Biomass gasifier

A gasifier and biomass technology, applied in the field of gasifiers, can solve the problems of no continuous ash discharge, blockage of through-holes, material leakage, etc., and achieve a process that is conducive to smooth reaction, improved work efficiency, and increased gas production capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

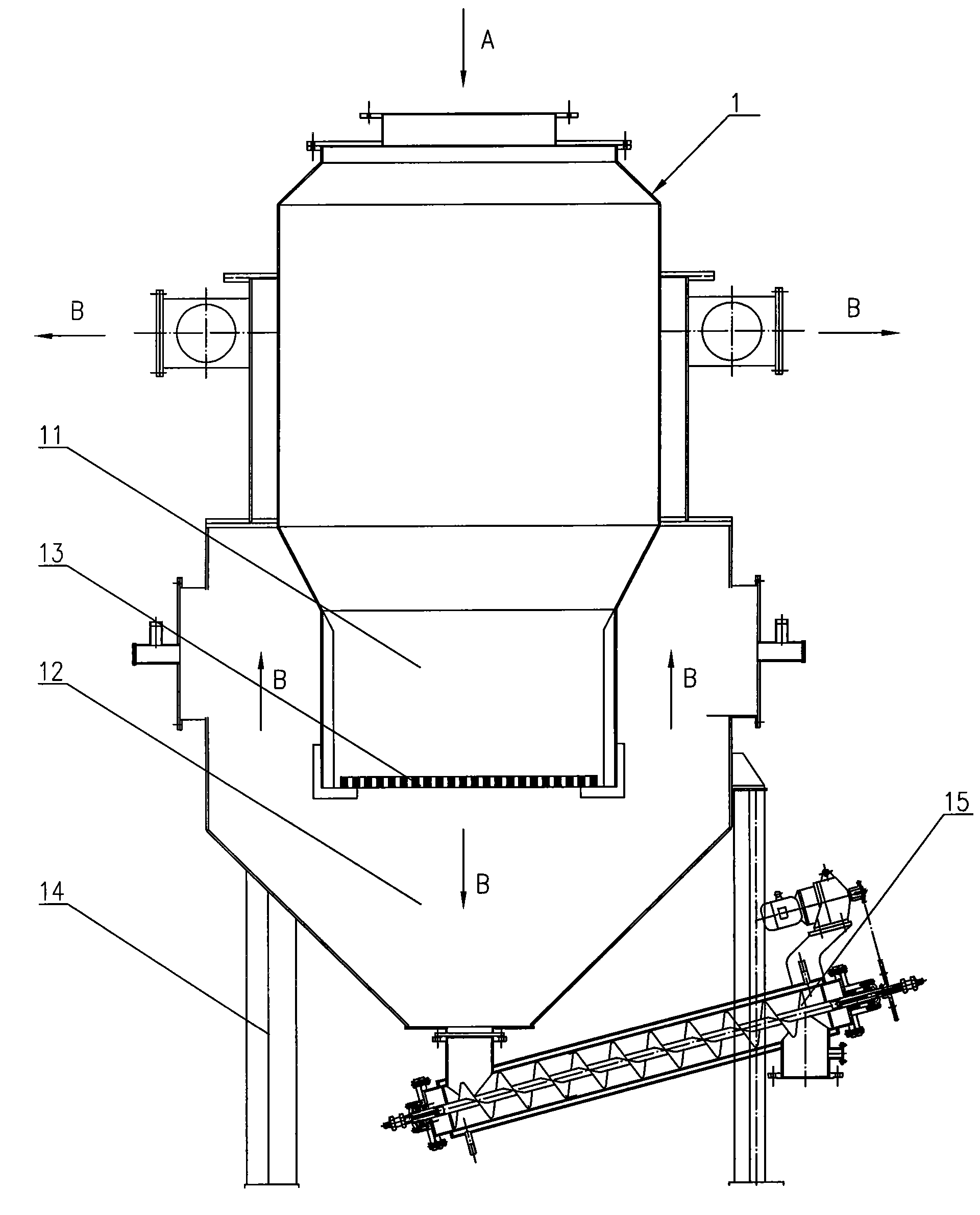

[0042] Such as figure 2 As shown, in the present embodiment, the biomass raw material adopts chaff, and a biomass gasification furnace 1 of the present invention includes a furnace body 11, a grate 13, an ash chamber 12, a support 14 for supporting the gasification furnace 1, and a row The ash mechanism, the grate 13 is made of alloy steel, the surface is covered with heat-insulating material, the heat-insulating material is made of refractory cement, the grate 13 is horizontally arranged in the furnace body 11, the ash chamber 12 is located below the furnace body 11, and the grate 13 is in the middle Non-porous flat plate structure, the ash discharge hole 2 is set along the edge where the grate 13 meets the inner wall of the furnace body 11, the outer contour of the grate 13 is smaller than the inner wall of the furnace body 11, and its outer edge is in line with the furnace body 11 The ash discharge hole 2 is formed by the annular gap between the inner walls.

[0043] On t...

Embodiment 2

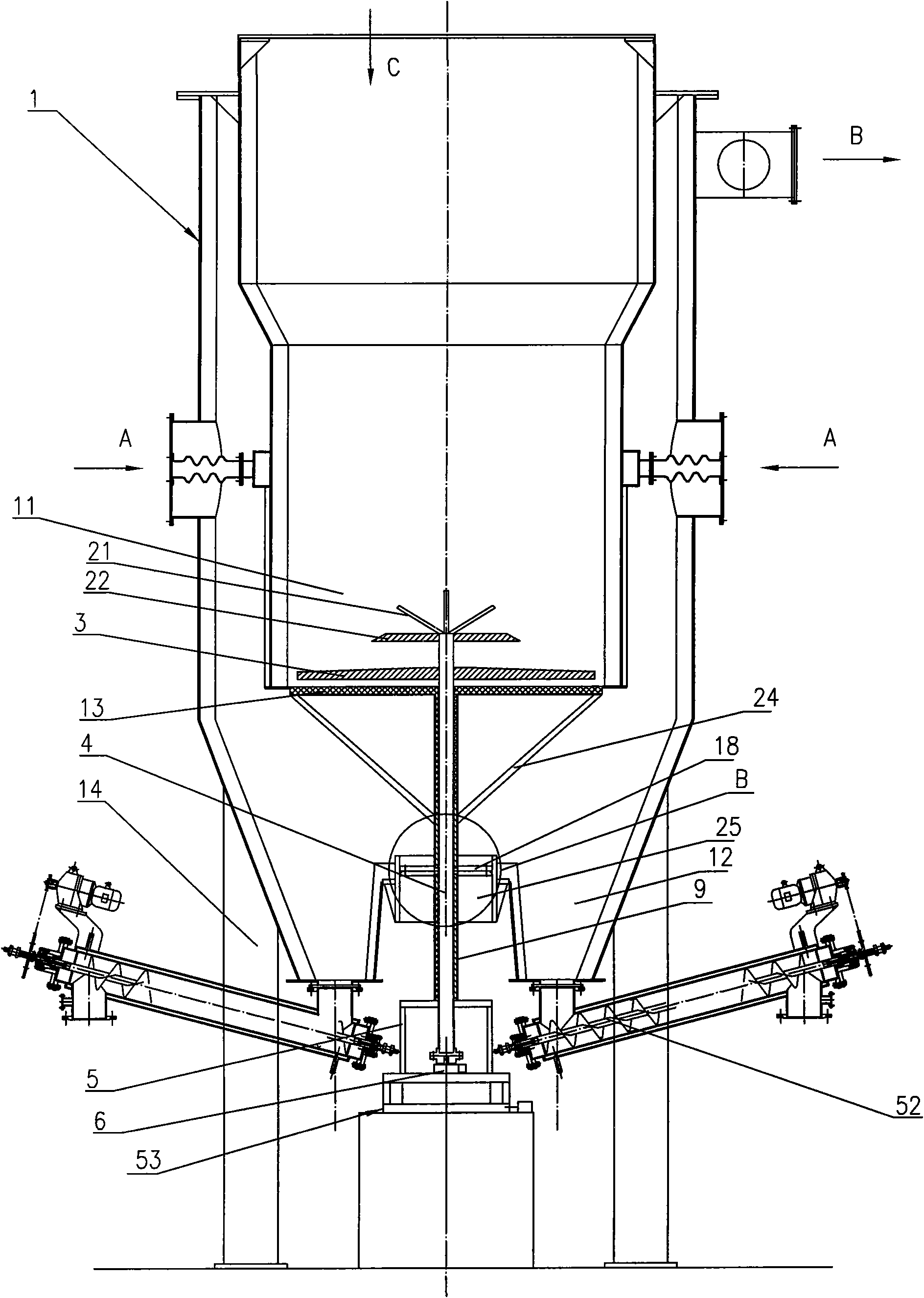

[0051] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the biomass raw material adopts pulverized coal, the material of the grate 13 is alloy cast iron, and a grate installation shaft 9 extending downward is added to the central part of the grate 13, and the furnace grate The grid installation shaft 9 is a sleeve-type structure and is sleeved on the shaft 4 of the dust-pushing stick, and is installed on the shield 5 through the cylindrical installation hole 25 at the bottom of the ash chamber 12, between the grate 13 and the grate installation shaft 9 There are several support ribs 24 for supporting the rod-shaped structure of the grate 13, the shield 5 is located outside the lower part of the ash chamber 12, and a chuck is set on the grate installation shaft 9. In this embodiment, the chuck The plate adopts two flanges 18. When disassembly or installation is required, the upper part of the grate 13 with the grate installation shaft 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com