C60 nano monocrystal assembly materials in different shapes and preparation method thereof

A nano-single crystal and assembly technology, which is applied in polycrystalline material growth, single crystal growth, single crystal growth, etc., can solve the problem of not finding C60 single crystal assembly, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

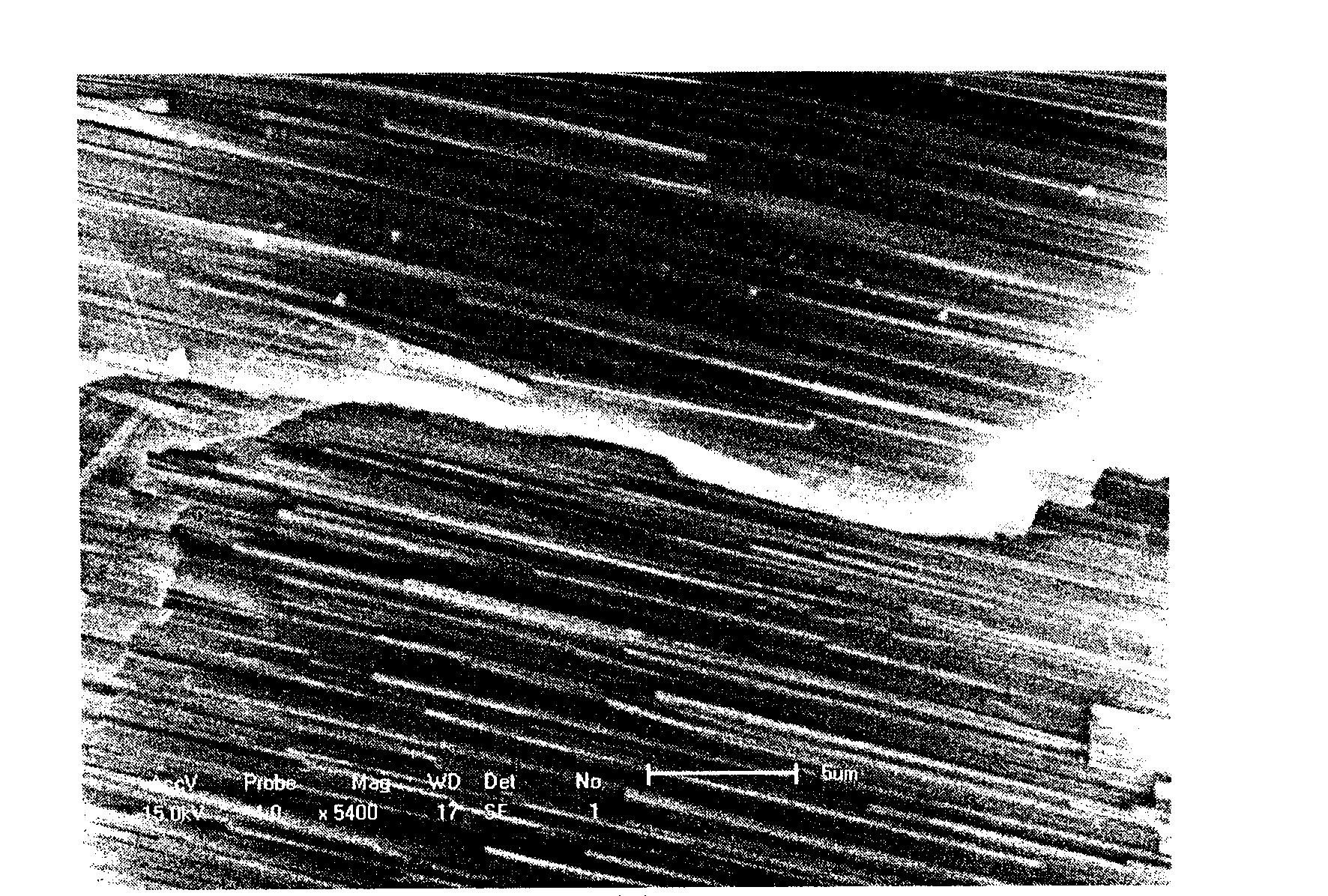

[0026] Embodiment 1 provides a specific preparation of micron tubular C 60 Examples of nano-single crystal assemblies.

[0027] Choose saturated C 60 Toluene solution was used as the mother liquor, and m-xylene was selected as the shape control agent. Pipette the prepared saturated C 60 Add 0.3 microliters of toluene solution dropwise to clean substrates such as silicon wafers and glass sheets that do not react with the solution to form a layer of solution film, drop 0.1 microliters of m-xylene next to the liquid film, and place the two Put it in a 9cm×9cm×4cm container, cover it with a glass plate, and wait for 30-40 minutes at room temperature (25°C) for the solution to volatilize, and then get a micron tube with a diameter of 2-8 μm on a silicon wafer or a glass wafer. C 60 Nano single crystal assembly, the assembly unit is C with a diameter of 200-300nm 60 Nano stave. at 10 -5 Under the pressure of Pa, at a temperature of 120-150 ° C, heat to remove the residual sol...

Embodiment 2

[0029] Embodiment 2 provides a specific preparation of microrod-shaped C 60 Examples of nano-single crystal assemblies.

[0030] Choose saturated C 60 Toluene solution was used as the mother liquor, and m-xylene was selected as the shape control agent. Pipette the prepared saturated C 60 Add 0.3 microliters of toluene solution dropwise to clean substrates such as silicon wafers and glass sheets that do not react with the solution to form a layer of solution film, drop 0.1 microliters of m-xylene next to the liquid film, and place the two Put it in a container of 9cm×9cm×4cm, and cover it with a glass plate. At 0°C, after 1-1.5 hours, the solution evaporates, and micron rods with a diameter of 2-5 μm are obtained on a silicon wafer or a glass wafer. C 60 Nano single crystal assembly, the assembly unit is C with a diameter of 200-400nm 60 Nano stave. at 10 -5 Pa pressure, 120 ℃ ~ 150 ℃ temperature, heating to remove the residual solvent to obtain C with a face-centered cu...

Embodiment 3

[0032] Embodiment 3 provides a concrete preparation nanoflower cluster-like C 60 Examples of nano-single crystal assemblies.

[0033] Choose saturated C 60 Toluene solution was used as the mother liquor, and m-xylene was selected as the shape control agent. Pipette the prepared saturated C 60 Add 0.3 microliters of toluene solution dropwise to clean substrates such as silicon wafers and glass sheets that do not react with the solution to form a layer of solution film, drop 0.3 microliters of m-xylene next to the liquid film, and place the two Put it in a container of 9cm×9cm×4cm, cover it with a glass plate, and wait for the solution to volatilize for 2 to 3 hours at a temperature of -10°C, and get nanoflowers with a diameter of 80 to 150 μm on a silicon wafer or a glass wafer Clustered C 60 Nano group single crystal device, its constituent unit is C with a diameter of 200-300nm 60 Nanorods, assembled from a center radiating outward. at 10 -5 Pa pressure, 120 ~ 150 ° C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com