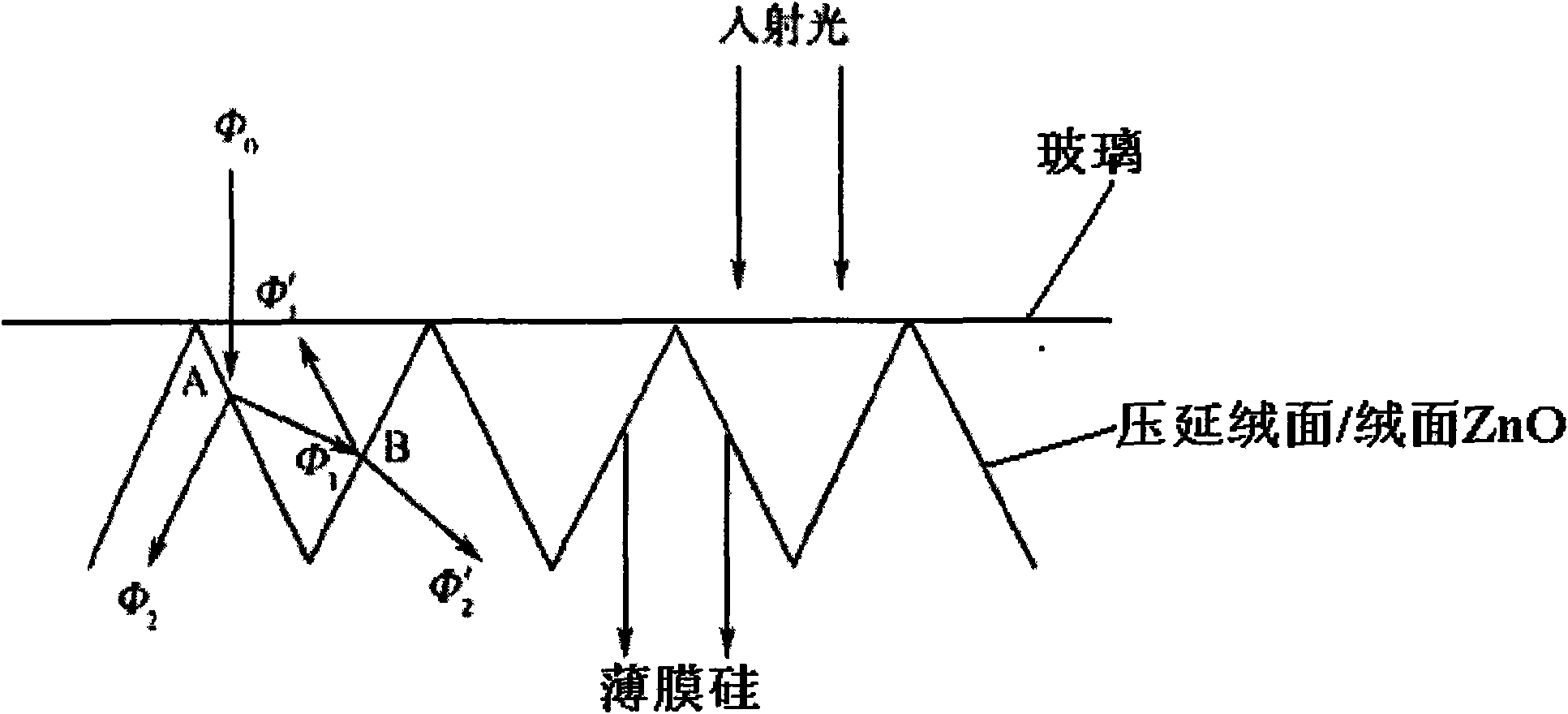

Method for preparing textured ZnO transparent conductive coated glass

A coated glass, transparent and conductive technology, applied in the field of thin film solar photovoltaic cells and building integrated photovoltaics, glass processing, can solve the problems of reducing the performance of silicon thin film solar photovoltaic cells, toxic FTO films, air pollution, etc., to reduce complexity, Effect of avoiding pollution and increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: High-purity argon is used as the working gas for sputtering coating.

[0024] 1) At first, the suede glass substrate to be coated is cleaned and dried;

[0025] 2) Put the dry and clean suede glass substrate on the back and the vacuum is ≤2.5×10 -3 pa vacuum chamber.

[0026] 3) Under the high-purity argon atmosphere of 0.35Pa, SiO with a film thickness of 30nm is coated on the suede surface of the substrate glass 2 Isolate the transition layer.

[0027] 4) Under the high-purity argon atmosphere of 0.35Pa, in SiO 2 The ZnO thin film is sputtered on the isolation transition layer; or the ZnO thin film is directly deposited on the suede surface of the glass by magnetron sputtering.

[0028] The properties of the obtained textured ZnO transparent conductive coated glass are as follows: the thickness of the textured ZnO film is 450nm, the total visible light transmittance is 87%, the texture is 38%, and the sheet resistance is 19.8Ω / □.

Embodiment 2

[0029] Embodiment 2: High-purity argon is used as the working gas for sputtering coating.

[0030] 1) at first the suede glass substrate to be coated is cleaned and dried;

[0031] 2) Put the dry and clean suede glass substrate on the back and the vacuum is ≤2.5×10 -3 Pa's vacuum chamber.

[0032] 3) In a high-purity argon atmosphere of 0.35Pa, coat SiO on the suede surface of the substrate glass 2 The transition layer is isolated with a film thickness of 40nm.

[0033] 4) In a high-purity argon environment of 0.40Pa, the SiO 2 The ZnO thin film is sputtered on the isolation transition layer; or the ZnO thin film is directly deposited on the suede surface of the glass by magnetron sputtering.

[0034] The properties of the obtained textured ZnO transparent conductive coated glass are as follows: the thickness of the textured ZnO film is 550nm, the total visible light transmittance is 85%, the texture is 35%, and the sheet resistance is 17.2Ω / □.

Embodiment 3

[0035] Embodiment 3: High-purity argon is used as the working gas for sputtering coating.

[0036] 1) at first the suede glass substrate to be coated is cleaned and dried;

[0037] 2) Put the dry and clean suede glass substrate on the back and the vacuum is ≤2.5×10 -3 pa vacuum chamber.

[0038] 3) In a high-purity argon atmosphere of 0.40Pa, coat SiO on the suede surface of the substrate glass 2 Isolate the transition layer with a film thickness of 50nm.

[0039] 4) In the high-purity argon environment of 0.45Pa, the SiO 2The ZnO thin film is sputtered on the isolation transition layer; or the ZnO thin film is directly deposited on the suede surface of the glass by magnetron sputtering.

[0040] The properties of the obtained textured ZnO transparent conductive coated glass are as follows: the thickness of the textured ZnO film is 650nm, the total transmittance of visible light is 84%, the texture is 32%, and the sheet resistance is 16Ω / □.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com