Catalyst system for ethylene polymerization

A catalyst and system technology, applied in the direction of organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the inconvenience of production and operation, the inability to produce high molecular weight polymers, Can not produce ethylene oligomers and other problems, to achieve the effect of simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

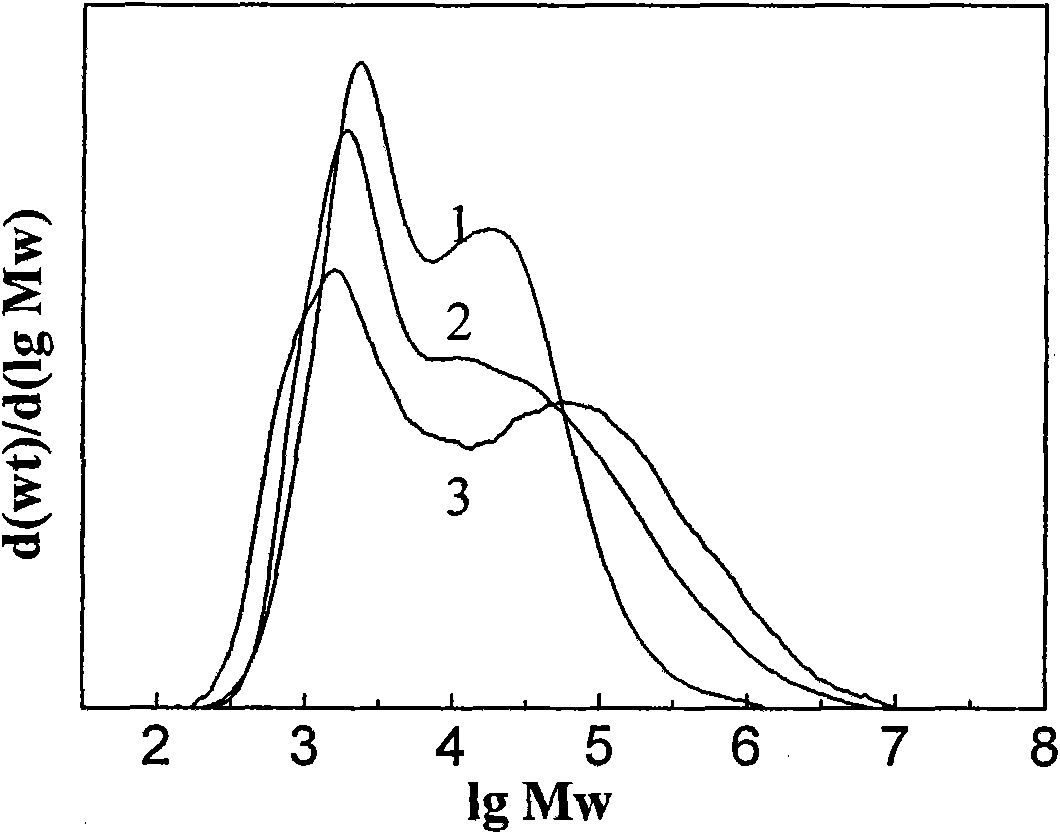

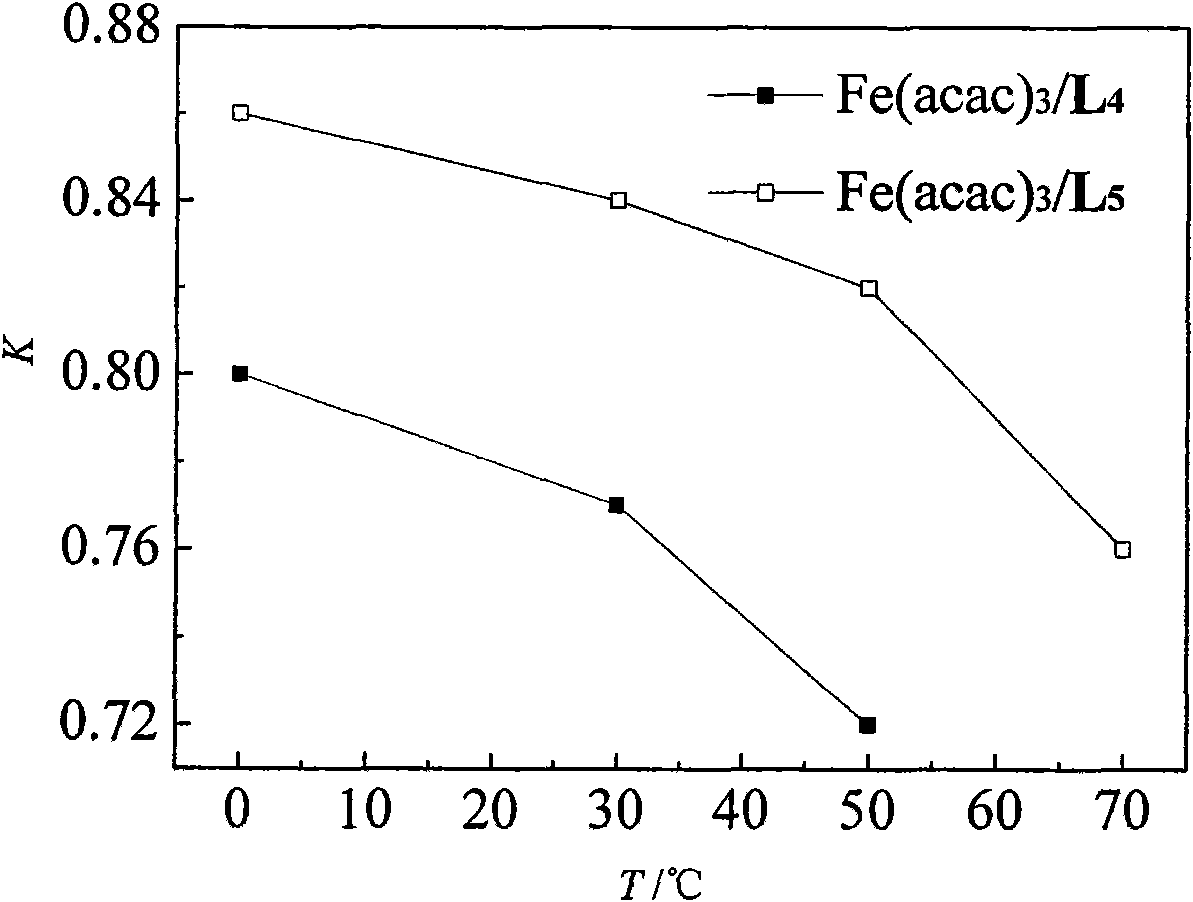

Image

Examples

preparation example Construction

[0048] Preparation of pyridinediimine ligand

[0049] (1) 2,6-bis[1-(2,6-dimethylphenylimino)ethyl]pyridine (L 1 )Synthesis

[0050] Dissolve 3g (18.4mmol) of 2,6-diacetylpyridine and 8.9g (73.6mmol) of 2,6-dimethylaniline in 50ml of absolute ethanol, add 5 drops of glacial acetic acid, and heat to reflux for 48h. The system was cooled to room temperature, most of the solvent was distilled off under reduced pressure, and crystallized at -18°C. After suction filtration, it was dissolved in 25ml of hot alcohol and crystallized at -18°C. Suction filtration, drying, and weighing obtained 4.83 g of solid, namely 2,6-bis[1-(2,6-dimethylbenimino)ethyl]pyridine, with a yield of 71.0%.

[0051] (2) 2,6-bis[1-(2-methyl-6-isopropylphenylimino)ethyl]pyridine (L 2 )Synthesis

[0052] Dissolve 3g (18.4mmol) of 2,6-diacetylpyridine and 11g (73.6mmol) of 2-methyl-6-isopropylaniline in 50ml of absolute ethanol, add 5 drops of glacial acetic acid, and heat to reflux for 48h. The system was...

Embodiment 1

[0068] In a 250ml glass reactor, add 100ml of toluene and keep the temperature at 30°C. Then add 2umol2,6-bis[1-(2,6-dimethylbenimino)ethyl]pyridine (L 1 ), 2umol iron acetylacetonate and 400umol MAO. Feed ethylene gas under stirring, the ethylene pressure is normal pressure, react for 30 minutes, terminate the reaction with 10ml hydrochloric acid ethanol solution with a weight percent concentration of hydrochloric acid of 10%, filter the solvent, and vacuum dry at 50°C to obtain the poly vinyl. This reactivity is 3.00×10 6 g polyethylene / (mol Fe·hatm). The properties of polyethylene are shown in Table 1.

Embodiment 2

[0070] In a 250ml glass reactor, add 100ml of toluene and keep the temperature at 30°C. Then add 2umol2,6-bis[1-(2-methyl-6-isopropylphenylimino)ethyl]pyridine (L 2 ), 10umol cobalt acetylacetonate and 3000umol MAO. Feed ethylene gas under stirring, the ethylene pressure is normal pressure, react for 30 minutes, terminate the reaction with 10ml hydrochloric acid ethanol solution with a weight percent concentration of hydrochloric acid of 10%, filter the solvent, and vacuum dry at 50°C to obtain the poly vinyl. This reaction activity is 7.10×10 4 g polyethylene / (mol Fe·hatm). The properties of polyethylene are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com