Multifunctional test system for performance test of electronic throttle valve

An electronic throttle and multi-function testing technology, applied in the field of testing, can solve the problems of affecting research and development progress, reducing work efficiency, and high personnel requirements, and achieve the effects of improving product quality, enhancing safety, and reducing economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

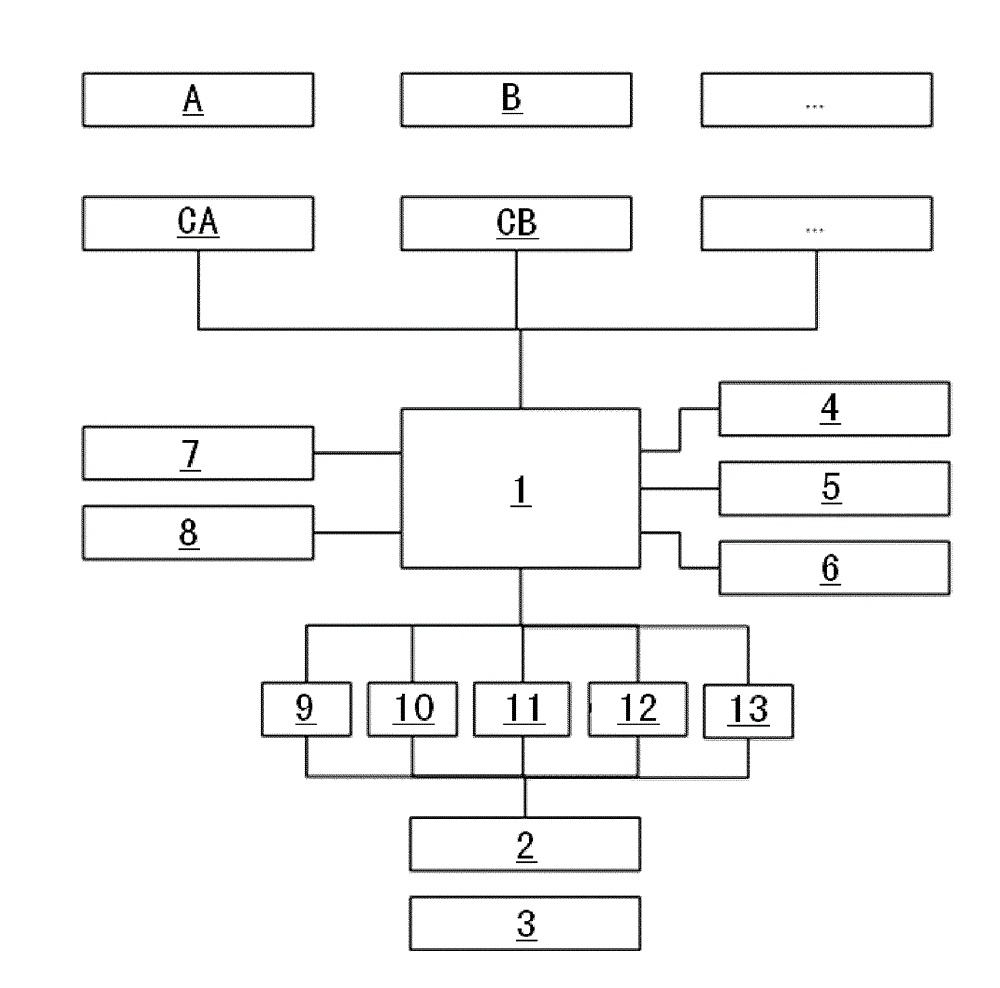

[0024] It should be noted that the working principle, composition, characteristics and advantages of the multifunctional testing system for electronic throttle performance testing of the present invention will be specifically described below by way of example, but all descriptions are only for illustration , but should not be construed as forming any limitation on the present invention.

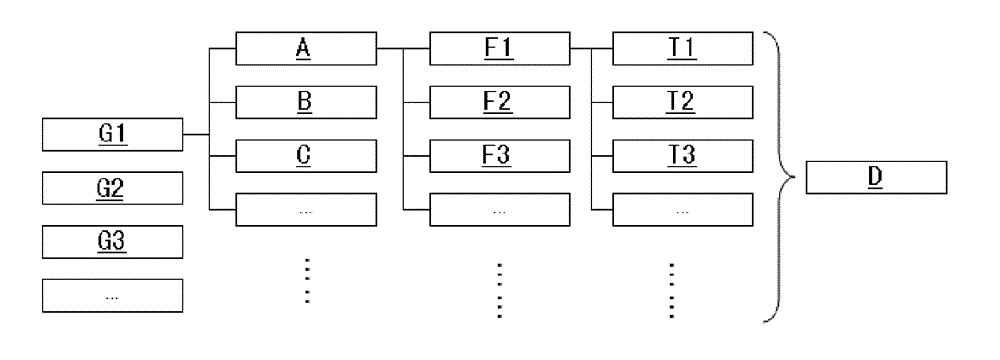

[0025] see figure 2 , which schematically shows the basic process of testing multiple performance items of the electronic throttle according to the present invention.

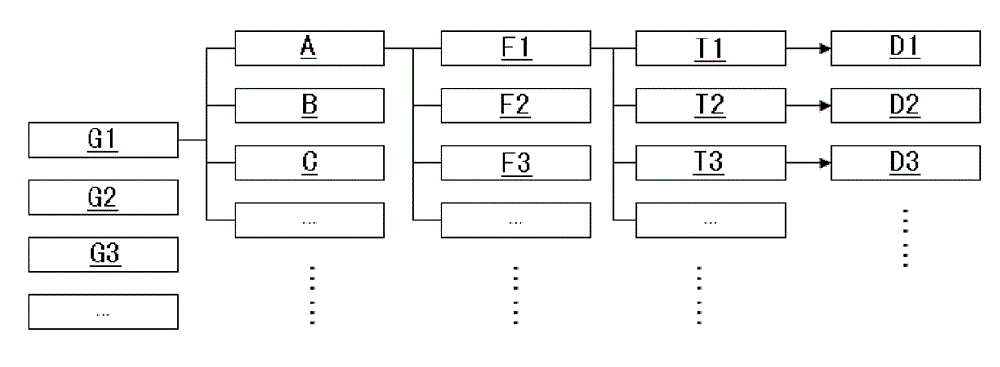

[0026] Such as figure 2 As shown, for the various performance test requirements of electronic throttle products that may have a series of G1, G2, G3... and may have A, B, C... and many other models under each series at the same time, the present invention The design ideas and solutions adopted are completely different from those of figure 1 Existing mode shown in, that is, no matter for any type of electronic throttle pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com