Plasma-processing device and method of manufacturing adhesion-preventing member

A plasma and processing device technology, applied in the direction of plasma, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as the impact of manufacturing yield, achieve the effects of reducing manufacturing cost, improving manufacturing yield, and suppressing characteristic changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

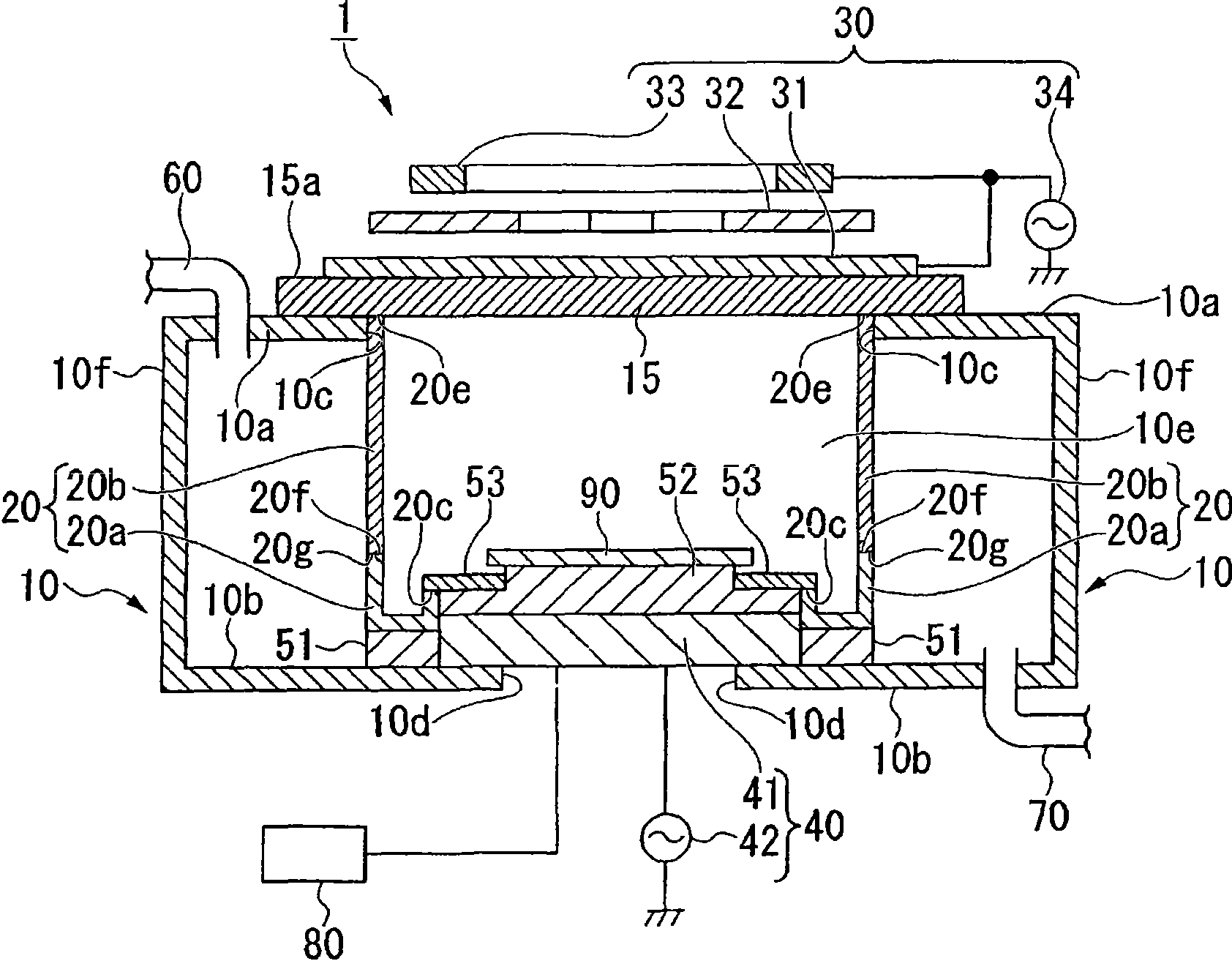

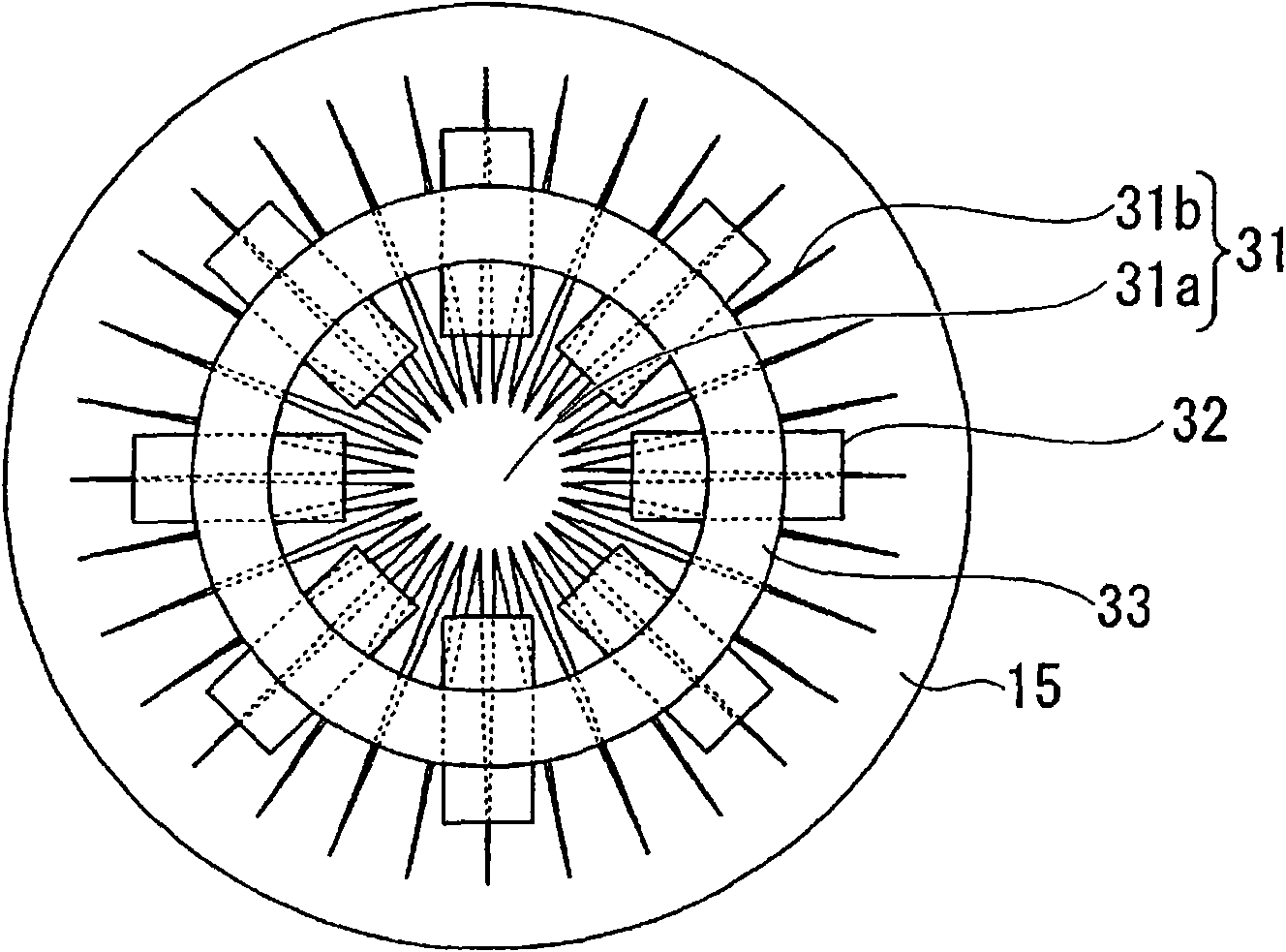

[0052] figure 1 It is a schematic configuration diagram of an etching apparatus (plasma processing apparatus) 1 of the present invention. The etching apparatus 1 has a processing chamber 10, an anti-adhesion member 20, a plasma generating device 30, a bias generating device 40, a first quartz plate 15, a heating device 51, a supporting member 52, a second quartz plate 53, an air intake device 60, Exhaust equipment 70 and cooling device 80 . The plasma generation device 30 has a first electrode 31 , a permanent magnet 32 , an antenna 33 and a first high-frequency power source 34 . The bias generating device has a second electrode 41 and a second high-frequency power source 42 .

[0053] The processing chamber 10 is formed in a cylindrical shape, has an opening 10c in the top wall 10a, and has an opening 10d in the bottom wall 10b. On the outside of the ceiling wall 10 a of the processing chamber 10 , a first quartz plate 15 is placed to cover the opening 10 c. A first ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com