Mixing treatment system for recycling and reutilizing foundry sand

A mixed processing and casting technology, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, manufacturing tools, etc., can solve the problems of no cooling function, inconvenient use, low efficiency, etc., and reduce reuse cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

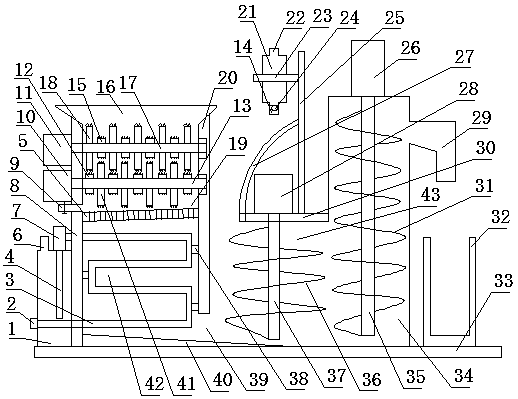

[0022] Such as figure 1 The casting molding sand recovery and reuse mixed treatment system shown includes a base plate 33, and the upper part of the base plate 33 is sequentially provided with a cooling water chamber 1, a cooling chamber 42, a mixing chamber 43, a lifting chamber 34, a molding sand collection frame 32, and a cooling chamber The upper part of 42 is provided with a crushing chamber 19, and the upper part of the crushing chamber 19 is provided with a feed port 16; the upper part of the cooling water chamber 1 is equipped with a water pump 7, and the outlet of the water pump 7 is connected to a U-shaped cooling water pipe 3, which is installed on the In the cooling chamber 42, the inlet of the water pump 7 is connected with the cooling water supply pipe 4, and the cooling water supply pipe 4 is arranged in the cooling water chamber 1; The first motor 11 and the second motor 10 are respectively connected to the left end of the second shaft 13, the first long crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com