Large single crystal diamonds

A single crystal diamond and diamond technology, applied in the field of diamond material preparation, can solve the problems of high cost and complicated methods, and achieve the effect of improving spatial uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188] A set of 40 seeds prepared from HPHT diamond was selected. The seed has a polished upper (growth) surface (R measured using a stylus profilometer of less than 100 nm a ) and laser cutting from larger sheets using a Nd:YAG laser. The seeds had dimensions of 5.0mm x 0.58mm x 0.58mm. The geometry of the seed was such that the growth surface was within 10° of (001) and the seed edge was within 10° of the direction.

[0189] Select seeds based on the following criteria:

[0190] ●Inclusion content (no inclusions with a size greater than 0.2mm, and an average of less than 1 inclusion per linear millimeter of the maximum edge length)

[0191] ●No cracks (observed under 10×)

[0192] ●Surface finish (R a <80nm)

[0193] ●>60% single sector growth habit

[0194] • Dimension Tolerance - All dimensions are within 0.1mm of the required dimensions.

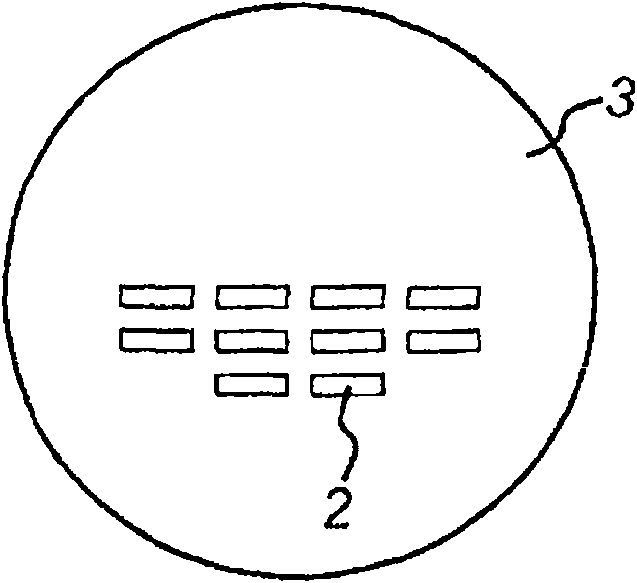

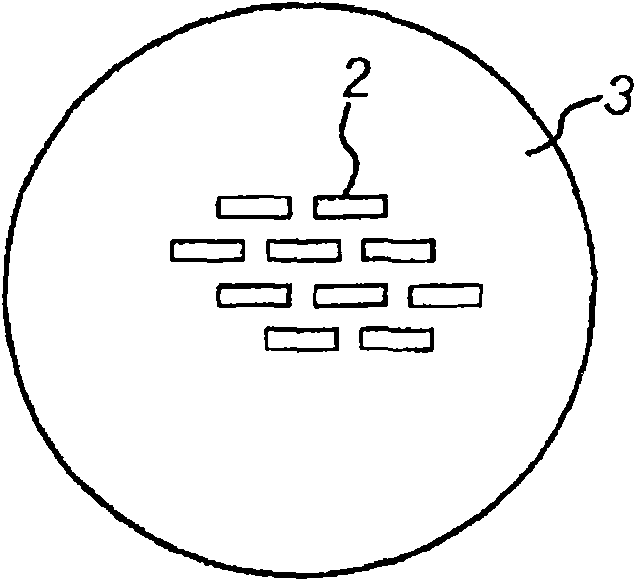

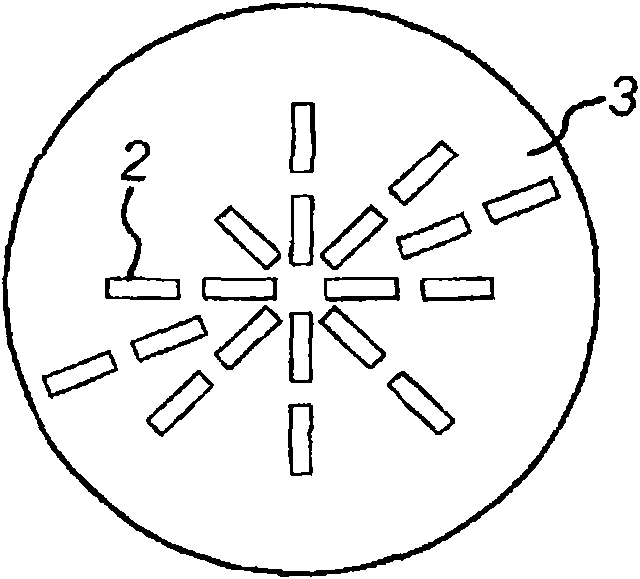

[0195] use as Figure 1a The layout shown has the seeds arranged on a seed carrier with a spacing of 5.75mm between the seed...

Embodiment 2

[0204] A set of 59 seeds prepared from HPHT diamond was selected. The seed has a polished upper (growth) surface (R measured with a stylus profilometer of less than 100 nm a ) and laser cut from larger sheets using a Nd:YAG laser. The seed has dimensions of 3.5 mm x 1.0 mm x 1.0 mm. The geometry of the seed was such that the growth surface was within 10° of (001), and the edge of the seed was within 10° of the direction.

[0205] Select seeds based on the following criteria:

[0206] ●Inclusion content (no inclusions with a size greater than 0.2mm, and an average of less than 1 inclusion per linear millimeter of the maximum edge length)

[0207] ●No cracks (observed at 10× magnification)

[0208] ●Surface finish (Ra <80nm)

[0209] ●>60% single sector growth habit

[0210] • Dimension Tolerance - All dimensions are within 0.1mm of the required dimensions.

[0211] use as Figure 1a The layout shown arranges the seeds on a seed carrier with about 5.75mm spacing between...

Embodiment 3

[0224] A set of 34 seeds prepared from HPHT diamond was selected. The seed has a polished upper (growth) surface (R measured with a stylus profilometer of less than 100 nm a ) and laser cut from larger sheets using a Nd:YAG laser. The seed crystal has dimensions of 7.0 mm x 1.0 mm x 1.0 mm. The geometry of the seed was such that the growth surface was within 10° of (001), and the edge of the seed was within 10° of the direction.

[0225] Select seeds based on the following criteria:

[0226] ●Inclusion content (no inclusions with a size greater than 0.2mm, and an average of less than 1 inclusion per linear millimeter of the maximum edge length)

[0227] ●No cracks (observed at 10× magnification)

[0228] ●Surface finish (R a <80nm)

[0229] ●>60% single sector growth habit

[0230] • Dimension Tolerance - All dimensions are within 0.1mm of the required dimensions.

[0231] use as Figure 1a The layout shown arranges the seeds on a seed carrier with about 5.75mm spaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

| Scale | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com