Process method for nitriding austenitic stainless steel material

A technology of austenitic stainless steel and process method, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., to achieve the effect of simple process, easy promotion and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

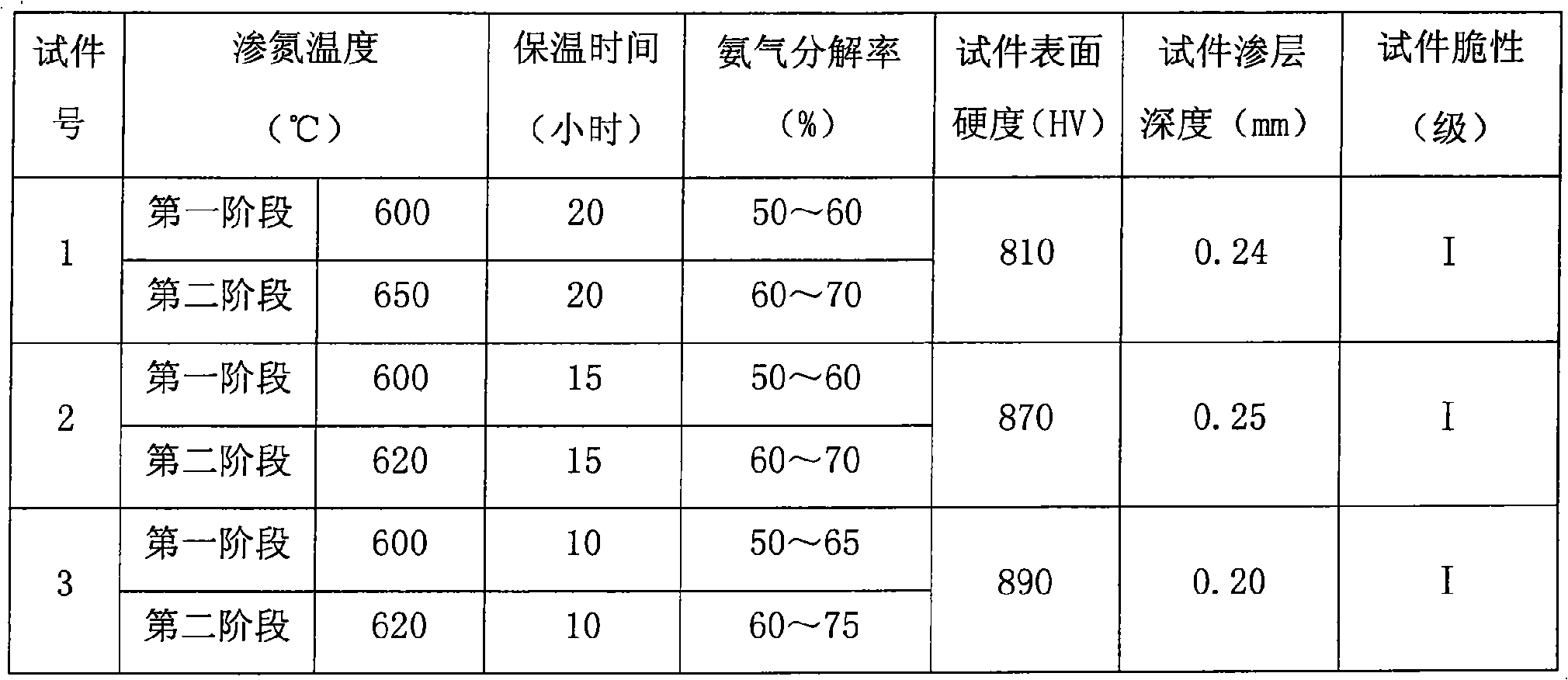

Examples

Embodiment

[0014] Next, nitriding treatment is carried out on the austenitic stainless steel specimens whose material is 1Cr18Mn8Ni5N, and all three specimens are processed into the specifications of Φ10×20mm, put into ordinary electric furnace, and annealed at 810°C for 2 hours;

[0015] Clean test pieces 1 and 2 with gasoline, clean test piece 3 with acetone, and blow dry;

[0016] Mix 8g of ammonium chloride and 390g of quartz sand evenly, place them at the bottom of the nitriding box, and then add 80g / m 3 ammonium chloride. The important function of adding ammonium chloride is to use it to decompose in the nitriding furnace to generate HCI, remove the passivation film on the surface of the workpiece, and it also has the effect of promoting the formation of metal nitrides;

[0017] Put the test pieces on the trays in the nitriding box respectively, seal the nitriding box well, and feed ammonia gas until the ammonia decomposition rate is zero, push the nitriding box into the furnace, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com