Spinning device for polyester staple fibers for filling

A spinning device and polyester staple fiber technology, applied in the field of polyester staple fiber production equipment, can solve the problems of affecting fiber elasticity and poor fiber elastic recovery rate, so as to increase stretch rate, improve elastic recovery rate, improve natural and The effect of the maximum draw ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

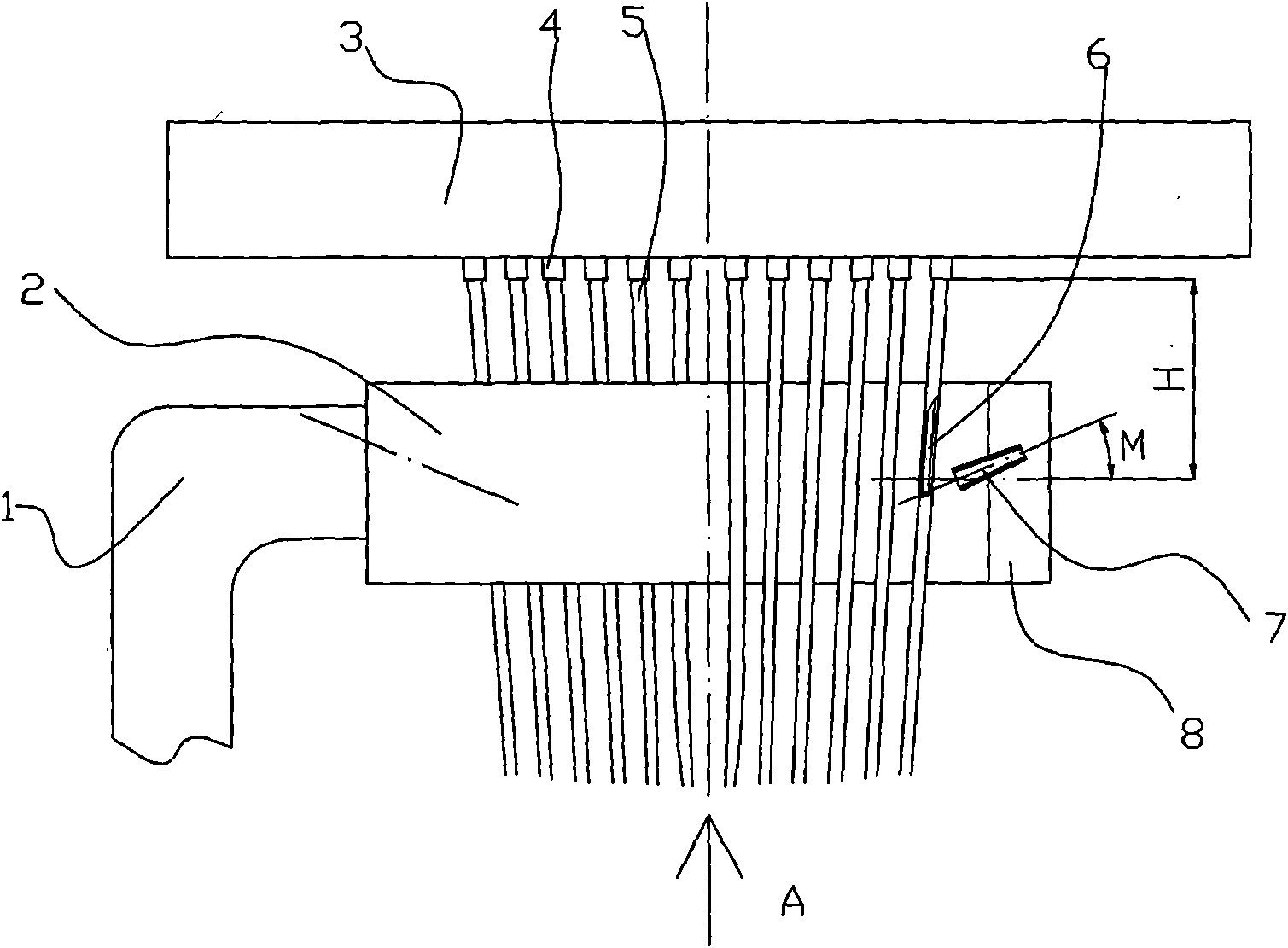

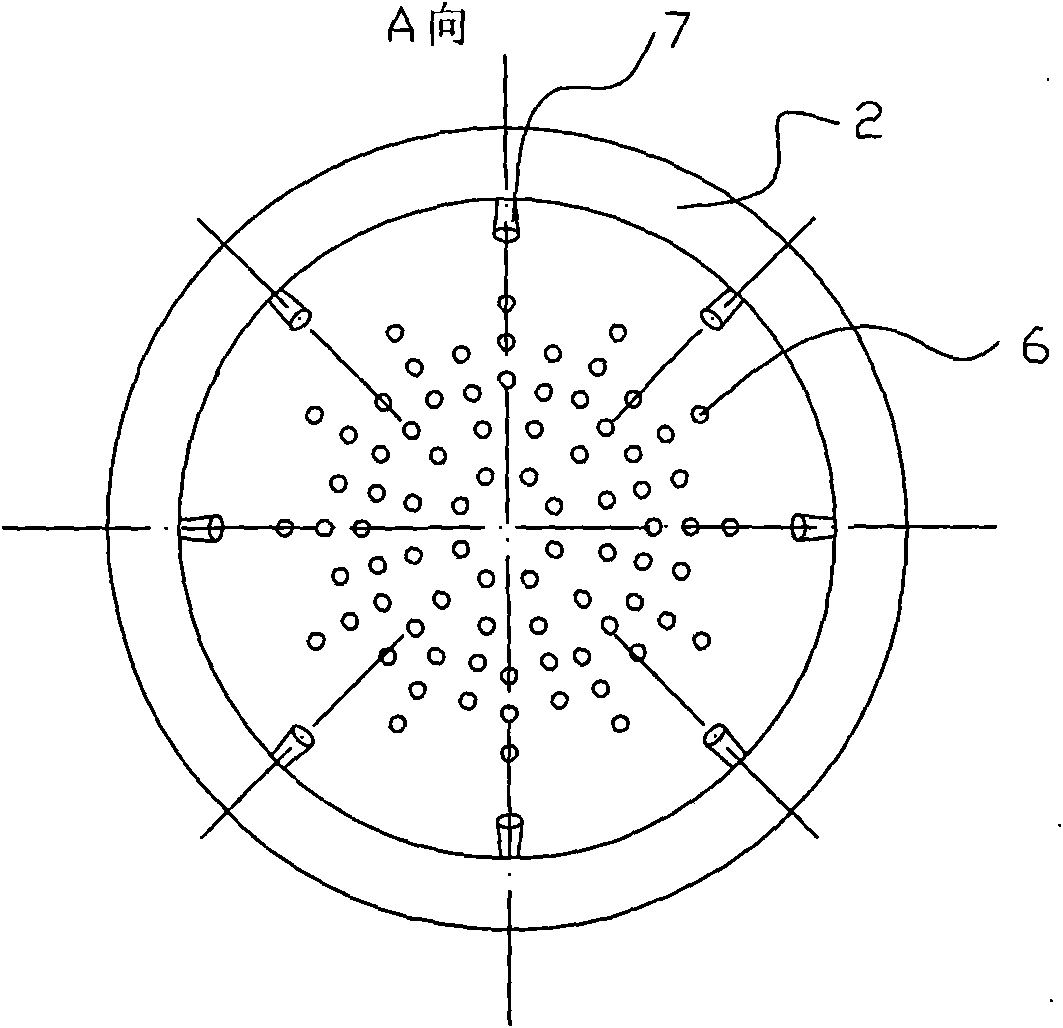

[0011] The present invention as figure 1 , 2 As shown, it includes a spinneret 3, a number of nozzles 4 arranged at the bottom of the spinneret 3, and a blowing device 2 arranged around the spray path of the nozzle 4. The blowing device 2 is ring-shaped as a whole, and several nozzles are arranged on the inner surface of the ring. The blowing outlet 7 is arranged on a circle perpendicular to the spinning path, and the distance H between the blowing outlet 7 and the nozzle 4 is 15-25 cm. Air duct 8 is arranged in the ring wall of blowing device 2, and blowing device 2 is supplied with air by an air inlet duct 1, and air inlet duct 1, air duct 8, and blowing port 7 are connected.

[0012] The air outlet 7 is inclined downward, and the inclination angle M is 5-25°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com