Wooden package temperature real-time detector

A real-time detection and packaging technology, applied to thermometers, instruments, thermometers with direct heat-sensitive electric/magnetic elements, etc., can solve the problems of dispersion, long distance, heavy workload of measuring personnel, complete accuracy, etc., to achieve accurate Acquisition and transmission, scientific and reasonable structural design, to achieve the effect of acquisition and transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

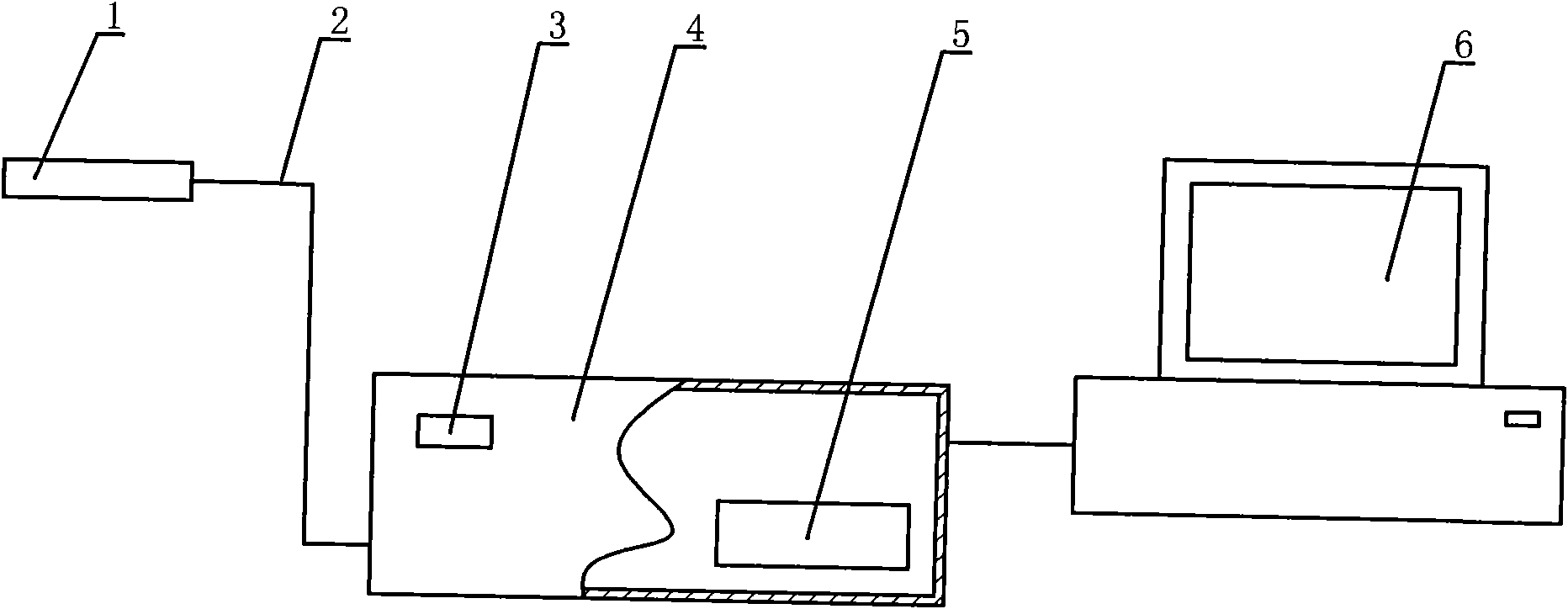

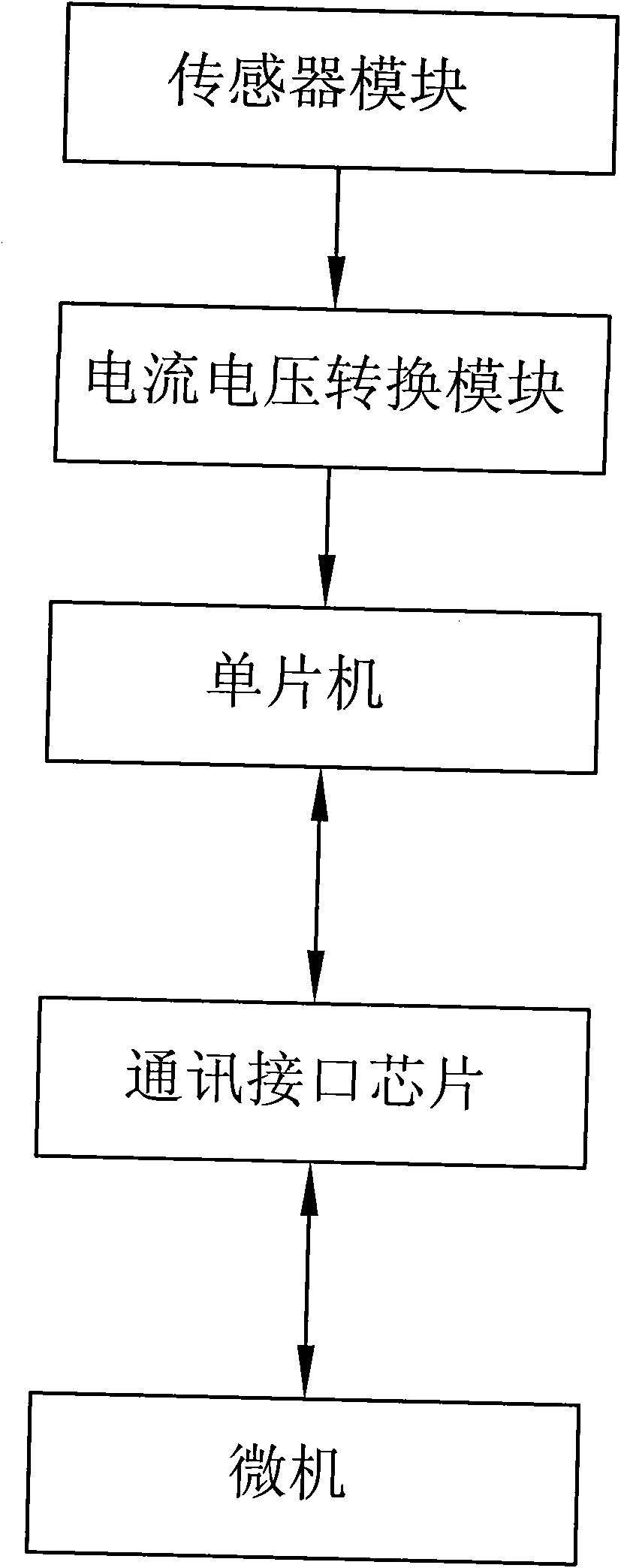

[0019] A wooden packaging temperature real-time detector, which is composed of a temperature measuring sensor 1, a housing 4 and a control circuit 5 installed in it, wherein a switch 3 is arranged on the front of the housing, and the temperature measuring sensor is connected to the control circuit in the housing through a cable 2, The temperature sensor uses high-precision platinum resistance as the front-end probe. The sensing range of the probe can reach -200°C-600°C, and the temperature coefficient TCR=3850ppm / °C. The sensor module is used to adjust the measurement range and linearize the signal to make the output The electrical signal has a good linear relationship with the actual temperature value wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com