Ceramic antique bricks taking construction waste stone powder as raw material and preparation method thereof

A technology for waste stone powder and antique bricks is applied in the field of decorative materials, which can solve the problems of affecting the appearance, easy cracking or deformation, high calcium content and silicon content, and achieve the effect of saving raw materials and reducing process costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

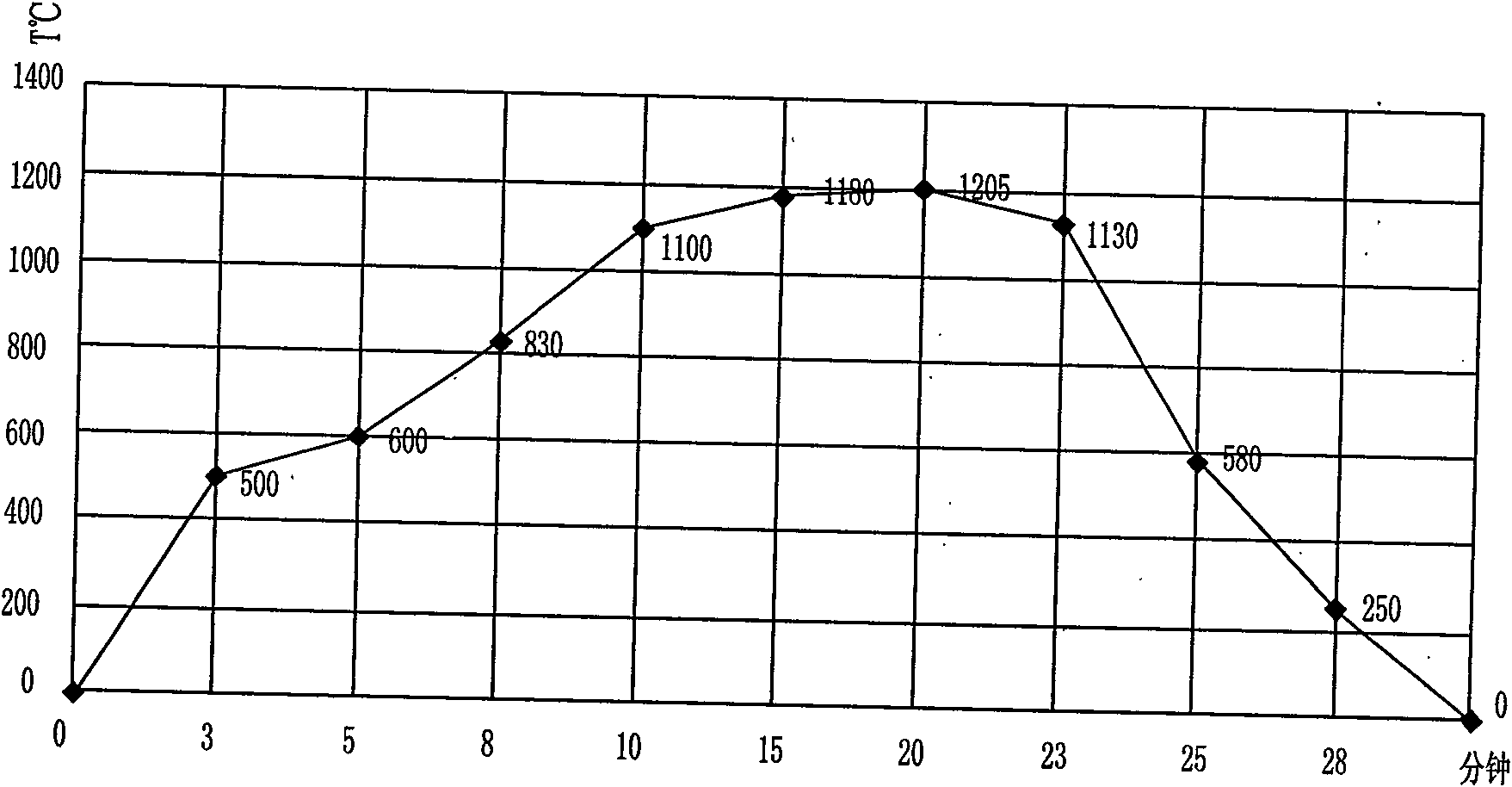

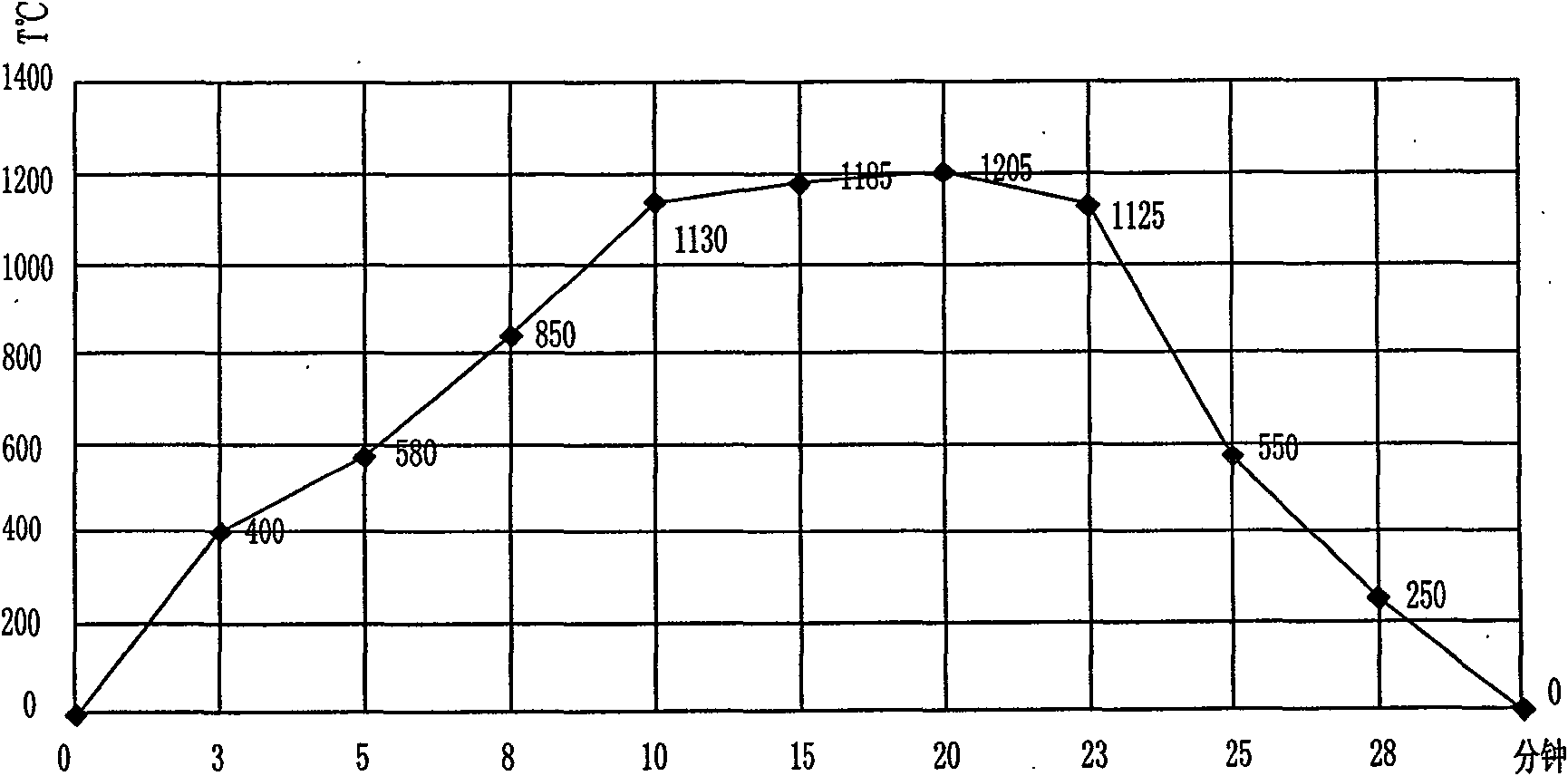

[0023] Such as figure 1 , image 3 Shown, a kind of ceramic archaize brick that utilizes construction waste stone powder as raw material of the present invention, it is to utilize construction waste stone powder to replace the original high-quality stone powder of natural exploitation of ceramic industry, and its mineral raw material formula is preferred (by weight percentage): waste stone 20%, stone powder 10%, sand 29%, high alumina mud 35%, talcum powder 2.5%, waste 3.5%. The chemical composition of the waste stone is calculated by weight percentage, including SiO 2 78%, Al 2 o 3 13.2%, Fe 2 o 3 1.18%, TiO 2 0.35%, CaO 1.23%, MgO 0.23%, K2O 4.23%, Na2O 0.09%, IL 2.49%.

[0024] The main technical indicators are

[0025] ①Rupture modulus: above 24.5Mpa;

[0026] ②Water absorption: 6.0-9.0%;

[0027] ③Destruction strength: above 850N;

[0028] ④Pollution resistance: level 5;

[0029] ⑤ Resistance to household chemical reagents: GA grade;

[0030] ⑥Swimming po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com