Insulation layer for use in thermal insulation, insulation and method of manufacturing such

A technology for insulating layers and insulating parts, which is applied in the field of manufacturing insulating parts and can solve the problems of affecting vacuuming time, long production time, and reduced insulation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

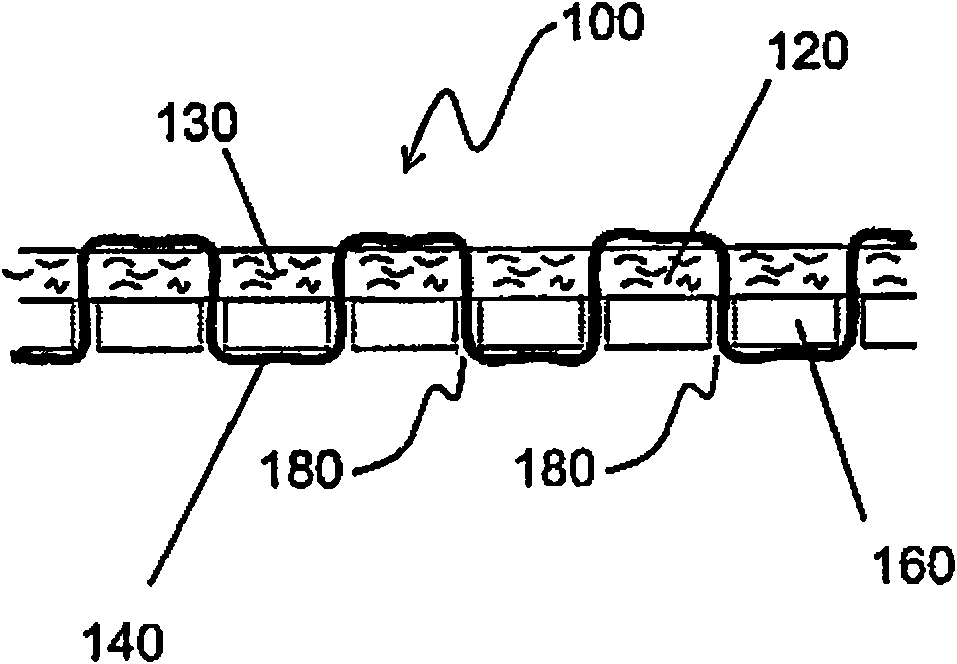

[0037] figure 2 An embodiment of an insulating layer 100 according to the invention is shown. The insulating layer 100 includes a radiation shield 160 for reflecting thermal radiation and an insulating material 120 . Radiation shield 160 is attached to isolation material 120 by fastening material 140 . A plurality of apertures 180 are provided on the radiation shield 160 . The insulating material 120 is composed of a fibrous material including a plurality of fibers 130 . The fastening material 140 consists of a thread that just passes through the porous insulating material 120 and the holes 180 provided on the radiation shield 160 . Thus, the isolation material 120 is sewn onto the radiation shield 160 . The insulating layer 100 is disposed in a vacuum.

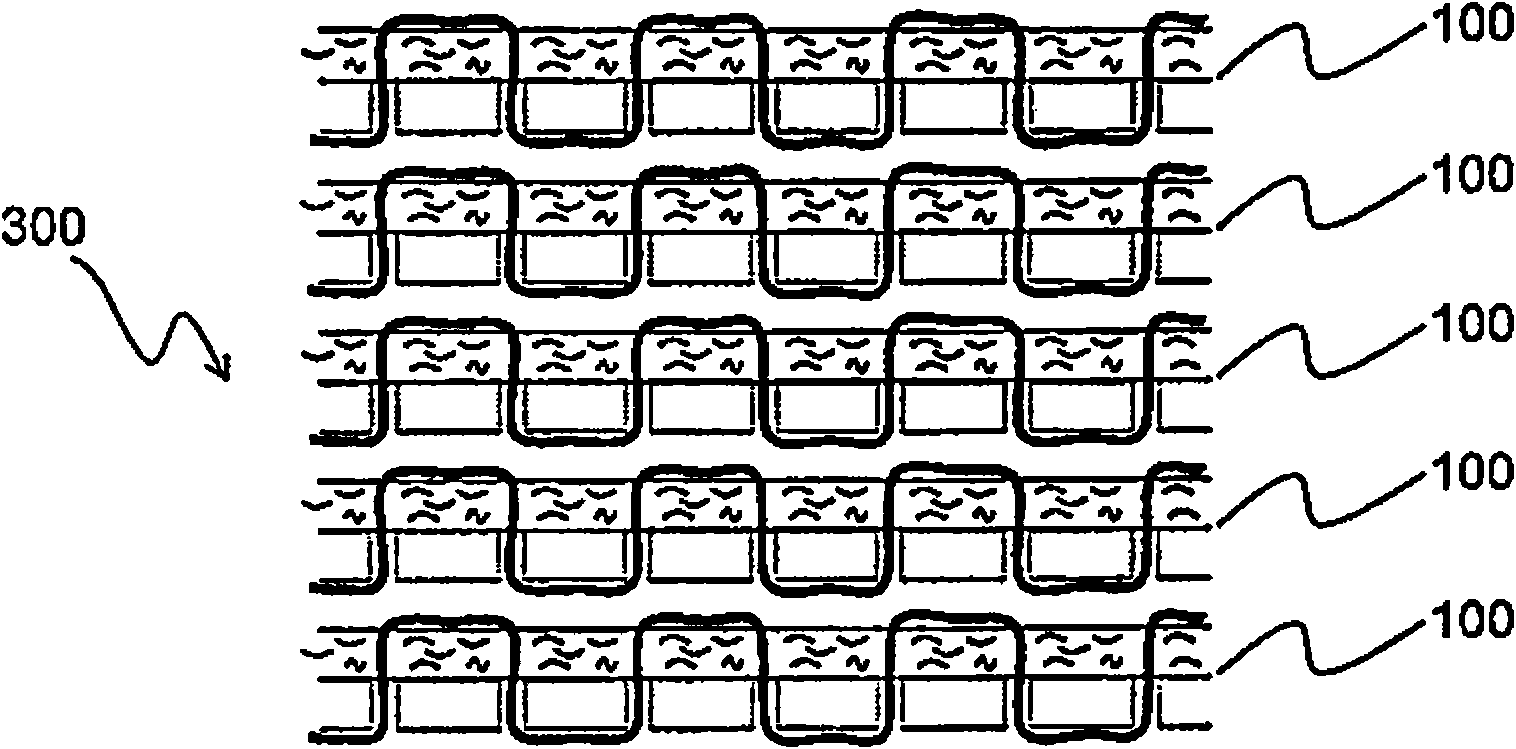

[0038] exist image 3 , showing according to figure 2 The five insulating layers 100 form an insulating member 300, also referred to as a multilayer insulating member. The insulating layer 100 is arranged such that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com