Circumferential direction mixer and gas-liquid/liquid-liquid mixing method using the same

A mixer, gas-liquid technology, applied in fluid mixers, chemical instruments and methods, mixers, etc., can solve problems such as not being able to withstand high temperature and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

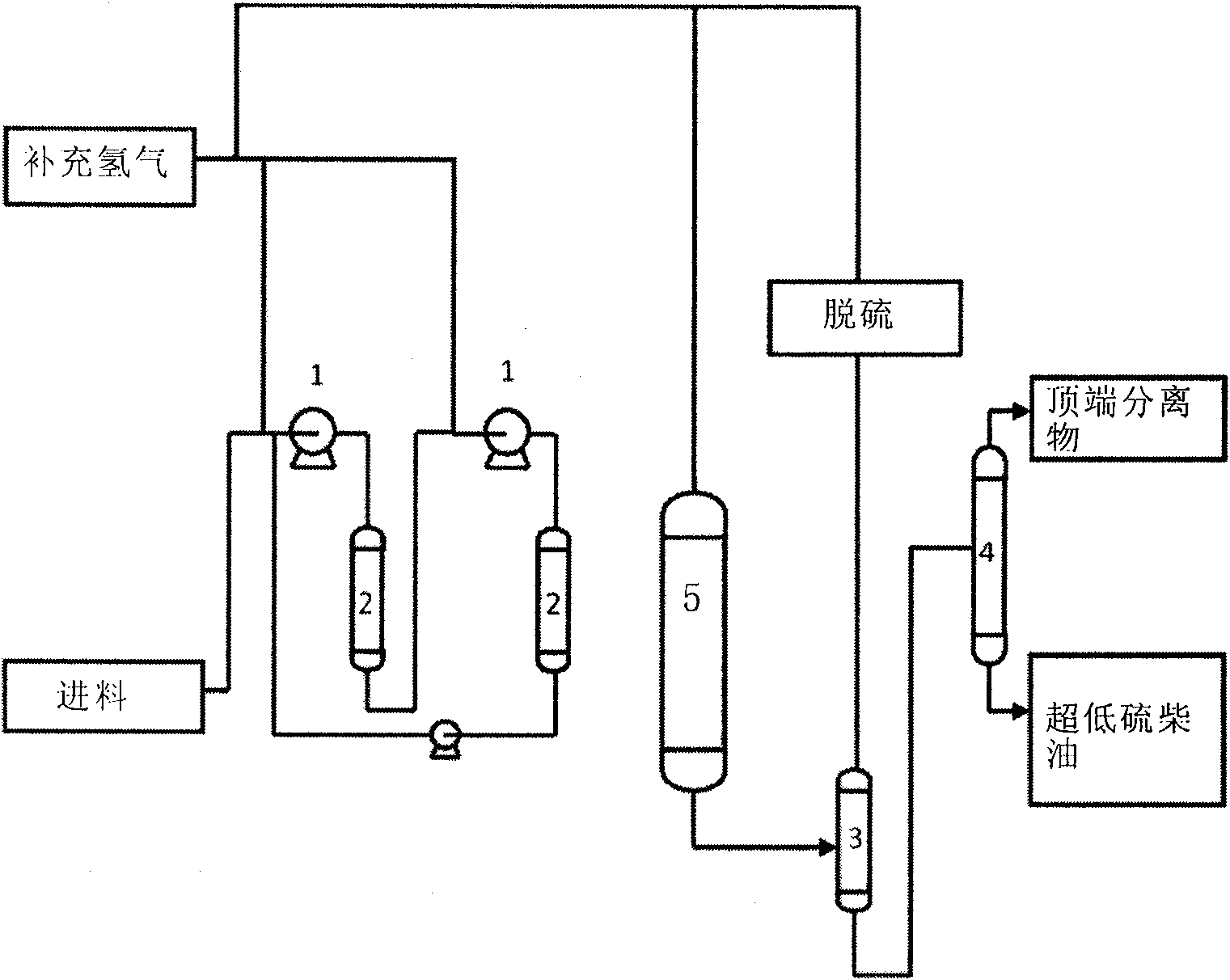

[0037] The peripheral mixer of the present invention is applied in the Isotherming technological process, as image 3 shown. The device capacity can reach 3800bbl / day, and meet the specification of 10ppmw sulfur content in diesel products. Its feedstock is similar to that of many refineries, a 60 / 40 mixture of straight run distillate and LCO, with a sulfur content of about 2,100 ppmw.

[0038] In this process flow, raw oil and supplementary hydrogen are fed into the circumferential mixer at the same time, and the two are uniformly mixed by the function of the circumferential mixer, and at the same time circulated through the circulation pump, and the preliminary reaction is carried out through the Isotherming reactor, thereby improving the The mixing degree of the hydrogen-dissolved heavy oil entering the hydrogenation reactor.

[0039] As one of the ways to improve the effect of hydrogenation reaction, the device improves the reaction effect of hydrocracking, improves the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com