Wastewater treatment device for numerical control system equipment

A technology for wastewater treatment and numerical control system, applied in the numerical control field, can solve problems such as low wastewater treatment efficiency, and achieve the effects of reducing standing time, increasing mixing effect and treatment efficiency, and improving treatment work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

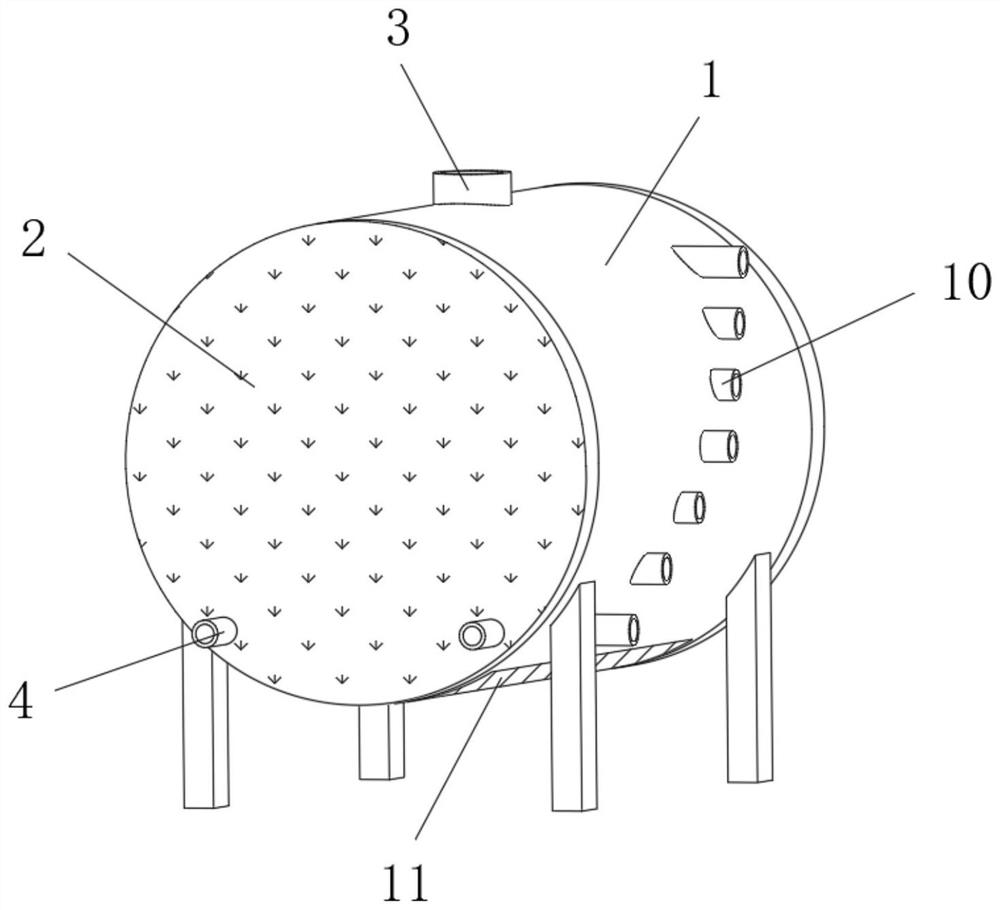

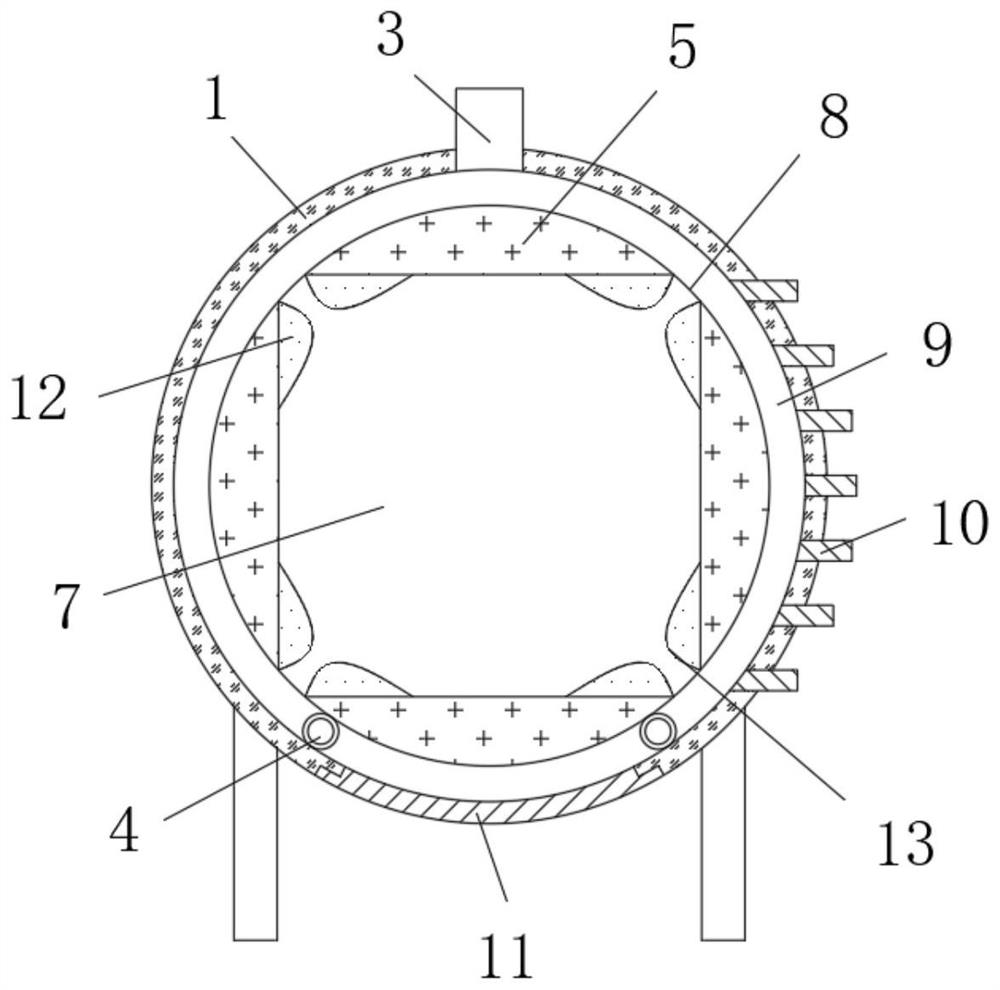

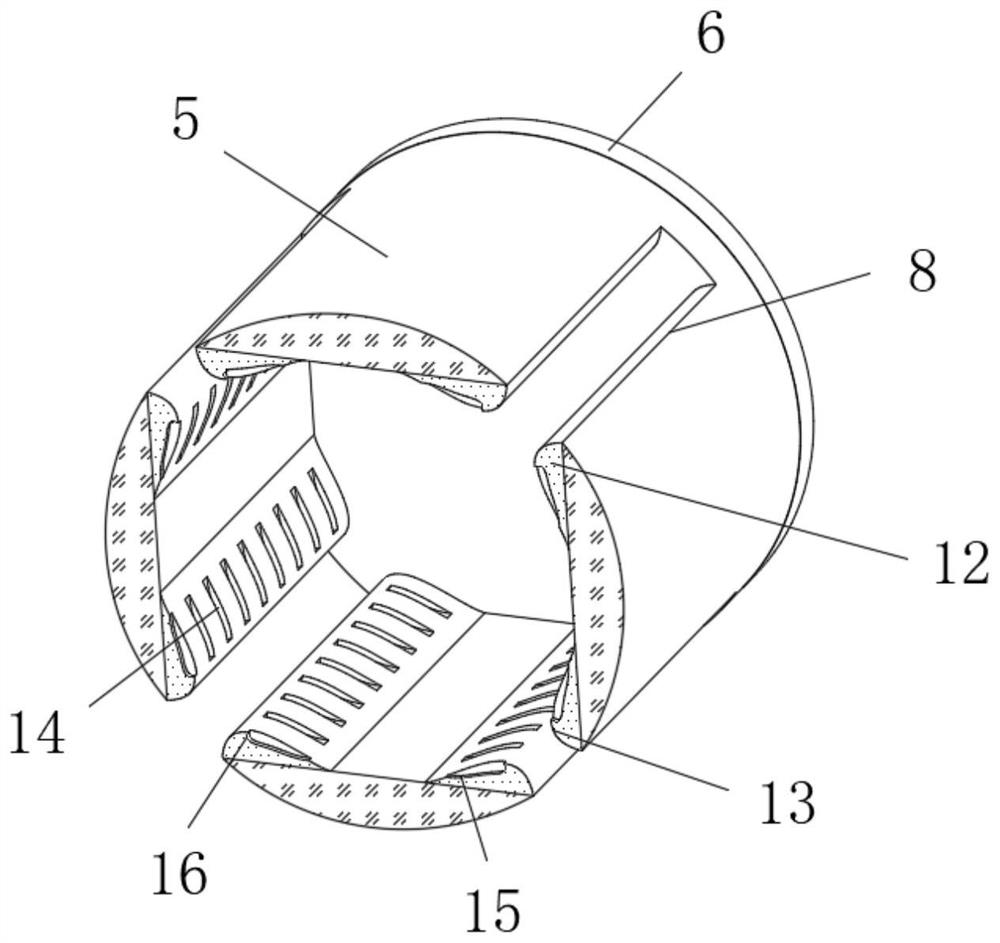

[0026] refer to Figure 1-3 , a wastewater treatment device for numerical control system equipment, comprising a treatment cylinder 1, the two ends of the treatment cylinder 1 are fixed with a sealing cover plate 2, the top and bottom of the treatment cylinder 1 are respectively fixed with a water inlet pipe 3 and an outlet pipe 4, A connecting piece 5 with a cylindrical structure is rotatably connected between the inner walls of the two ends of the processing cylinder 1, and one end of the connecting piece 5 is connected with a drive mechanism, and the two ends of the connecting piece 5 are fixed with a positioning ring 6, and the sealing cover plate 2 One end is provided with a positioning groove corresponding to the positioning ring 6, the inner wall of the positioning groove is rotatably connected with the outer wall of the positioning ring 6 through a bearing, and an auxiliary chamber 9 is formed between the circumferential outer wall of the connecting piece 5 and the circ...

Embodiment 2

[0032] refer to Figure 1-4 , a waste water treatment device for numerical control system equipment, the middle position between the inner walls of the two ends of the mixing chamber 7 is rotatably connected with a mounting part 17, and the peripheral outer wall of the mounting part 17 is fixed with multiple sets of guide vanes 18 along the The groups of guide vanes 18 are equidistantly distributed along the axial direction of the mounting part 17, and each group of guide vanes 18 is distributed in an annular array, and the outer walls on both sides of the guide vanes 18 are arranged in a streamlined structure. 17 is arranged as a hollow tubular structure, and a plurality of perforations 19 are opened on one side of the outer wall of the guide vane 18 .

[0033]During use, make relative movement between the guide vane 18 and the connecting part 5 of the installation part 17 of the mesh cylinder structure and its outer wall, to improve The mixing treatment effect in the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com