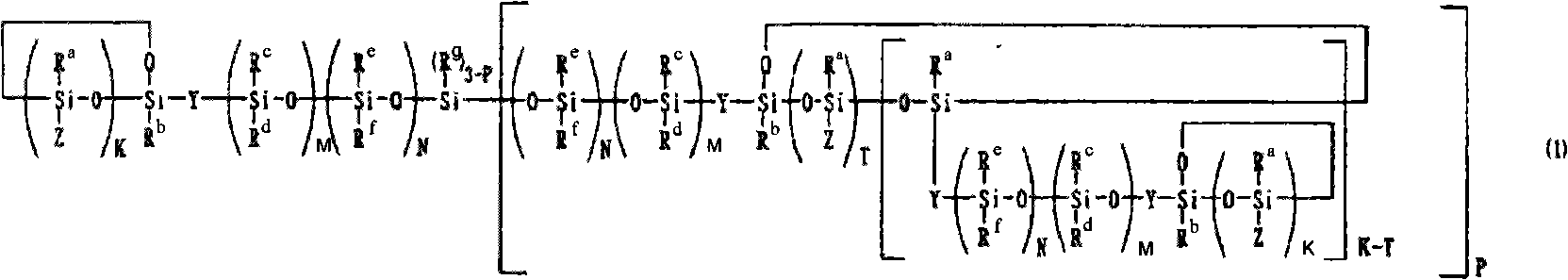

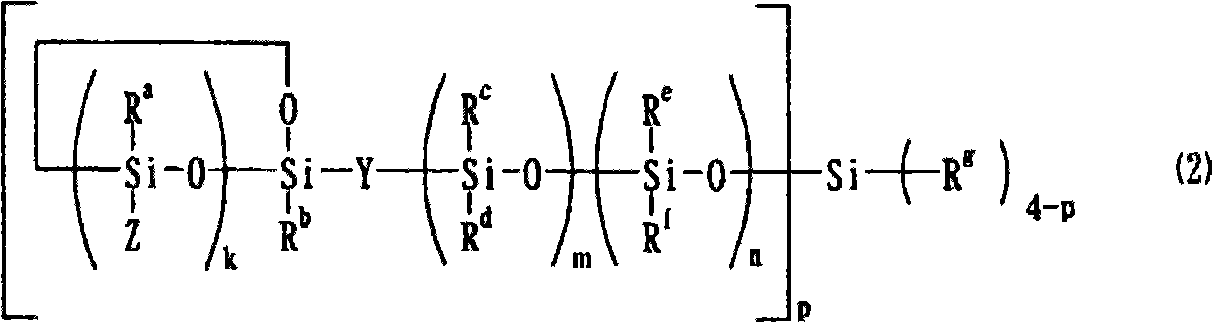

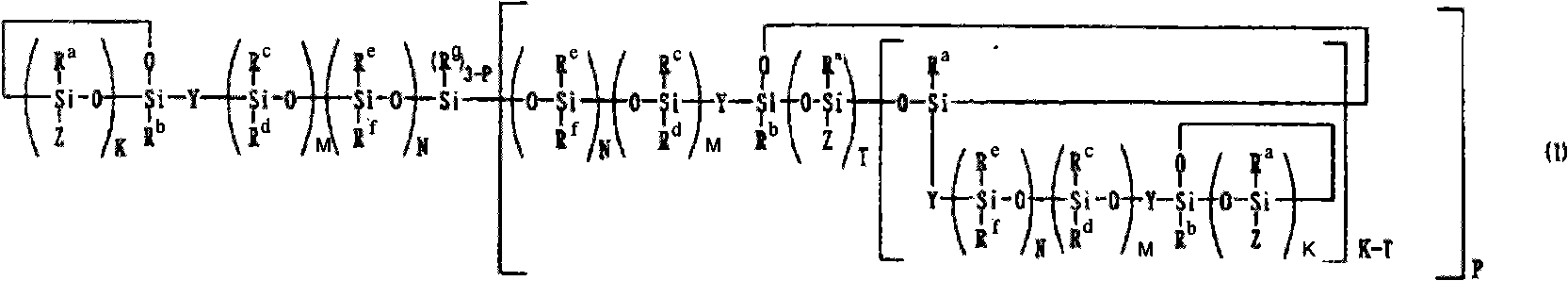

Silicon-containing compound, curable composition and cured product

A technology of curable composition and silicon compound, applied in the field of silicon-containing compound, curable composition and cured product, can solve the problem that curing characteristics may not be sufficient and cured product cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Hereinafter, the present invention will be described in more detail with examples and the like, but the present invention is not limited to these examples and the like. In addition, "part" and "%" in an Example are based on mass.

Synthetic example 1

[0081] Mix 90 parts of dichlorodimethylsilane and 9 parts of dichlorodiphenylsilane, and add dropwise to a mixture of 100 parts of ion-exchanged water, 50 parts of toluene and 450 parts of 48% aqueous sodium hydroxide solution at 105 Polymerization was carried out at °C for 5 hours. After washing the obtained reaction solution with 500 parts of ion-exchanged water, the toluene solution was dehydrated, 20 parts of pyridine was added, and 20 parts of dimethylvinylchlorosilane was added thereto, followed by stirring at 70° C. for 30 minutes. Then, after washing with 100 parts of ion-exchanged water, the solvent was distilled off under reduced pressure at 150°C. Next, after washing with 100 parts of acetonitrile, the solvent was distilled off under reduced pressure at 70° C. to obtain an acyclic polysiloxane compound (a1-1) having an unsaturated bond. As a result of analysis by GPC under the following conditions, the molecular weight Mw of the acyclic polysiloxane compound (a1-1)...

Embodiment 1

[0086] Dissolve 100 parts of the acyclic polysiloxane compound (a1-1) having an unsaturated bond obtained in Synthesis Example 1 in 200 parts of toluene, add 0.003 parts of a platinum catalyst, and as a cyclic polysiloxane compound 10 parts of 1,3,5,7-tetramethylcyclotetrasiloxane were reacted at 105°C for 2 hours. After the solvent was distilled under reduced pressure at 70°C, it was washed with 100 parts of acetonitrile. Then, the solvent was distilled under reduced pressure at 70°C to obtain a silicon-containing compound (A-1). As a result of analysis by GPC, the molecular weight Mw of the silicon-containing compound (A-1) was 22,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com